- Mechanical and Damping Properties of Graphene-Modified Polyurethane-Epoxy Composites for Structures

Civil Engineering, Nanjing Forestry University, Nanjing 210037, China

*Civil Engineering, Southeast University, Nanjing 211189, China- Graphene으로 개질된 폴리우레탄-에폭시 복합체의 기계적 물성과 Damping 특성

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

Polyurethane (PU) has received extensive attention in structural engineering due to its excellent mechanical properties and damping properties. In this research, graphene-modified PU-epoxy composites are prepared for the application in structural engineering. The mechanical properties and damping properties of the composites with different contents of graphene are investigated. The damping properties of the composites were also investigated by performing dynamic mechanical analysis (DMA). The results showed that with the increase of graphene content, the tear strength of the composites decreased from 52 to 39 MPa. Due to the enhancement of appropriate amount of graphene, the tensile strength and elongation at break increase to the maximum value, being 16 MPa and 675%, respectively. And DMA tests showed that the damping properties reach the optimal values when the graphene content is 0.2%. The large damping temperature range (ΔT0.5) is 33 °C, from -2.9 to 30.1 °C. The peak of loss factor (ηmax) is 0.92 and the integral area (TA) is 36 °C, much higher than those of the pure PU-epoxy composites. In addition, scanning electron microscopy (SEM) results show that agglomeration appears with higher graphene content.

Graphene-modified polyurethane-epoxy composites are prepared for the application in structural engineering. The results showed that the damping properties reach the optimal values when the graphene content is 0.2%. The large damping temperature range (ΔT0.5) is 33 °C, from -2.9 to 30.1 °C. The peak of loss factor (ηmax) is 0.92 and the integral area (TA) is 36 °C, much higher than those of the pure PU-epoxy composites.

Keywords: polyurethane, graphene, structural engineering, mechanical properties, damping properties.

Information is available regarding the performance objectives of graphene-modified polyurethane-epoxy composites. The materials are available via the Internet at http://journal.polymer-korea.or.kr.

PK_2021_045_04_483_Supporting_Information_template.pdf (431 kb)

Supplementary Information

Currently, there is rare research on the application of polyurethane (PU) materials to structural seismic isolation and shock absorption. PU materials are widely used in reducing the equipment vibration with little account taken of mechanical and damping properties in large deformation and extreme loads.1-3

One of the dominating problems that prevent PU from being widely used in building field is their insufficient mechanical properties. The strength of PU material is not high enough and its deformation capability is low.4,5 Previous research6-8 has shown that graphene can improve the mechanical properties of composites. Bu6 investigated the reasons why graphene can improve the mechanical properties of rubber composites, including fold structures, the large specific surface area, high van der Waals forces and excellent mechanical properties. Li7 found that the tensile strength and bending strength of graphene/cyanate ester composites increased by 20.6% and 41.7% respectively, compared to pure cyanate ester. Similarly, Yang8 also found that graphene can improve the mechanical properties of composites, especially the tensile strength and the impact strength. In summary, graphene is an ideal strength modified material for PU. However, to improve the damping ability and temperature dependence of PU, it still needs to be blended with some other chemicals, while it is the main factor leading to the significant reduction in the mechanical properties.

Another significant problem is that although PU has better damping performance than rubber,9 it can hardly meet the requirements, especially the high loss factor in wide temperature range, for resisting strong earthquake or wind vibration. It has been found that graphene can effectively enhance the damping properties of PU.10-14 The unique two-dimensional lamellar structure of graphene gives it a large specific surface area, and its largest value can reach 2630 m2/g.10 Therefore, the composites have more interfaces through graphene modification. Further, the relative slip and deformation between the interfaces result in more energy dissipation under external loads.11,12 On a microscopic level, graphene sheets exhibit soft morphology, which can easily cause obvious bending and folding phenomenon.13 That is, graphene is prone to tensile deformation under external loads, thus dissipating the partial mechanical energy. Besides, Agarwal et al.14 analyzed the graphene sheets by dynamic mechanical analysis (DMA) tests. The results showed that graphene has excellent viscoelastic damping properties.

Moreover, the temperature sensitivity of damping performances is rarely considered in the existing research. It is known that damping materials should possess high loss factors in a wide temperature range under service temperature either for dampers or for isolators. So, the temperature sensitivity is a quite significant factor in structural engineering. Overall, when apply PU damping materials to structural engineering, multi performances should be achieved simultaneously, such as mechanical properties, damping properties and the temperature sensitivity. In this study, PU/epoxy interpenetrating polymer network (EP IPN) was modified by graphene to prepare the composites with excellent performances to be used in building structures. In order to meet the requirements for high strength and large deformation, mechanical properties, damping properties and the temperature sensitivity should be improved. For mechanical properties, mechanical experiments were conducted to investigate the hardness, tensile strength, elongation at break, compression set and tear strength of the composites. For damping properties and temperature sensitivity, DMA tests were conducted to investigate the loss factor (tanδ), glass transition temperatures (Tg), the large damping temperature range (∆T0.5) and the integral area (TA).

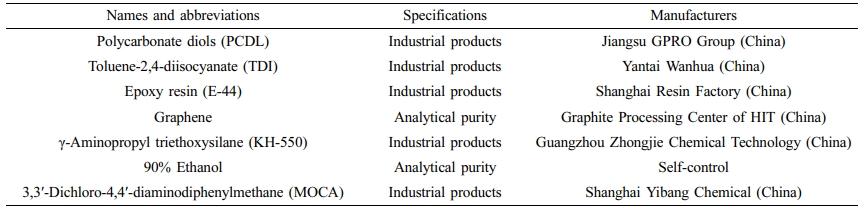

Raw Materials. The main raw materials are listed in Table 1. It should be mentioned that the diameter of graphene is 6-11 µm, and the specific surface area is 146 m2 g-1.

