- Effect of Contact Pressure on Reciprocating Wear Behavior of PEEK, PTFE, and UHMWPE

Liu Lian, Duan Haitao†

, Jia Dan, Tu Jiesong, Zhan Shengpeng, Li Yinhua,

Luo Xiaoshuang, Zhan Wen, Xiong Wei, and Li Jian†

, Jia Dan, Tu Jiesong, Zhan Shengpeng, Li Yinhua,

Luo Xiaoshuang, Zhan Wen, Xiong Wei, and Li Jian†

State Key Laboratory of Special Surface Protection Materials and Application Technology, Wuhan Research Institute of Materials Protection, Wuhan 430030, Hubei, China

- 접촉 압력이 PEEK, PTFE 및 UHMWPE의 왕복 마모 거동에 미치는 영향

Engineering plastics are

macromolecular compounds composed of covalently bonded macromolecules, which

have been widely used in sliding wear-resistance materials in isolation

bearings. In this study, an MFT-5000 reciprocating friction testing machine was

used to compare the friction and wear performance of polyetheretherketone

(PEEK), polytetrafluoroethylene (PTFE), and ultra-high molecular weight

polyethylene (UHMWPE) under heavy load conditions in dry friction condition.

The results show that load has a significant effect on the friction

coefficient, wear rate, and wear mechanism of three materials. The instant

friction coefficient of PTFE fluctuates under high load, the wear rate clearly

increases with the increase in load. Therefore, the application under high load

conditions is limited. The wear rate of UHMWPE is the least affected by the

load among the three materials. Even when the load exceeds the yield strength,

the wear resistance is still good. The friction coefficient of PEEK decreases

with the increase in load but maintains a high value that restricts its

application in sliding friction pair materials to some degree.

load, engineering plastics,

dry friction, reciprocating friction, wear

The friction and wear performance of PEEK, PTFE, and

UHMWPE under heavy load conditions in dry friction condition was studied. Load

has a significant effect on the friction coefficient, wear rate, and wear

mechanism of three materials.

Engineering plastics are macromolecular compounds composed of covalently

bonded macromolecules, which have been widely used as mechanical moving parts

instead of steel. The American Society for Standard Testing of Materials (ASTM)

defines engineered plastics as plastics or polymer compounds having certain

properties. Due to the characteristics of high strength, low density, good self-lubricating

performance, and a relatively low friction coefficient (refers to the ratio of

the friction force between two surfaces and the vertical force acting on one

surface), engineering plastics are widely used as friction auxiliary materials

under special stress conditions such as isolation bearings for bridges and

sealing parts.1-4 Isolation bearings are used to bear and connect

the upper buildings and lower foundation. Their main function is to offset

seismic energy to achieve seismic isolation by using sliding bearing materials

and sliding panel as the reset function of movement of the reciprocating

friction. Sliding materials are mainly polytetrafluoroethylene (PTFE),

ultra-high molecular weight polyethylene (UHMWPE) and their composites, while sliding

plates are mainly composed of 06Cr19Ni10 stainless steels.5,6 The

contact load of the friction pair can exceed 50 MPa, far exceeding the

yield strength of polymer materials such as PTFE and UHMWPE,7 which

is a required condition of supercritical load. Studies have shown that PTFE is

easily cooled and has a high wear rate under high load.8-10 UHMWPE

has excellent tribological properties.11,12 However, the question

arises as to whether its unique flow stress behavior beyond the yield strength

affect the application of friction pairs under heavy loads. It is known that

polyetheretherketone (PEEK) has the characteristics of high strength, good wear

resistance, good chemical resistance.13,14 Hence, it is worth

exploring whether PEEK can be used as a friction pair material in shock

absorption structures.

The influence of the contact stress (load) on the friction and wear

behavior of engineering plastics has always been a subject of interest. A few

researchers have investigated the influence of loads on the tribological

properties of PTFE, UHMWPE and PEEK under different experimental parameters.

Jia et al. studied the self-lubricating properties of PTFE and its

nano-composites under loading conditions in the range of 1.43-8.55 MPa.15

Saikko studied the influence of load on the multidirectional sliding friction

and wear of UHMWPE.16 Laux compared the friction and wear behavior

of PEEK under 1.8 and 3.9 MPa loads.17 Rodriguez et al.

studied the dry reciprocating sliding friction wear performance of PEEK under

the loads of 4, 8, and 10 MPa, respectively.18 Zhang et al.

investigated the effect of amorphous PEEK on the wear mechanism under different

loads (1-9 N).19 Under low load condition, the experimental

parameters and materials show that the friction coefficient decreases with the

increase in load, and the wear mechanism differs with the increase in load. A

few researchers have conducted comparative studies on the friction and wear

behavior of different types of engineering plastics under different loads.

Huseyin et al. studied the tribological properties of PEEK, UHMWPE,

glass-fiber reinforced PTFE, and other composite materials under different

loads (50, 100, and 150 N) under dry friction and lubricating medium,

respectively.20 Zhiwei et al. studied the tribological

properties and wear mechanisms of PTFE, PEEK, and thermosetting resins under

low loads (15-60 N) by using a pin disc tester.21 Wang et al.

studied the tribological behavior of dry reciprocating sliding and fretting

friction of six polymer materials including UHMWPE, PTFE, phenolic aldehyde,

p-hydroxybenzaldehyde (PHBA), PEEK, and polyimide (PI) and GCr15 steel under 10

N load.22 H. Unal et al. investigated the effect of loads

(20, 30, and 40 N) on the friction and wear behavior of polyamide-6 (PA 6), polyformaldehyde

(POM), and UHMWPE.23 The above studies have compared the

tribological properties of different materials under low loads, and the

relevant experimental studies have focused on the tribological properties under

the load range below the yield strength of the materials. Few studies have attempted to

understand the laws of friction and wear performance of engineering

plastics under the condition of large loads exceeding the yield strength of

materials. The change compared to the case of low loads needs to be examined in

detail.

This work focuses on three engineering plastics i.e. PTFE, UHMWPE, and

PEEK, and uses MFT-5000 reciprocating friction and wear testing machine (Rtec

Instrument, USA) to determine the friction coefficient and wear rate under different

loads (10, 15, 20, 25, and 30 MPa). Using scanning electron microscopy (SEM),

white light confocal 3D topography, and energy dispersive X-ray spectrometry

(EDS), we have comparatively studied the wear surface morphology and discussed

the wear mechanisms of the three materials under different loads.

