- Enhancement of the Acoustic Performance of Polyurethane Composite Foams Including Cyclopentane and Melamine Filler

Department of Chemical Engineering & Center for Innovative Chemical Processes (Institute of Engineering), University of Seoul, 163 Seoulsiripdae-ro, Dongdaemun-gu, Seoul 02504, Korea

- 싸이클로펜테인과 멜라민 필러를 포함한 폴리우레탄 폼의 흡음성능 향상

서울시립대학교 화학공학과

Reproduction, stored in a retrieval system, or transmitted in any form of any part of this publication is permitted only by written permission from the Polymer Society of Korea.

Polyurethane (PU) foams are widely used as sound-absorbing materials in automobile interiors because of their light weight and shaping ability. In this study, the morphology, sound absorption coefficient, and thermomechanical properties of PU foams with cyclopentane as a co-blowing agent and melamine particles as fillers were analyzed. The addition of cyclopentane and melamine particles affected the viscosity of the polyol system and the interfacial compatibility between the fillers and the PU matrix, resulting in cavity and pore structures. However, when excessive amounts of cyclopentane were added, the viscosity decreased significantly, which weakened the cavity walls and led to a decrease in sound absorption performance. It was further confirmed that the sound absorption performance decreased owing to particle agglomeration when excess melamine particles were added. Through a morphological analysis, the cavity/pore size and open porosity were found to be strongly related to the sound absorption coefficient.

폴리우레탄(PU) 폼은 가볍고 성형이 용이하여 자동차 내부의 흡음재와 시트재로 널리 사용된다. 본 연구에서는 보조 발포제로 싸이클로펜테인을 사용하고, 필러로 멜라민 입자를 첨가한 PU 폼의 형태학적 구조, 흡음계수, 열기계적 특성을 분석하였다. 싸이클로펜테인과 멜라민 입자의 첨가는 폴리올 시스템의 점도와 필러와 폴리우레탄 메트릭스(PU matrix) 간의 계면 상호작용에 영향을 주어 공동(cavity) 및 기공(pore) 구조 형성에 영향을 주었다. 하지만 싸이클로펜테인을 과도하게 첨가할 경우 점도가 크게 감소하여 공동 벽이 약화되었고, 이로 인해 흡음성능이 저하되었다. 또한 멜라민 입자를 과량 첨가했을 때 입자 응집이 발생하여 흡음 성능이 감소하는 것도 확인되었다. 형태학 분석을 통해 공동/기공 크기 및 개방 기공률(open porosity)이 흡음계수와 밀접한 관련이 있음을 확인했다.

Polyurethane (PU) foams are widely used as sound-absorbing materials in automobile interiors because of their light weight and shaping ability. The inclusion of cyclopentane and melamine particles enhanced the sound absorption performance of the PU foams. Various analyses (morphology, NCO conversion, thermomechanical property, etc) were conducted to investigate the association with acoustic properties.

Keywords: melamine particle, morphology, NCO conversion, polyurethane, cyclopentane.

This study was supported by the Basic Study and Interdisciplinary R&D Foundation Fund of the University of Seoul (2025) for Jung Hyeun Kim. This research was also supported by the Post-Plastic Specialized Graduate Program through the Korea Environmental Industry & Technology Institute (KEITI), funded by the Ministry of Environment (MOE) for Insung Ree.

The authors declare that there is no conflict of interest.

In the modern automobile industry, the demand for reducing noise pollution in vehicle interiors to create a comfortable environment for passengers is increasing continuously. Noise is becoming an important factor in the comfort of passengers in cars. Noise affects several aspects of human functioning, such as the psychological state of passengers and work performance, and significantly impacts the overall riding experience and satisfaction.1 Passengers in cars experience two main types of noise: airborne noise (500-8000 Hz) caused by collisions between air molecules and the car, and structure-borne noise (30-500 Hz) caused by mechanical vibrations.2 Therefore, various methods such as impedance mismatch or vibration isolation are considered in a broad sense to control airborne and structure-borne noise.3 Therefore, it is important to manufacture materials that can induce viscous airflow and friction against pore walls to improve sound absorption characteristics.4