Specimen Preparation. γ-Aminopropyl triethoxysilane (KH-550) was used to modify graphene for preventing agglomeration and improving its compatibility with PU. Firstly, 90 wt% ethanol was prepared by mixing 80 g ethanol with 20 g KH-550 and stirred for 10 min at 250 r min-1. Then, 1 g graphene was added into this solution. After ultrasonic dispersing for 1 h, it was stirred for 2 h and was filtered with ethanol for three times. Finally, the filter material was placed in an oven at 80 °C for 12 h, taken out and sealed.

In mass fraction, polycarbonate diols (PCDL) with 40 parts was heated to 100 °C and dried for 1 h. Then, NCO-terminated PU prepolymer was obtained by adding toluene-2,4-diisocyanate (TDI) with 10 parts in the PCDL. And the prepolymer was stirred for 90 min under the protection of N2.

Dried epoxy with 40 parts was mixed into PU prepolymer with 60 parts and stirred for 10 min at 80 °C. Then, graphene (0, 0.1, 0.2, 0.3, 0.4 phr according to Table 2) was added. After stirring the mixture and exhausting gas for 1 hour in a vacuum, 3,3′-dichloro-4,4′-diaminodiphenylmethane (MOCA) with 14 parts was added. The mixture which was stirred for 5 min was casted in the mold which has been preheated at 80 °C. And the specimens were solidified after vulcanizing for 1 h on a 120 °C flat vulcanizing machine (Huayuan Machinery, China, XLB-D). Finally, the specimens were prepared by continuous curing for 10 hours in an oven at 100 °C.

Test Schemes. The hardness tests of PU damping materials were carried out by Shore Hardness Tester (Shanghai Liuling, China LX-A), referring to GB/T 531.1-2008 “Rubber, vulcanized or thermoplastic—Determination of indentation hardness—Part 1: Durometer method (Shore hardness)”.

Tensile strength, elongation at break and tear strength were measured on a universal material experiment machine (SHIMADZU, Japan, AG-50kNG) with a strain rate of 500 mm min-1. According to GB/T 528-2009 “Rubber, vulcanized or thermoplastic—Determination of tensile stress-strain properties” and GB/T 529-2008 “Rubber, vulcanized or thermoplastic—Determination of tear strength”, the specimens with the thickness of 2 mm were dumbbell type 2 and angle type respectively.

Compression sets of the specimens were tested by desktop thickness gauge (Jiangdu Mingzhu, China, MZ-4030) according to GB/T 7759.1-2015 “Rubber, vulcanized or thermoplastic—Determination of Compression set—Part 1: At ambient or elevated temperatures”.

The dynamic performances were obtained by dynamic mechanical analyzer (PerkinElmer, USA, DMA 8000). The tests were carried at the frequency of 3.5 Hz with the temperature ranging from -50 °C to +60 °C, as well as the heating rate being 3 °C/min. According to seismic behavior of dampers or isolators, the shear mode was used. Referring to GB/T 9870.1-2006 “Rubber, vulcanized or thermoplastic—Determination of dynamic properties—Part 1: General guidance”, the dimension of the specimens was 50 mm×8 mm×2 mm.

The morphologies of the specimens were observed by a scanning electron microscopy (Hitachi Electronics, Japan, JSM-IT100) with the scanning voltage of 20 kV and 1000 magnification. The specimens were treated by liquid nitrogen embrittlement and coated with gold before scanning.

|

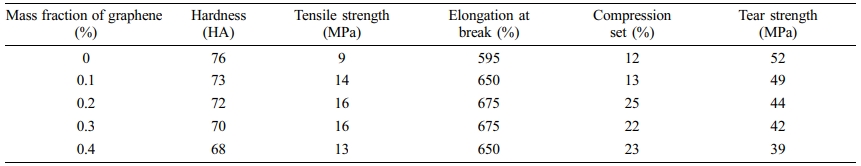

Table 2 Physical and Mechanical Properties of Composites Filled with Different Graphene Contents |