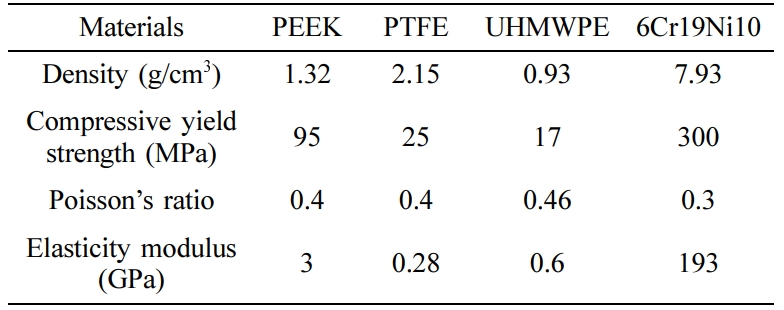

Materials. Three

commercial-grade engineering plastics (PTFE, UHMWPE, and PEEK) pin samples and

06Cr19Ni10 steel plate samples were used as friction pairs in the experiment.

Their material properties were obtained from the Shenzhen senli plastic

material co. Ltd, as shown in Table 1. The pin samples were prepared by turning

the engineering plastic bars. The diameter of the frictional contact between

the pin samples and steel plate samples was 2.52 mm. The 06Gr19Ni10 steel plate

was cut into 30×30×3 mm using wire cutting. The friction surface of the

samples was mirror polished by metallographic polishing. The size and the

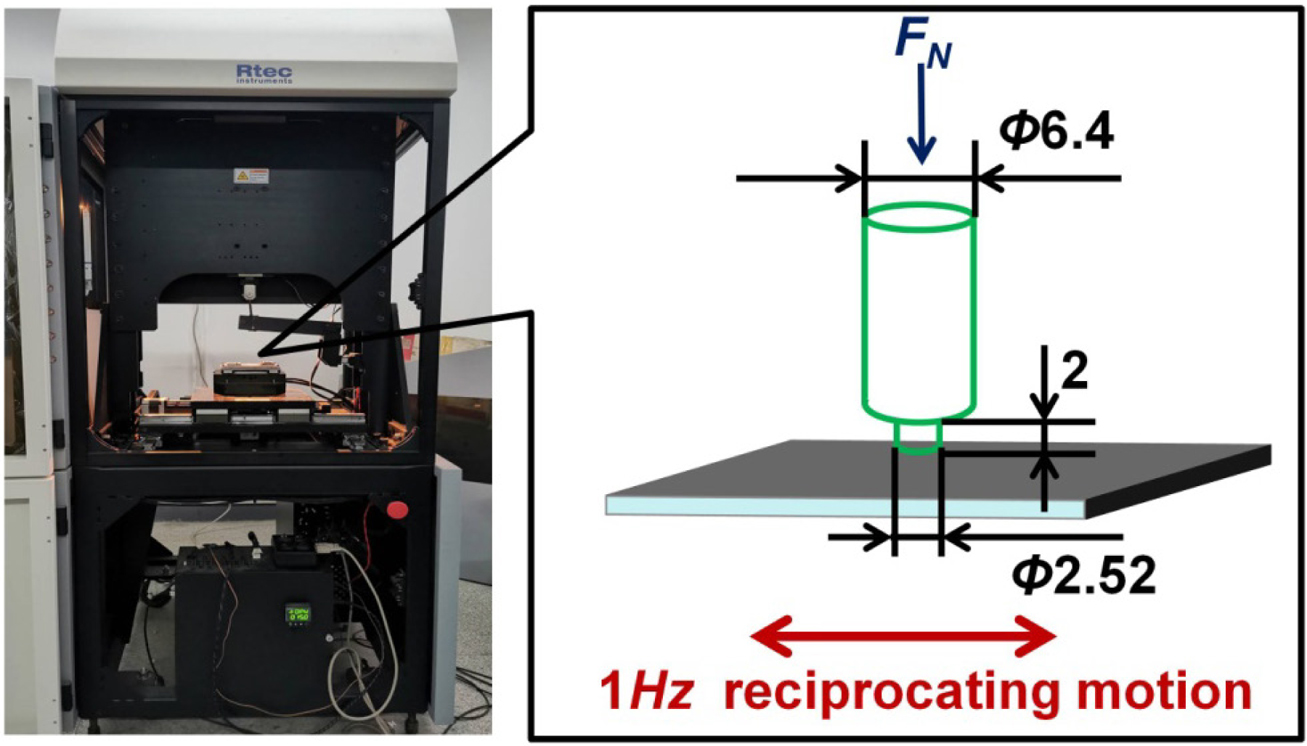

contact form of the friction pair are shown in Figure 1.

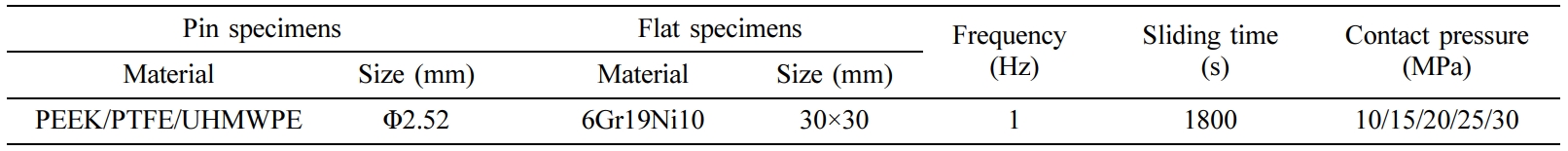

Design. In order to

achieve the specific pressure conditions required for the experiment and ensure

the stable operation of the experimental equipment. The contact pressure was

calculated as 30 MPa when the testing machine pressure was 150 N. The

radius of the friction pin was calculated as R=1.26 mm. The

engineering plastics are machined to the corresponding size by turning.

The engineering plastic pin samples and 06Gr19Ni10 piece samples were

installed on the MFT-5000 reciprocating friction and wear tester (Rtec

Instrument, USA) to conduct reciprocating sliding wear tests. The experimental

method was dry rubbing under ambient temperature at 25 ℃ and relative

humidity 70%. Before the test, the sample was cleaned by ultrasonic rays with

anhydrous ethanol. In order to study the influence of load variation on the

friction and wear properties of different engineering plastics, all the

friction tests were conducted for 30 min under the condition of

reciprocating friction frequency of 1 Hz and a contact pressure of 10, 15, 20,

25, and 30 MPa, respectively. The specific experimental parameters are

shown in Table 2. After the test, the pin sample was removed from the test

machine, soaked in anhydrous ethanol reagent for ultrasonic cleaning for 180 s,

placed in an oven at a temperature of 40 ℃ for 24 h, and then removed and

stored in a drying dish for analysis.