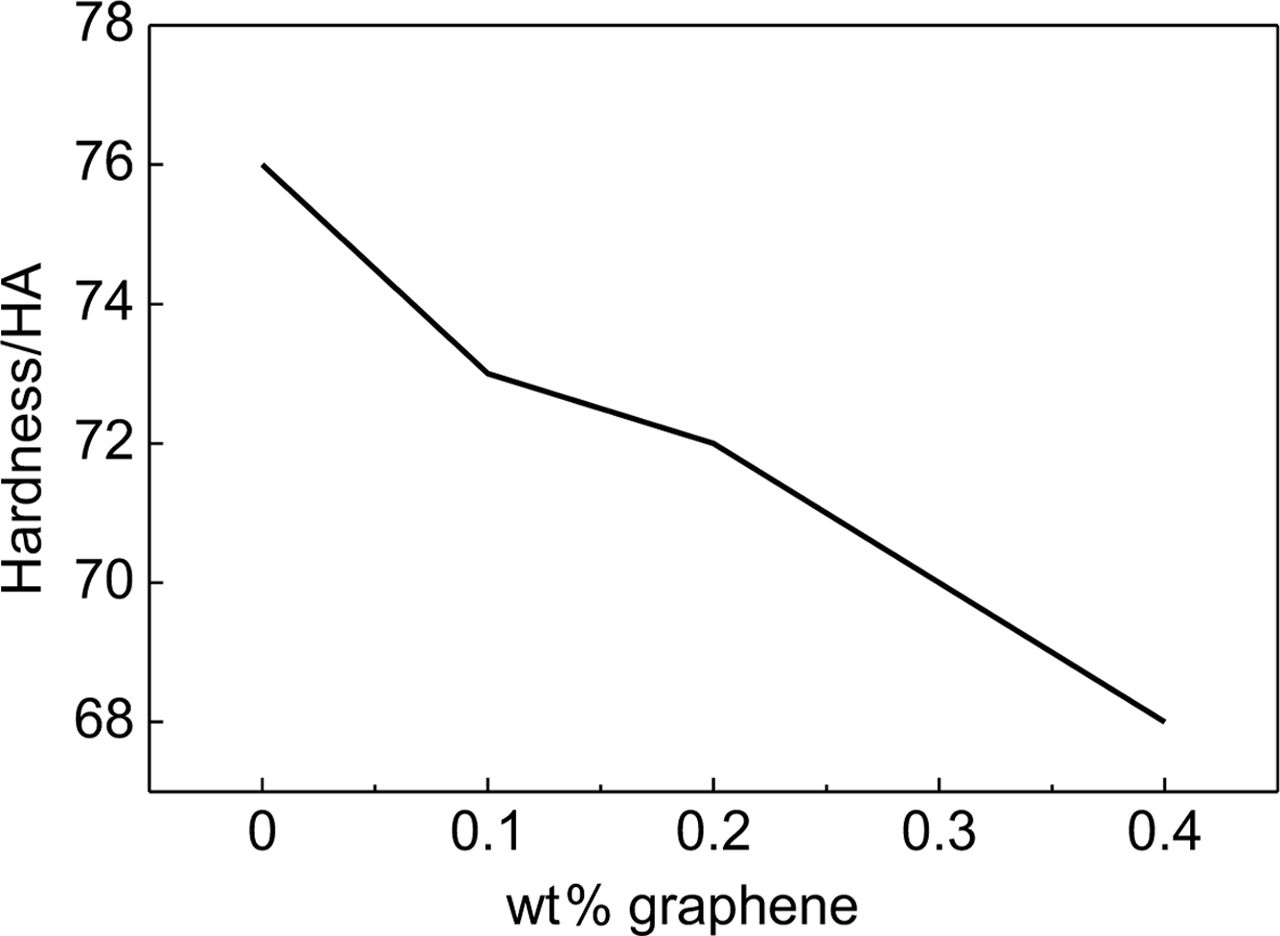

Physical and Mechanical Properties. Physical and mech- anical properties of the composites with different graphene contents are listed in Table 2. And the variation of the hardness of composites as a function of graphene content is shown in Figure 1.

It is obviously that the shore hardness of the composites gradually decreased with increasing graphene content. When the graphene weight content was 0.4%, Shore hardness was down to the minimum value of 68 HA. It is considered that graphene is a new lubricating material,15 and the lubricity can be used to explain the decline of Shore hardness. According to the principle of structural dynamics, the lower the stiffness of isolators is, the higher the isolation efficiency is. The rigidity of the isolator is related to the hardness of composites. Therefore, to a certain extent, it can be predicted that the higher the graphene content is, the better the isolation efficiency is.

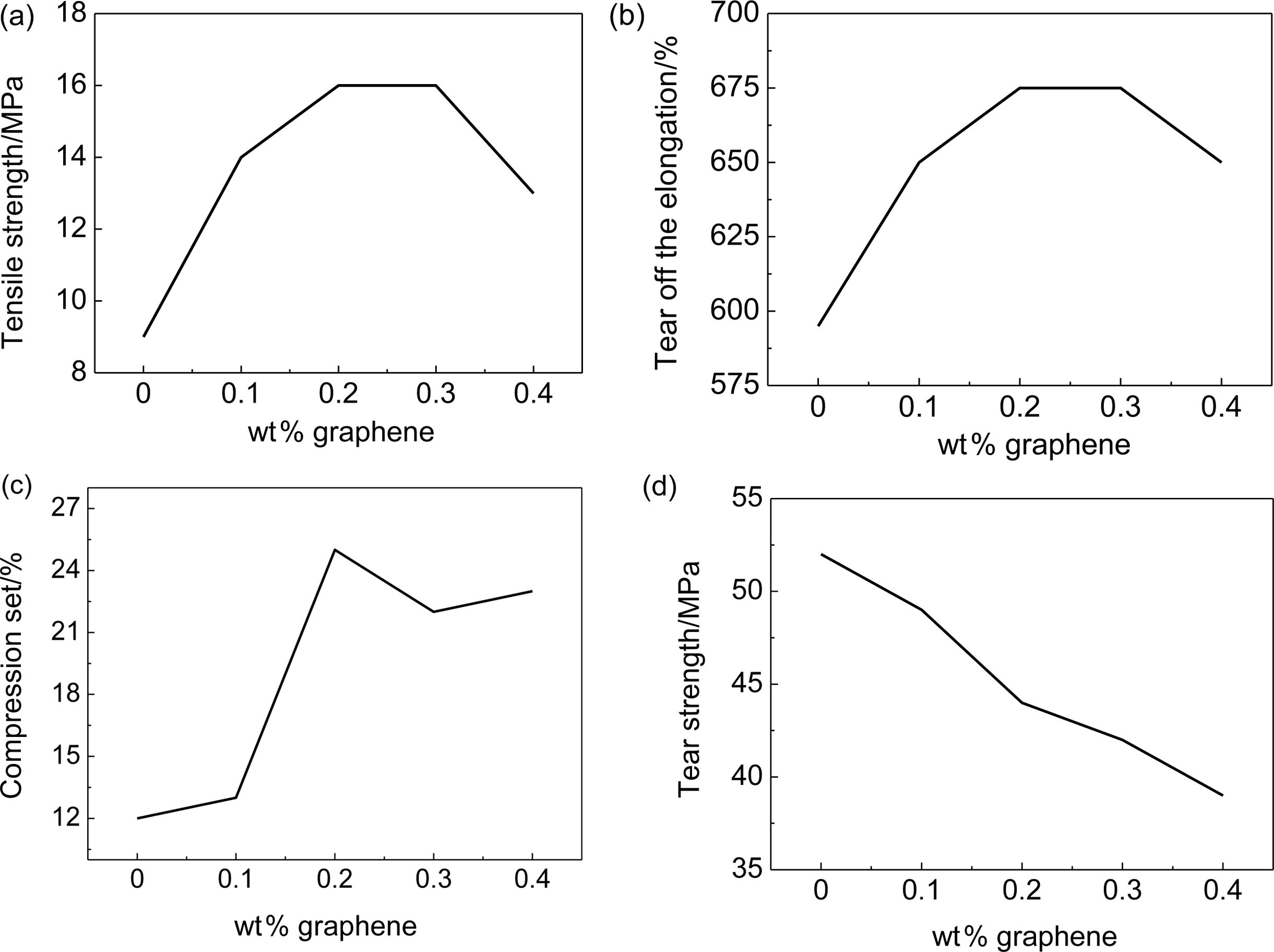

The tensile strength, elongation at break, compression set and tear strength of graphene-modified PU/EP IPN are illustrated in Figure 2, as a function of graphene content.

As shown in Figure 2(a) and 2(b), the tensile strength and elongation at break of the composites increased to the maximum value with increasing graphene content and then decreased. The tensile strength and the elongation at break of the matrix material without graphene was 9 MPa and 595% respectively, which both were the minimum values. When the content of graphene was 0.2% and 0.3%, the tensile strength reached the maximum value of 16 MPa, which increased by 77.8%. Meanwhile, elongation at break was 675%, increased by 13.4%. Residual functional groups on graphene react with isocyanate group in PU matrix to form covalent bond π-π, which can be used to explain the increasing of tensile strength and elongation at break. It is destroyed and the chain is released under the external force, which improves the toughness and ductility of the composites. When a structure is subjected to strong earthquake or strong wind, huge internal forces will be produced in it. And then dampers or isolation bearings will suffer large deformation. Therefore, the higher the tensile strength and elongation at break of the damping material is, the greater the earthquake or wind it can resist is. However, they both decreased due to agglomeration when graphene weight content was 0.4%. It can be observed from Figure 5 of the scanning electron microscope.

When the content of graphene was not more than 0.2%, the compression set of the composites was raised quickly, and then the index was no more changed evidently when the amount of graphene was increased, as shown in Figure 2(c). Decreasing curve of the tear strength from 52 to 39 MPa was obtained in Figure 2(d). However, compared with rubber damping materials,16 the minimum value is more than 1.5 times of rubber’s tear strength. In terms of tear strength, since rubber is widely used in structural damping and isolation analogically, the composites are suitable as a matter of course. Considering that the composites are not compressed when used in dampers of building structures, compression set has little effect on their seismic performance. And the isolators do not need excellent compression resilience because they are subjected to constant vertical compression in their service period. As is known to all, for isolation bearings and dampers, the resistance performance to horizontal shear is more important. That is, their performance under the ultimate stress state is determined by internal tensile strength and elongation at break with little account taken of tear strength.

Above all, tear strength decreases with increasing graphene content, however, the tensile strength and elongation at break of the composites tends to increase and then decrease. Obviously, the content of graphene should be considered comprehensively according to the performance requirements in Supporting information. Therefore, when the content of graphene is 0.2%, the physical and mechanical properties of the composites are most suitable for building structures.

Damping Properties. The anelasticity of PU materials is mainly affected by its internal structure and chain segments. To a large degree, the motions of the molecular chains vary greatly by chain segments according to the external temperature or the frequency of load. Thereby, the damping properties change accordingly. Therefore, the dynamic mechanical performances of frequency-dependence and temperature-dependence were focused.