Characterization. SEM (JSM-6510LV),

white light confocal microscopy (CM, Micromeasure2 STLE France), and EDS were

used to characterize the microscopic morphology and chemical composition of the

worn surface, observe the wear morphology of the three engineering plastic

samples under different loads, and discuss the law of influence of the load on

the wear mechanism of the three materials. After the samples were dried in the

oven, a precision analytical balance (precision ± 0.0001 g) was used to

measure the mass loss of the friction pins five times. Then, the average

value was converted to the material wear rate W (refers to the volume of

wear per unit of load per unit of length) by the following calculation

method:24

W = Dm/(r × F × d)[mm3/(Nm)] (1)

Where, ρ is the material

density (g/mm3), F is the normal load (N), and d is the

friction sliding distance (m).

|

Figure 1 Schematic diagram of the contact and size of the friction

pair. |

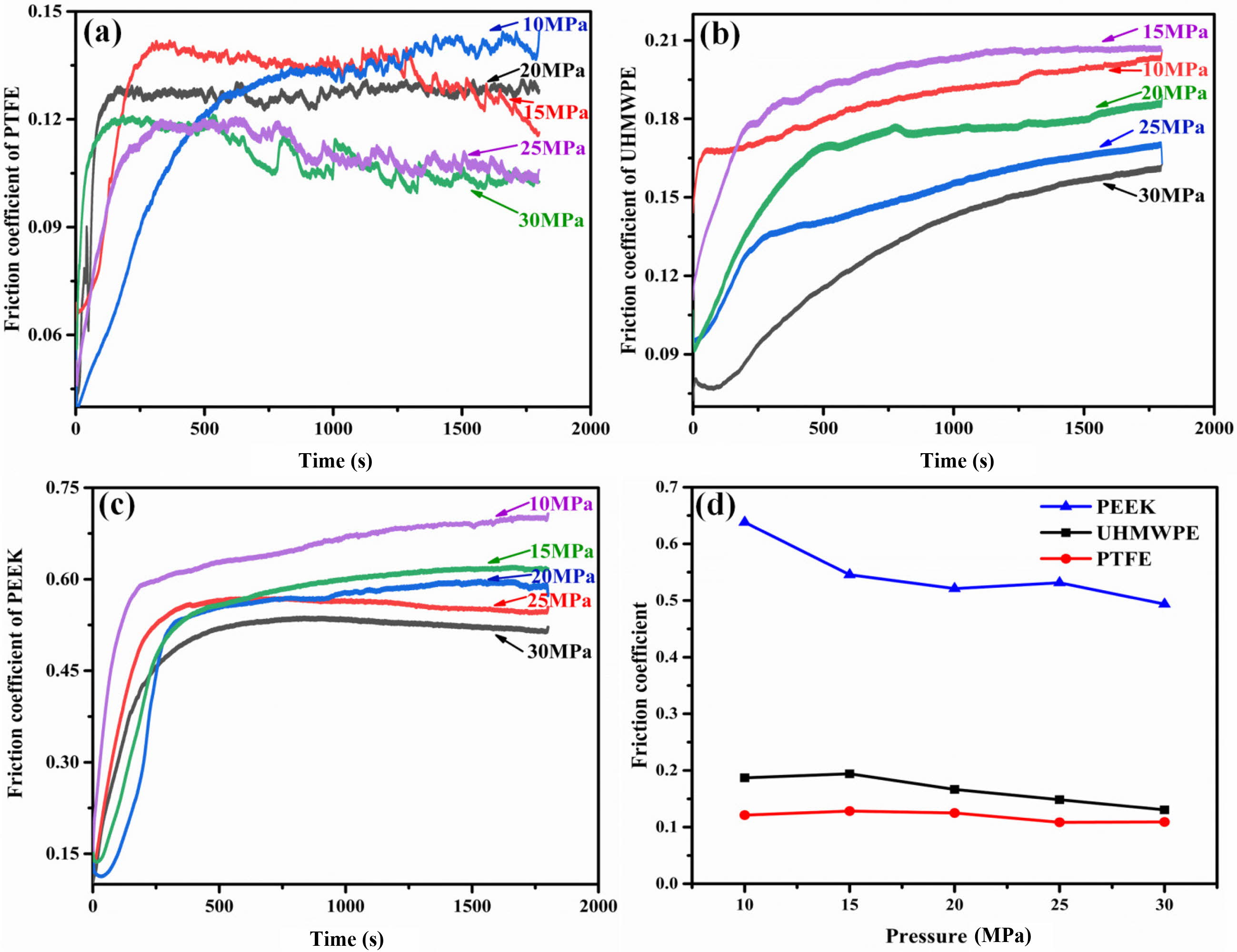

Influence of Load on the Friction Coefficient of Materials. Figure 2(a-c)

shows the variation of the friction coefficient with reciprocating sliding time

of PTFE, UHMWPE, and PEEK under different loads, respectively. The friction

coefficient curves of the three engineering plastics all show the

characteristics of rapid rise and then smooth transition. The rapid rise stage

is short, approximately 100-400 s. The initial slope of PTFE in the early

rise stage increases with the increase in the load, while the time to enter the

stable stage decreases. When the experimental load (10 and 15 MPa) is

lower than the yield strength of the material, the slope is small, and the time

to enter the stable friction state is longer. When the experimental load

reaches 30 MPa, the time to enter the stable period is the shortest. When

the experimental load is greater than the yield strength (> 20 MPa),

the friction coefficient in the stable stage decreases. In the early friction

rise stage of UHMWPE, the trend is opposite to that of PTFE i.e. the slope decreases

with the increase in load. When the experimental load (30 MPa) is greater

than the yield strength condition, the friction coefficient gradually decreases

in the initial stage and then gradually increases. After reaching the stable

friction state, the friction coefficient of UHMWPE still presents a trend of

slow increase. In the early rising stage of PEEK, the slope does not change

markedly with load variation. After reaching the stable stage, the friction

coefficient still increases slowly under the experimental load of 10–20 MPa,

while the friction coefficient is relatively stable under the experimental load

of 25 and 30 MPa.