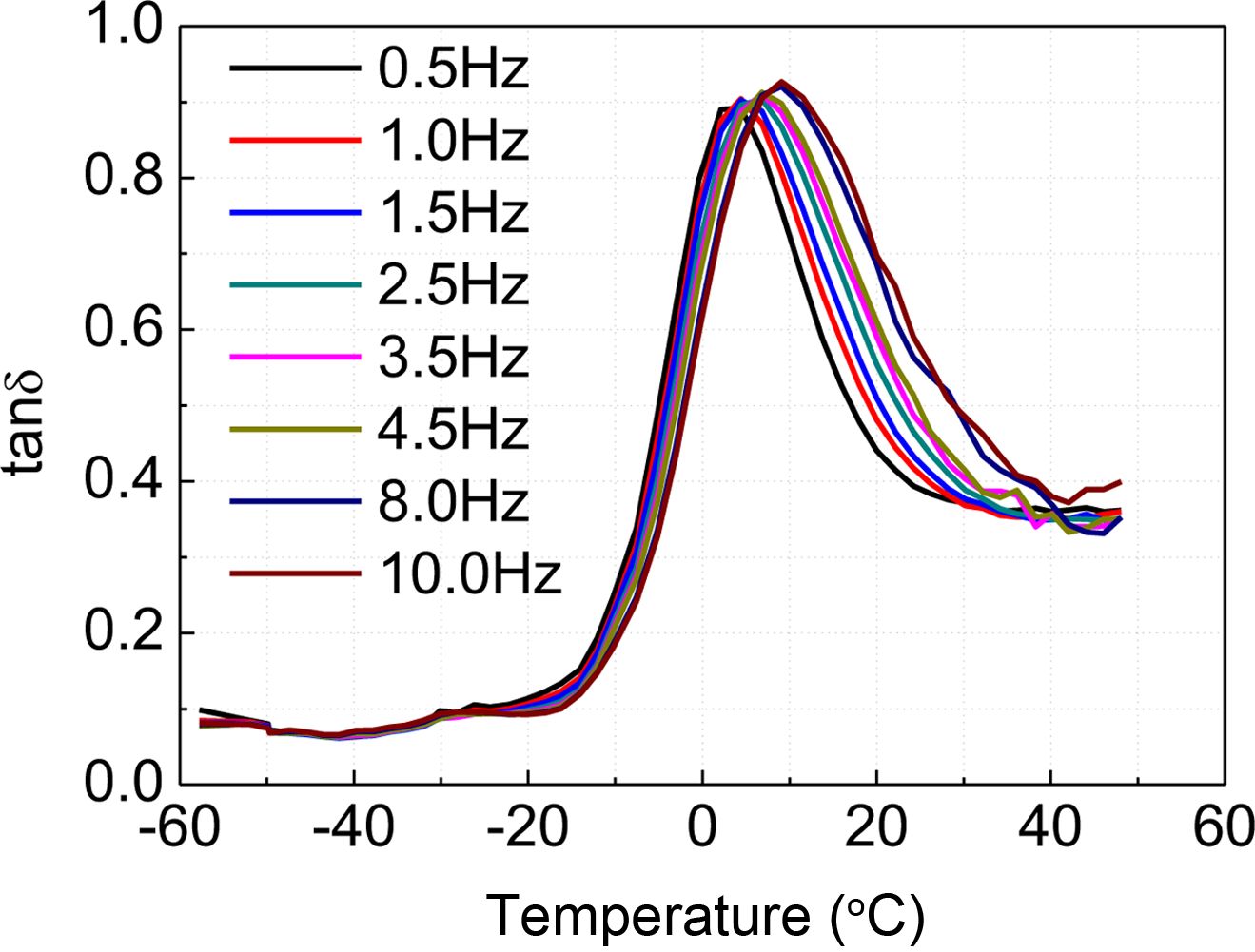

Frequency Dependency: The relationship between frequencies and dynamic mechanical properties is shown in Figure 3. It can be found that with the increase of frequency between 0.5 Hz and 10 Hz, Tg shifted to higher values, the peak of loss factor (ηmax) improved and the large damping temperature range (∆T0.5) became wider significantly. Thus, the damping properties of the composites were improved with the increase of frequency. As shown, the curves were concentrated below the temperature of Tg, which implied that the frequency had little effect on it. The lower the temperature was, the less the frequency correlation was. When the temperature was higher than Tg, the influence of frequency variation was greater and the curves were more dispersed. So with the increase of temperature, the PU damping materials tend to show more obvious frequency variability. And the hysteresis phenomenon is more evident with the increasing of frequence. Therefore, in the frequency range of 0.5 to 10 Hz, the frequency has apparent impact on the dynamic mechanical properties of building materials when the temperature is higher than Tg.

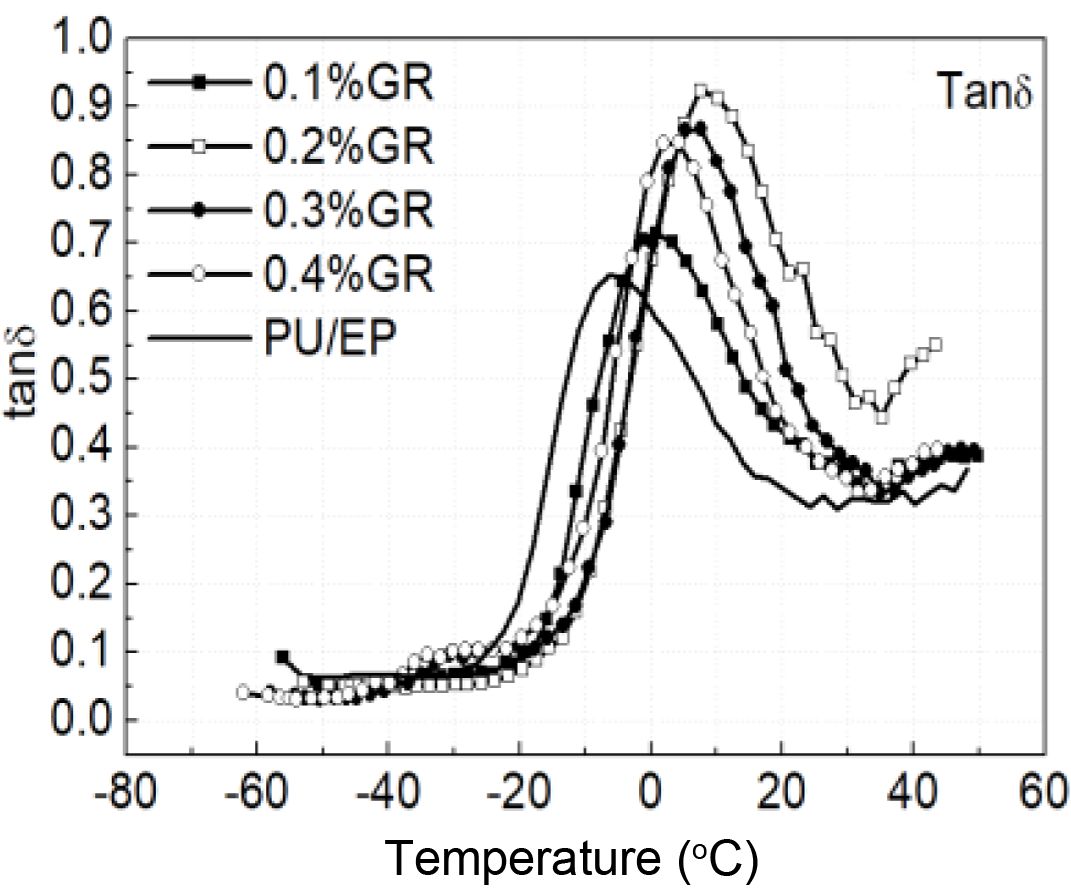

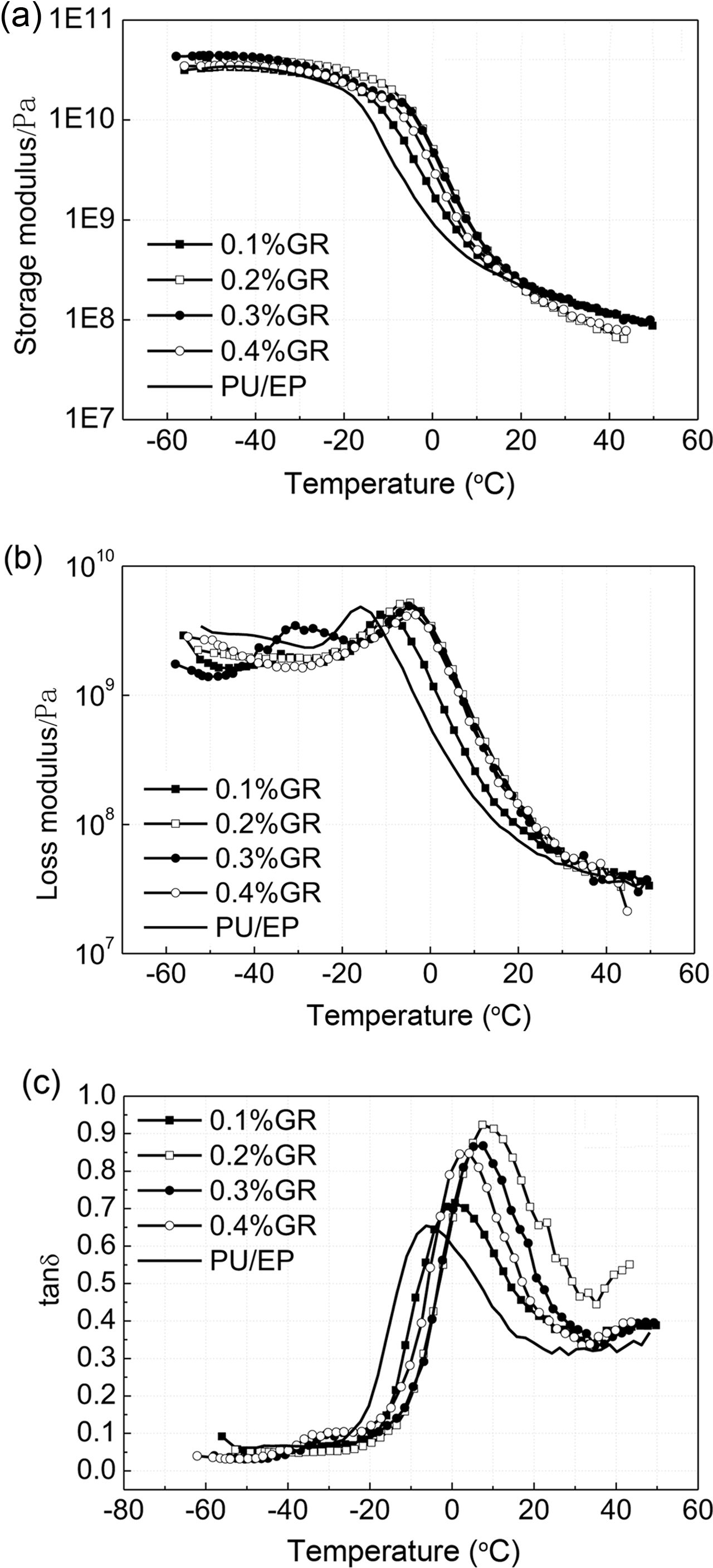

Temperature Dependency: The relationship between temperature and dynamic mechanical properties of composites filled with different graphene contents is shown in Figure 4. It can be seen that the content of graphene has a little effect on the storage modulus and loss modulus of the composites from Figure 4(a) and 4(b). δ is very small below the temperature of -20 °C, for the fact that chain segments move slowly, almost no deformation under the action of external loads. Therefore, it can be seen that tanδ was small at that temperature range in Figure 4(c). Obviously, the curves of tanδ were relatively scattered in the working temperature range (0-30 °C) in construction engineering. Because the chain segments can be fully stretched and the strain can lag with a large phase difference behind the stress, resulting in a large value of tanδ. That is, graphene has evident influence on tanδ on this condition. As shown in Figure 4(c), Tg of the composites shifted to higher temperature with the increase of graphene contents, which is more beneficial for application to the building structures.

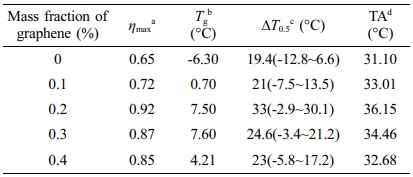

The indexes of dynamic mechanical properties of the composites filled with different graphene contents are listed in Table 3. As shown, ηmax of the matrix material was 0.65, the corresponding glass transition temperature was -6.3 °C, and ∆T0.5 was 19.4 °C (-12.8-6.6 °C). So the matrix material is not suitable for engineering structures. Obviously, the damping properties of the composites are improved by adding graphene. When graphene content was 0.2%, ηmax reached the maximum value of 0.92, compared with the matrix material, the value increased by 41.5%. Tg shifted to higher temperature by 13.8 °C and ∆T0.5 broadened by 13.6 °C. Besides, the value of TA increased from 31.1 to 36.15 °C. The results show that graphene not only contribute to the energy consumption of the composites, but also significantly improve the applicable temperature and widen the large damping temperature range. However, when the graphene content increased further, the damping properties of the composites showed a gradual downward trend. Compared with the maximum values, ηmax decreased by 7.6%, Tg shifted to lower temperature by 3.29 °C, ∆T0.5 decreased by 30.3% and TA value decreased by 3.47 °C. These phenomena are mainly caused by the special two-dimensional structure of graphene consisting of carbon atoms. Relative motions and frictions on the molecular level with large specific surface area occur when composites are subjected to external forces, resulting in partial mechanical dissipation. In addition, under the action of external loads, graphene layers are prone to move relatively to PU/EP for the weak interface forces. So partial mechanical energy dissipated by additional sliding. However, with graphene amount increasing, agglomeration (Figure 5(d)) happened which leading to decreasing of compatibility between graphene and PU materials, resulting in a negative impact on the damping properties of the composites. When the negative effect was greater than the positive effect of graphene on the damping performance of composites, the dynamic mechanical property decreased, which can be seen from Table 3.