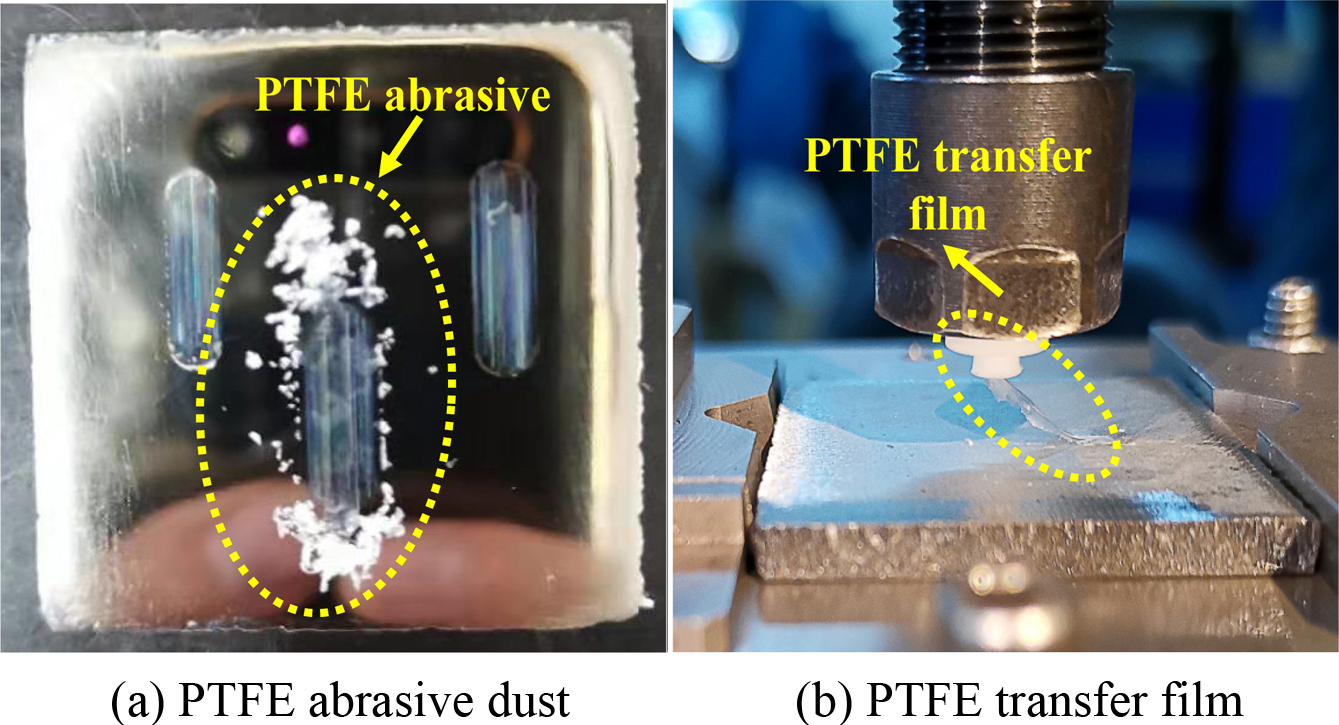

It can be observed from Figure 2 that the friction coefficient of the

three materials in the stable stage all show a trend of decrease with the

increase in load. Compared with PEEK and UHMWPE, the friction coefficient of

PTFE appears to have the most fluctuation. The friction coefficient fluctuates

more clearly for greater load. The reason is that: PTFE has poor mechanical

properties i.e. its surface material wears off most easily in the process of

friction, and as abrasive dust is formed on the friction interface (as shown in

Figure 3(a)), the friction coefficient clearly fluctuates. The wear abrasive

dust forms a uniform transfer film on the surface of the friction pair parts

and has the effect of solid lubrication25-27 (as shown in Figure

3(b)), resulting in PTFE having the minimum friction coefficient among the

three materials.

Figure 2(d) shows the average friction coefficient of PEEK, PTFE, and

UHMWPE under different loads (the calculation method is described in Characterization

section). As shown in the figure, the average friction coefficient of

PTFE is the least, followed by UHMWPE, and PEEK is the largest. The average

friction coefficient of the three materials shows a decreasing trend with the

increase in load, while the trend is the most pronounced in PEEK. The stability

of the average friction coefficient with the variation of load is in the order

PTFE > UHMWPE > PEEK.

Influence

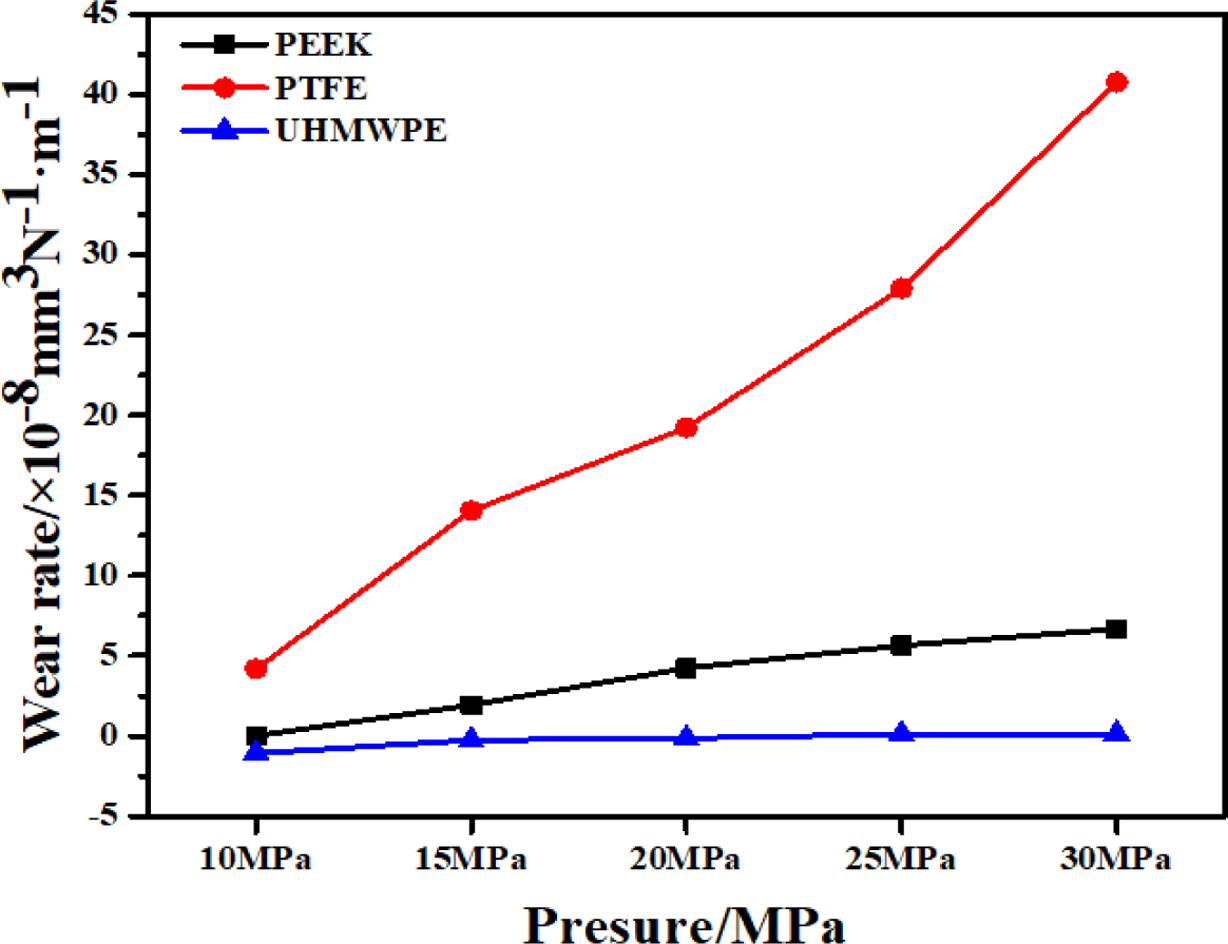

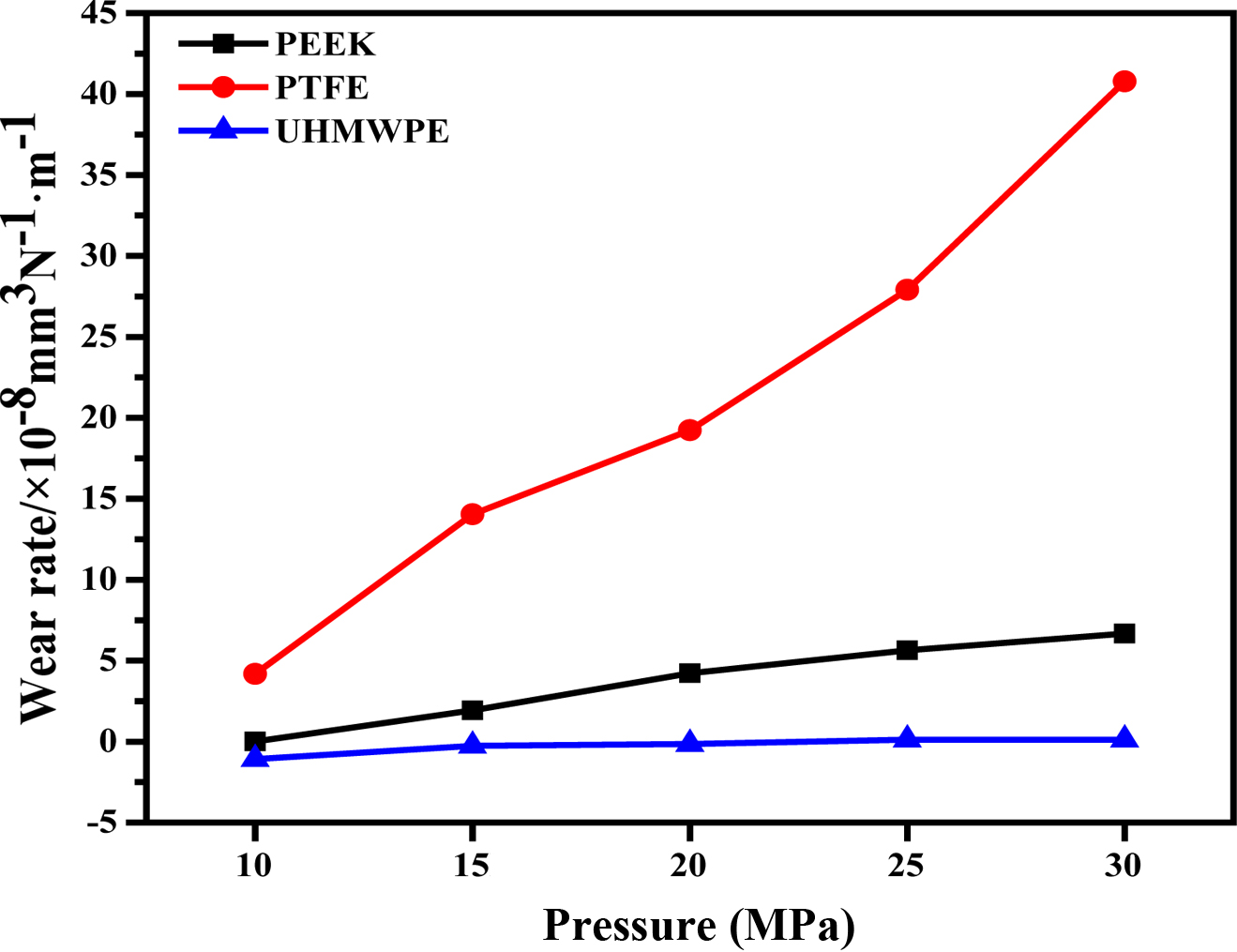

of Load on the Wear Rate of the Materials. Figure 4 shows the

relationship between the wear rate and the load of PEEK, PTFE, and UHMWPE after

30 min of sliding reciprocating friction with a frequency of 1 Hz. It can

be observed from the figure that the wear rate of the three materials increases

with the increase in the load. Under the same friction condition, the wear rate

and the rate of change are shown to vary as PTFE > PEEK > UHMWPE. The

wear rate of UHMWPE is the lowest, and the wear rate change is relatively stable,

which is 1.0753–0.1195×10-8 mm3N-1·m-1.