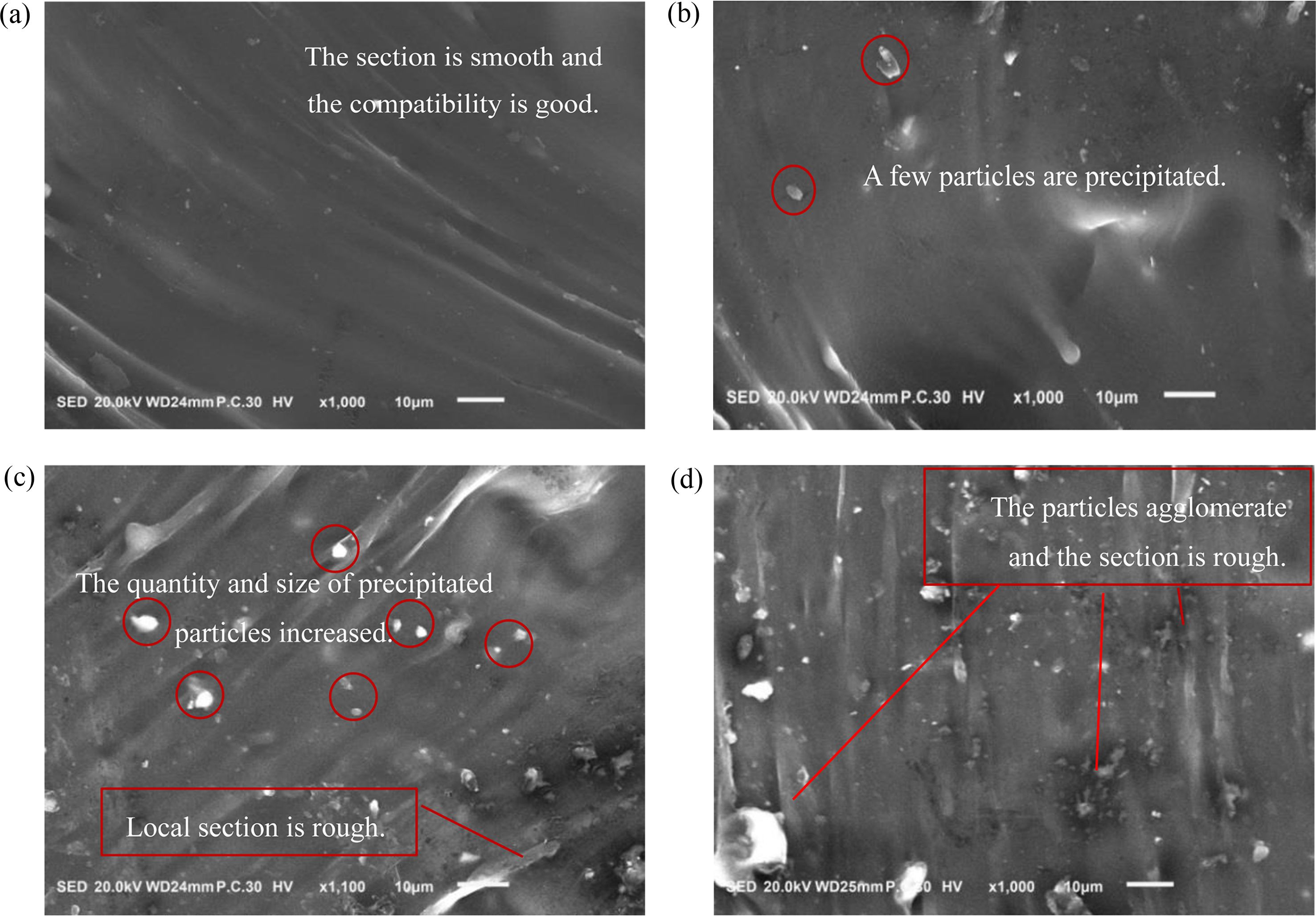

SEM Observation. Scanning electron microscope (SEM) photographs of the damping material filled with different graphene contents is shown in Figure 5. It can be clearly seen that with the increase of graphene contents, more and more particles were precipitated from the cross section of the composites, and the cross sections were getting rougher and rougher. When the content of graphene increased from 0.1% to 0.2%, the precipitated particles increased obviously, but the section was still smooth. When the graphene contents reached 0.3%, the precipitated particles became larger and the cross section was rough. The compatibility and dispersibility both decreased when PU materials filled with excessive graphene, which was also the reason for the decrease of tensile properties and damping properties of composites, as mentioned before.

|

Figure 1 Hardness of damping materials with different graphene addition |

|

Figure 2 Physical and mechanical properties of composites with different graphene contents: (a) tensile strength; (b) tear off the elongation; (c) compression set; (d) tear strength. |

|

Figure 5 SEM micrographs of composites with graphene: (a) 0.1% mass fraction of graphene addition; (b) 0.2% mass fraction of graphene addition; (c) 0.3% mass fraction of graphene addition; (d) 0.4% mass fraction of graphene addition. |

|

Figure 3 Dynamic mechanical properties of 0.4% GR PU/EP under different frequencies. |

|

Figure 4 Dynamic mechanical properties under different graphene contents: (a) storage modulus; (b) loss modulus; (c) tanδ |

|

Table 3 Indicators Under Different Graphene Addition |

a ηmax is the maximum value of tanδ-T. b Tg is the temperature corresponding to ηmax. c ∆T0.5 is the large damping temperature range in which loss factor is larger than 0.5. d TA is the integral area of tanδ-T. |

(1) The mechanical properties and damping properties of the composites can be significantly improved by a little amount of graphene.

(2) When the mass fraction of graphene was 0.2% or 0.3%, the physical and mechanical properties of the composites were the best. Tensile strength and elongation at break were 16 MPa and 680% respectively. The compression set was 22% and tear strength reached 39 MPa.