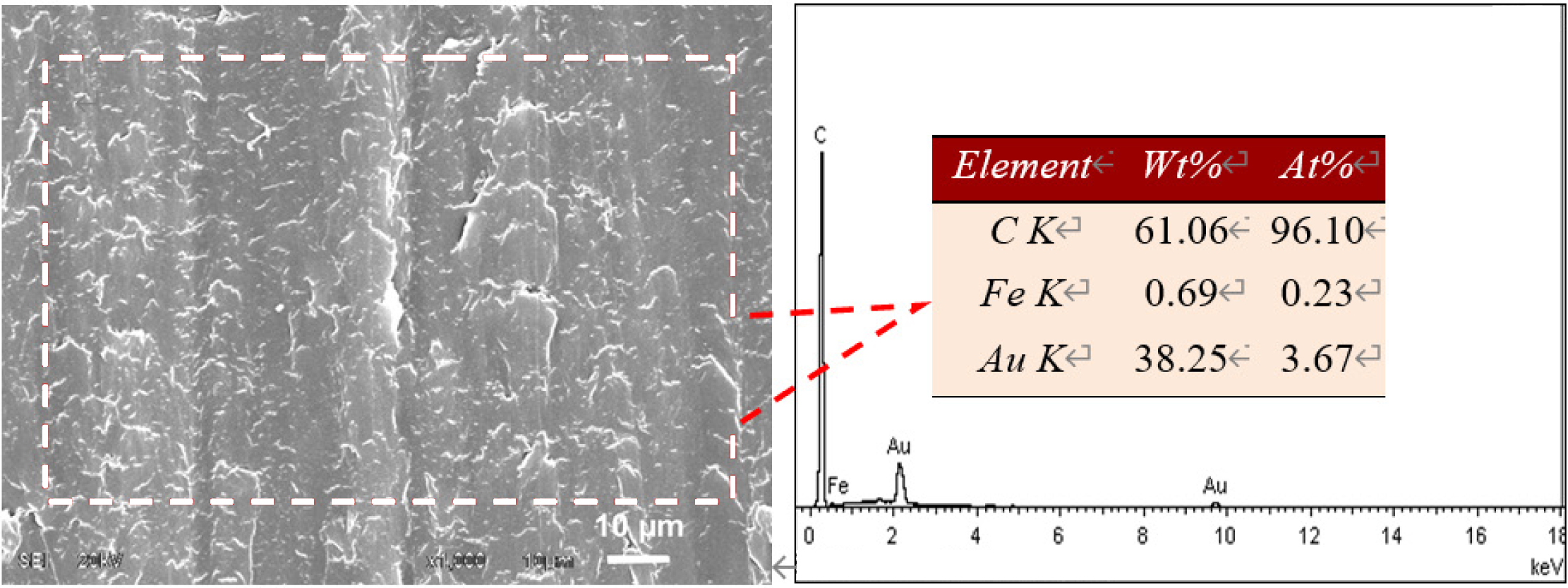

Under small

loads, the UHMWPE wear rate is negative. This may be because UHMWPE has good

wear resistance, so that the wear mass loss is low, and in the process of

friction, the elements of the steel plate pairs adhere and transfer to the

surface of UHMWPE, which results in increased friction pin quality.28

According to the element content analysis on the wear surface of the UHMWPE

friction pin (Figure 5), the worn Fe content of the UHMWPE friction pin reaches

0.69% under 15 MPa load, indicating that Fe element is transferred to the

UHMWPE surface during the reciprocating friction process, which may lead to

negative wear. With the increase in load, UHMWPE gradually deforms plastically,

which results in increased material wear. The wear weightlessness is greater

than the increased weight caused by the transfer of elements, so that the

weights of the material wear quantitative changes are positive. The changes of

the wear rate of UHMWPE are the most stable, and the absolute value is the

minimum, which shows that UHMWPE can exhibit good wear resistance even when the

load is greater than the material yield strength.

With the increase in load, the wear rate of PTFE increases almost

linearly, and when the experimental load is greater than the yield strength,

the wear rate increases much more than that at low load. The wear rate under a

load of 30 MPa is 8 times that under 10 MPa, and the load has a significant

impact on the wear behavior of PTFE. This is because the van der Waals

attraction between the PTFE molecules is small, which facilitates bond slip.

PTFE has good self-lubricating performance, and deforms with the increase in

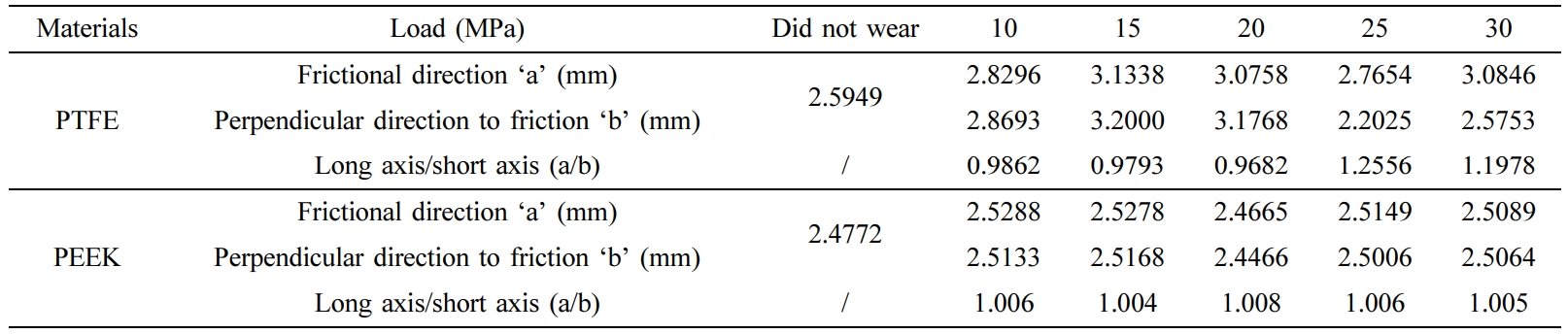

load under the condition of heavy load.29,30 Table 3 shows the pin

sample size measured by white light confocal microscopy. It can be observed

that when the test load is less than 20 MPa, the friction end surface of the

sample is basically round, and the long axis/short axis is close to 1. When the

test load is 25 MPa (close to the yield strength), the deformation of the

friction end surface of the sample increases, and it becomes longer along the

direction of friction and shorter perpendicular to the direction of friction.

At 30 MPa, under the interaction of wear, the friction end surface of the

sample presents an irregular ellipse. As the load increases, the change of diameter

ratio of the friction direction/perpendicular direction to friction of PTFE

indicates that the plastic rheology along the frictional direction is the main

factor that affects the frictional and wear properties under the loading

conditions close to and exceeding the yield strength.

The wear rate of PEEK is between 0.0561–6.6659×10-8 mm3N-1·m-1, and the wear rate

and rate of change are between UHMWPE and PTFE. Its friction

direction/perpendicular direction diameter is shown in Table 3. The shape of

the friction surface of the material basically does not change with the load,

which indicates that PEEK has relatively stable mechanical properties under

this experimental condition.