(3) When the mass fraction of graphene was 0.2%, the highest damping properties of the composites were obtained. The peak of loss factor ηmax was 0.92, increasing by 27.8% compared with the matrix material. The large damping temperature range ∆T0.5 was 33 °C, and the TA value reached 36.15 °C.

(4) It was shown by SEM analysis that with the increase of graphene contents, agglomeration intensified. With the increase of graphene contents, more and more particles were precipitated from the cross section of the composites, and the cross sections were getting rougher and rougher.

- 1. Sun, Z. H.; Guo, Y. P.; Li, B. E.; Tan, T. Z.; Zhao, Y. ZnO/carbon Nanotube/reduced Graphene Oxide Composite Film as an Effective Interlayer for Lithium/sulfur Batteries. Solid State Sci. 2019, 95, 105924.

-

- 2. Hung, P. Y.; Kintak Lau; Qiao, K.; Fox, B.; Hameed, N. Property enhancement of CFRP composites with different graphene oxide employment methods at a cryogenic temperature. Composites Part A 2019, 120, 56-63.

-

- 3. Chan, K. C.; Tso, C. Y.; Hussain, A.; Christopher, Y. H. C. A Theoretical Model for the Effective Thermal Conductivity of Graphene Coated Metal Foams. Appl. Therm. Eng. 2019, 161, 114112.

-

- 4. Yin, J.; Zhang, W. Electromagnetic Interference Shielding Performance-nanosheet/polyethylene Composite Films. Acta Materiae Compositae Sinica 2019, 36, 293-303.

- 5. Kim, S. Y.; Song, Y. I.; Wee, J. H.; Kim, C. H.; Ahn, B. W.; Lee, J. W.; Shu, S. J.; Terrones, M.; Kim, Y. A.; Yang, C. M. Few-layer Graphene Coated Current Collector for Safe and Powerful Lithium Ion Battery. Carbon 2019, 153, 495-503.

-

- 6. Jin, G.; Zhang, D.; Liu, M. Y.; Cui, X. F.; Liu, E.; Song, Q. L.; Yuan, C. F.; Wen, X.; Fang, Y. C. Microstructure, Deposition Mechanism and Tribological Performance of Graphene Oxide Reinforced Fe Composite Coatings by Electro-brush Plating Technique. J. Alloys Compd. 2019, 801, 40-48.

-

- 7. Tang, Y. P.; Xu, Q.; Tang, R. Z.; Zhang, F. Preparation and Applications of Two Dimensional Carbon Materials. Carbon 2016, 110, 518-520.

-

- 8. Jiang, Y.; Yan, S. L.; Chen, Y. P. Li, S. F. Preparation, Characterization, and Properties of Silanized Graphene Oxide Reinforced Bio Based Benzoxazine-bismaleimide Resin Composites. J. Adhes. Sci. Technol.2019, 33, 1974-1988.

-

- 9. Du, W. N.; Jin, Y.; Lai, S. Q.; Shi, L. J.; Shen, Y. C.; Pan, J. Z. Urethane-silica Functionalized Graphene Oxide for Enhancing Mechanical Property and Fire Safety of Waterborne Polyurethane Composites. Appl. Surf. Sci. 2019, 492, 298-308.

-

- 10. He, X. L.; Yu, Y. F.; Chen, Q.; Shi, X.; Lin, S. Recent Advances in Graphene-based Composite Materials. Mater. Rev. 2013, 27, 22-28.

- 11. Idowu, A.; Nautiyal, P.; Fontoura, L.; Loganathan, A.; Boesl, B.; Agarwal, A. Multi‐scale Damping of Graphene Foam‐based Polyurethane Composites Synthesized by Electrostatic Spraying. Polym. Compos. 2019, 40, 1862-1870.

-

- 12. Xu, J. H.; Li, A. Q.; Su, Y.; Zhuang, J. Z.; Huang, G. Y.; Luo, C. Y. Dynamic Damping Mechanical Analysis of Viscolastic Damping Material Mixed Norsorex by Ring-opening Metathesis Polymerization. Polym. Mater. Sci. Eng. 2015, 31, 51-56.

- 13. Yang, B.; Chen, J.; Su, L. F.; Miao, J. B.; Chen, P.; Qian, J. S.; Xia, R.; Shi, Y. Melt Crystallization and Thermal Properties of Graphene Platelets (GNPs) Modified Recycled Polyethylene Terephthalate (RPET) Composites: The filler network analysis. Polym. Test. 2019, 77, 105869.

-

- 14. Debrupa, L.; Santanu, D.; Wonbong, C.; Agarwal, A. Unfolding the Damping Behavior of Multilayer Graphene Membrane in the Low-frequency Regime. ACS Nano 2012, 6, 3992-4000.

-

- 15. Chen, S. B.; Wang, Q. H.; Wang, T. M. Damping, Thermal, and Mechanical Properties of Carbon Nanotubes Modified Castor Oil-based Polyurethane/epoxy Interpenetrating Polymer Network Composites. Mater. Des. 2012, 38, 47-52.

-

- 16. Wang, Y. Q.; Liao, L. S.; Lin, H. T.; Zhang, F. Q.; Zhong, J. P.; Xu, K.; Peng, Z. Damping Properties of Natural Rubber/Epoxidized Natural Rubber Composites with Different Fillers. Adv. Eng. Res. 2018, 120, 772-775.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2021; 45(4): 483-490

Published online Jul 25, 2021

- 10.7317/pk.2021.45.4.483

- Received on Sep 11, 2020

- Revised on Mar 14, 2021

- Accepted on Apr 12, 2021

Services

Services

- Full Text PDF

- Abstract

- ToC

- Supporting Information

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Yi Su, Ting Li

-

Civil Engineering, Southeast University, Nanjing 211189, China

- E-mail: 230208106@seu.edu.cn

- ORCID:

0000-0002-9801-3314

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.