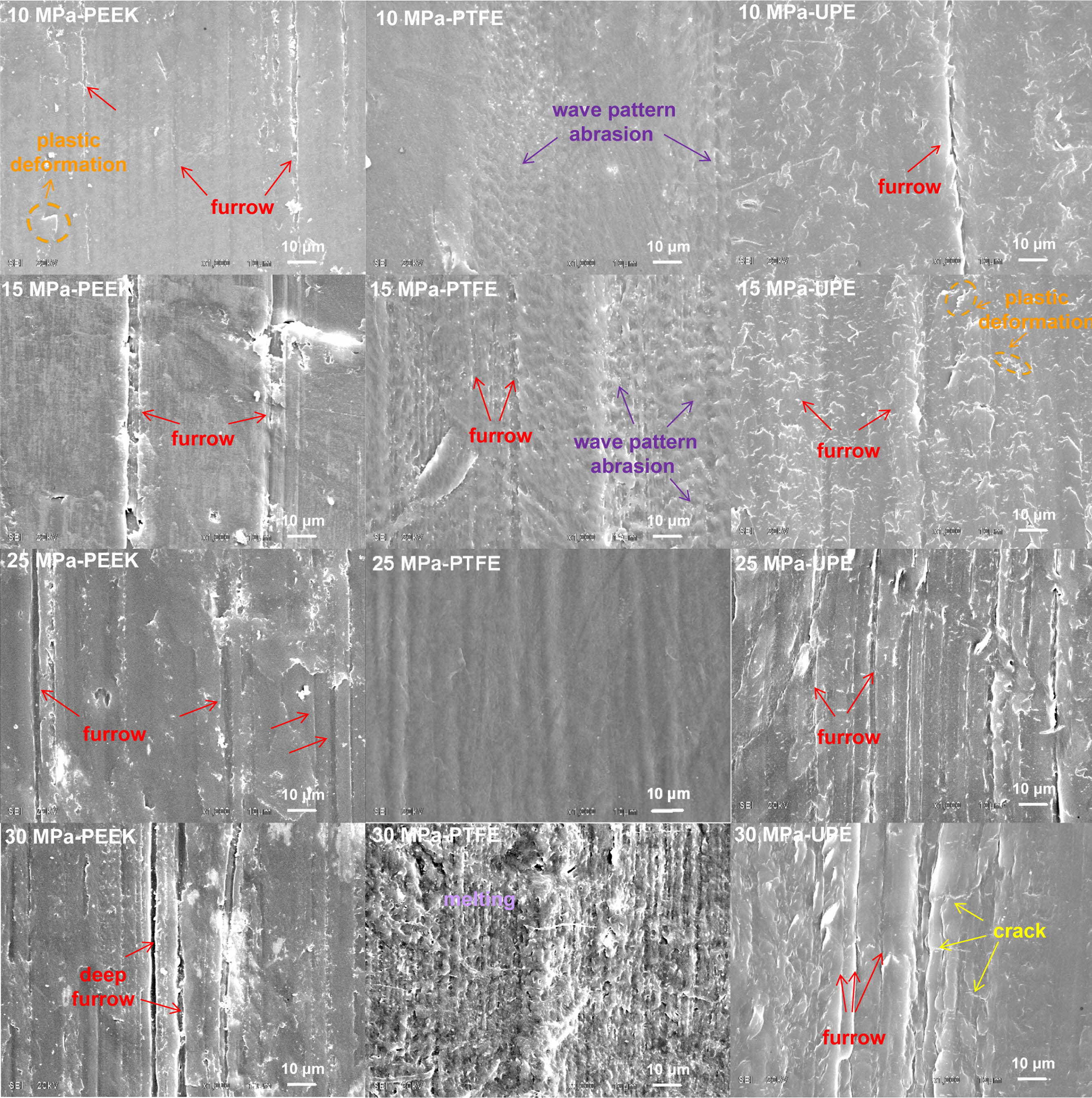

Wear

Mechanism Analysis. In order to better analyze and compare the friction and

wear mechanisms of PEEK, PTFE, and UHMWPE under different loads, the

microscopic wear morphologies of the three engineering plastics under

reciprocating friction are studied by SEM. Figure 6 shows the microscopic

surface morphologies of the three engineering plastics after reciprocating wear

and tear after magnification to 1000×. It can be observed from the figure that

the load has a significant impact on the wear morphology of the three

materials, which is discussed as follows:

The wear morphology of PTFE is complex with change of load. When the

experimental load (10 and 15 MPa) is less than the yield strength, the wear

morphology of PTFE is characterized by material folding. The material folding

under 15 MPa increases more significantly compared with that under

10 MPa, and a few furrows appear. The increase in load increases the material

flow and thus aggravates the material wear. When the experimental load (25 MPa)

is equivalent to the yield strength, the wear surface is gradually smoothed

with the increase in material flow. When the experimental load (30 MPa) is

greater than the yield strength, partial melting occurs on the surface of PTFE,

which further accelerates the wear process of the material. Therefore, the wear

rate of PTFE increases significantly with the increase in load, and the wear

rate under load greater than the yield strength changes much more than that

under lower load, which limits its application under large loads.

Simultaneously, the increase in the load shortens the shedding process of the

material in the friction process, such that the slope of the friction

coefficient increases with the increase in load in the early rising stage. Due

to the factors of material melting and stress distribution inequality, PTFE

molecular chains break, resulting in part of the flexible chain separating from

the matrix. As shown in Figure 3(b), the material separates from the matrix in

the form of a transfer film. The transfer film on the surface of the friction

pair of 6Cr19Ni10 causes the friction coefficient to have a downward trend in

the stable stage when the experimental load is greater than the yield strength.

The wear morphology of UHMWPE is also significantly affected by the load.

When the experimental load (10 and 15 MPa) is less than the yield strength,

the wear morphology of UHMWPE is mainly furrow wear. When the load increases to

15 MPa, the number of furrows on the UHMWPE surface gradually increases,

and a small amount of plastic deformation occurs. When the experimental load

(25 and 30 MPa) is greater than the yield strength, the furrows on the

surface of the material further increase in number than those under small

loads. When the load is 30 MPa, due to the effect of high cycle contact stress,

repeated deformation of the material accelerates fatigue. Hence, fatigue wear

occurs and leads to not only furrow wear but also, cracks on the surface of

UHMWPE. Therefore, the wear rate of UHMWPE increases with increase in load.

However, compared to PEEK, under the same load, the furrows are more obvious, and

hence the wear rate of UHMWPE is less than that of PEEK, indicating that the

load has an insignificant effect on the wear rate. Under the load greater than

the yield strength, both have good wear resistance, which is consistent with

the result shown in Figure 4. When the load is greater than the yield strength,

in the initial friction stage, the contact of the rough peaks of the UHMWPE

surface leads to rapid increase in the actual contact stress, and the reduction

of the friction coefficient. Subsequently, as the friction surface furrows and

cracks appear due to friction, the roughness increases gradually. Therefore,

under the load of 30 MPa, the friction coefficient of UHMWPE decreases first

and then increases.

The strength of PEEK is so high that all the experimental conditions in

this study have not reached the yield strength of the material yet. The wear

surfaces are all shown as furrows or scratches along the direction of sliding

friction. Under 10 MPa load, the wear surface appears to have shallow furrows

with a small amount of plastic deformation. With the increase in load (15 and

25 MPa), the number of furrows gradually increases. At 30 MPa, the PEEK surface

shows wear morphology consisting of more obvious furrows. The main reason is

that the PEEK surface roughness peaks locally cause stress concentration on the

furrows. With the increase in load, the roughness peaks and abrasive chips are

embedded and generate a high contact stress under the action of normal loads.

Hence, the degree of mutual embedding is strengthened, which results in more

furrows. Therefore, with the increase in load, the wear rate increases

gradually, and is slightly greater than that of UHMWPE, but assumes a low

value.

|

Figure 2 Reciprocating friction coefficients under different loads: (a)-(c) are the real-time friction coefficients of PTFE, UHMWPE, and

PEEK, respectively; (d) average friction coefficient of the three engineering plastic materials. |

|

Figure 3 Material loss of PTFE in the friction process: (a) abrasive

dust; (b) transfer film. |

|

Figure 4 Wear rate curve of PTFE, UHMWPE, and PEEK with the

change of load. |

|

Figure 5 SEM photographs and EDS analysis of UHMWPE after the reciprocating friction experiment under the contact pressure of 15 MPa. |

|

Figure 6 SEM images showing the worn surfaces of PEEK, PTFE, and UHMWPE under different contact pressures. |

|

Table 3 Size Changes of PTFE and PEEK after Friction Test under Different Loads |

In this study, we have examined the effect of loads on the tribological

and wear properties of PTFE, UHMWPE, and PEEK. The conclusions are summarized

as follows:

(1) PTFE has good running performance, with the lowest average friction

coefficient and is least influenced by load. However, at the instant the

friction coefficient fluctuates under high load, the wear rate clearly

increases with the increase in load. When the load exceeds the yield strength,

the rheology of the material aggravates the wear. Therefore, the application

under high load conditions is limited.

(2) The average friction coefficient of UHMWPE is slightly higher than

that of PTFE, and the friction coefficient gradually decreases with the

increase in load. The wear rate of UHMWPE is the least affected by the load

among the three materials. Even when the load exceeds the yield strength, the

wear resistance is still good. Therefore, it is widely used under the load

condition of 30 MPa or higher.

(3) PEEK has high mechanical strength. The test conditions in this study

are not as high as its yield strength, and the wear rate gradually increases

with the increase in load, which is slightly greater than UHMWPE, but assumes a

low value. The friction coefficient decreases with the increase in load, but

maintains a high value that restricts its application in sliding friction pair

materials to some degree.

(4) The wear mechanism of the three materials evidently differs with the

load. The wear mechanism of PTFE under small loads (10 and 15 MPa) is

material folding. As the load increases, the folding increases. When the load

reaches 30 MPa, PTFE melts. Under low loads (10 and 15 MPa), the wear mechanism

of UHMWPE is furrow wear and a small amount of plastic deformation occurs. As

the load increases, the furrows gradually increase in number and become more

obvious. When the load reaches 30 MPa, the wear mechanism is furrow wear and

crack fatigue wear. The wear mechanism of PEEK is mainly furrow wear, and the

furrows increase in number and become more obvious with the increase in load.

- 1. P. Marcela, D. Bernadette, K. Thomas, and A. Vasiliki-Maria, Int. J. Surf. Sci. Eng., 11, 65 (2017).

- 2. B. B. Chen, J. Z. Wang, and F. Y. Yan, Tribol. Lett., 42, 17 (2011).

-

- 3. K. Neelima, K. L. Prav, N. L. Soni, and R. J. Patel, Wear, 342, 85 (2015).

-

- 4. J.-H. Han, H. Zhang, P.-F. Chu, A. Imani, and Z. Zhong, Compos. Sci. Technol., 114, 1 (2015).

-

- 5. M. Dolce, D. Cardone, and F. Croatto, Bull. Earthquake. Eng., 3, 75 (2005).

-

- 6. D. Sattar, R. J. Kristopher, M. Marc, W. H. Marvin, J. B. Paul, and C. Michael, J. Bridge. Eng., 24, 04019045 (2019).

-

- 7. D. L. Winstead, D. Flowers, and C. E. Pyers, Guide specifications for seismic isolation design, 3rd ed. H. S, Washington D.C, 2010.

- 8. J. P. Wang, D. X. Liu, H. B. Ke, D. G. Xiang, Y. Liu, L. Dai, and X. H. Zhang, Mech. Sci. Technol. Aerosp. Eng., 35, 646 (2016).

- 9. J. Q. Zhang, H. X. Huang, R. H. Ju, K. T. Chen, S. B. Li, W. J. Wang, and Y. S. Yan, Am. J. Surg., 213, 87 (2016).

-

- 10. G. W. Sawyer, K. D. Freudenberg, P. Bhimaraj, and L. S. Schadler, Wear, 254, 573 (2003).

-

- 11. Q. F. Wang, H. L. Wang, Y. X. Wang, and F. Y. YAN, Tribol., 35, 441 (2015).

- 12. D. I. Chukov, A. A. Stepashkin, A. V. Maksimkin, V. V. Tcherdyntsev, S. D. Kaloshkin, K. V. Kuskov, and V. I. Bugakov, Compos. Part B-Eng., 76, 79 (2015).

-

- 13. G. D. Yao, W. D. Wang, J. F. Shen, M. J. Du, and M. M. Si, Mater. Sci. Technol., 26, 56 (2018).

- 14. F. Quadrini and E. A. Squeo, Express. Polym. Lett., 1, 817 (2007).

-

- 15. Z. N. Jia and Y. L. Yang, Compos. Part B-Eng., 43, 2072 (2012).

-

- 16. V. Saikko, Proc. Inst. Eng. H., 220, 723 (2006).

-

- 17. K. A. Lauxa and C. J. Schwartz, Wear, 297, 919 (2013).

-

- 18. R. F. Vanessa, S. Jacob, P. D. Yeczain, D. B. Patrick, and A. Mátyás, Int. J. Sustain. Constr. Des., 4, (2013). DOI:10.21825/scad.v4i2.1043.

-

- 19. G. Zhang, C. Zhanga, P. Nardin, W. Y. Li, H. Liao, and C. Coddet, Tribol. Int., 41, 79 (2008).

-

- 20. H. Unal and A. Mimaroglu, J. Polym. Eng., 32, 349 (2012).

-

- 21. Z. W. Guo, S. F. Li, and K. L. He, Eng. J. Wuhan Univ., 52, 557 (2019).

- 22. Q. F. Wang, Y. X. Wang, H. L. Wang, N. Fan, and F. Y. Yan, Tribol. Int., 104, 73 (2016).

-

- 23. H. Unal and A. Mimaroglub, Mater. Design., 24, 183 (2003).

-

- 24. A. A. Pitenis, K. L. Harris, C. P. Junk, G. S. Blackman, W. G. Sawyer, and B. A. Krick, Tribol. Lett., 57, 4 (2015).

-

- 25. J. Ye, H. S. Khare, and D. L. Burris, Wear, 297, 1095 (2013).

-

- 26. K. Makinson and D. Tabor, Nature, 201, 464 (1964).

-

- 27. T. A. Blanchet and F. E. Kennedy, Wear, 153, 229 (1992).

-

- 28. K. L He, C. X. Sheng, Z. W. Guo, Y. W. Sun, and C. Q. Yuan, Lubr. Eng., 4, 54 (2019).

- 29. V. N. Aderikha, A. P. Krasnov, and A. V. Naumkin, Wear, 386-387, 63 (2017).

-

- 30. B. M. Rudresh and B. N. Kumar, Trans. Indian Inst. Met., 71, 339 (2018).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2022 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(6): 827-834

Published online Nov 25, 2020

- 10.7317/pk.2020.44.6.827

- Received on Jun 16, 2020

- Revised on Aug 11, 2020

- Accepted on Aug 12, 2020

Services

Services

Shared

Correspondence to

Correspondence to

- Duan Haitao and Li Jian

-

State Key Laboratory of Special Surface Protection Materials and Application Technology, Wuhan Research Institute of Materials Protection, Wuhan 430030, Hubei, China

- E-mail: duanhaitao2007@163.com, lijianwuhan@163.net

- ORCID:

0000-0002-6892-4897, 0000-0002-9228-6469

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.