Currently, various attempts are being made to improve the sound-absorption characteristics of PU composite foams. Methods for controlling the main components of the polyol system have also been developed, such as changing the types of polyols,5,6 catalysts,7,8 isocyanates,9,10 blowing agents,8 and cross-linkers.11 These studies are being conducted in the modern automobile industry to create a comfortable interior environment for passengers, along with the positive experiences of passengers. Controlling the internal morphology is becoming important in terms of sound absorption characteristics. The combined use of chemical and physical blowing agents acts as a mechanism to reduce the internal cell size,12,13 and fillers are also effective additives that can change the internal morphology.14,15 These materials can be used to modulate the viscosity, strength, and viscoelasticity of the PU composite foams. Additionally, when fillers are used as additives, the interfacial interaction between the PU matrix and fillers becomes important. Various methods are studied to achieve effective interactions, such as the use of silane coupling agents,16 oleic acid,17 dispersants,18 and sonication.19 The interfacial interaction between the PU matrix and fillers is an important parameter for determining foam properties. Therefore, determining the optimal content of the materials used will play an important role in producing PU foam with excellent sound absorption characteristics, which is currently being studied.

In this study, we aim to improve the sound absorption properties of PU composite foams using cyclopentane and melamine particles. First, we investigated the optimal cyclopentane content for use as a co-blowing agent. Second, we added melamine particles to the optimal cyclopentane content to improve sound absorption. A dispersant was used to reduce the agglomeration of the melamine particles, reduce the viscosity of the polyol system, and increase its dispersion stability of the polyol system. The viscosity of the polyol system reduced by cyclopentane and dispersant was analyzed using Fourier transform infrared (FTIR) spectroscopy. The morphology changed with the use of cyclopentane and melamine particles was analyzed using scanning electron microscopy (SEM). With an aid of the model calculation for the sound absorption coefficient, the optimal contents of the cyclopentane and melamine particles were determined for the best sound absorption performance through impedance tube analyses. The damping properties of the PU composite foams were also measured to understand the close relationship with the sound absorption property using dynamic mechanical analysis (DMA).

Materials. Polyether polyol (PPG-6000, OH-value: 28±2, Mw: 6000 g/mol, fav: 3, Kumho Petrochemical, Korea) and the isocyanate (KW 5029/1C-B, %NCO of 35±0.5, 290 cps at 25 ℃, 78 wt% of 4,4'-methylene bis(phenyl isocyanate), 5 wt% of benzene 1,1 methylene bis(4-isocyanato), and 17 wt% of toluene diisocyanate, BASF, Germany) were used to synthesize the PU composite foams. DABCO 33LV (67 wt% dipropylene glycol and 33 wt% triethylenediamine, Air Products and Chemicals, USA) was used as a gelling catalyst. Additionally, DABCO BL17 (78 wt% bis(dimethylaminoethyl)-etherformate dipropylene glycol solution, Air Products and Chemicals, USA) was used as a blowing catalyst. Diethanolamine (DEA, Mw: 105.14 g/mol, Sigma-Aldrich, USA) was used as the crosslinker. Deionized water was used as the chemical blowing agent. Momentive L-3002 (USA) was

used as a surfactant, and cyclopentane (95%, Mw: 70.13 g/mol, SAMCHUN, Korea) was used as a physical co-blowing agent. Melamine particles (M2659, 430±15 μm, Sigma-Aldrich, USA) were used as a filler in the PU composite foam. Evonik PE-40 (Germany) was used as a dispersant to achieve a uniform distribution of melamine particles in the polyol mixture during the premixing step.

Synthesis. Flexible PU foams were fabricated via a one-shot polymerization by mixing a polyol system with isocyanate. First, the polyol system (polyol, gelling catalyst, blowing catalyst, cross-linker, blowing agent, surfactant, co-blowing agent, melamine particles, and dispersant) was weighed in a 1 L paper cup and stirred at 1700 rpm for 10 min. The detailed formulations of the PU composite foams are presented in Table 1. Then, pre-weighed isocyanate was added to the stirred polyol system and stirred at 6000 rpm for 10 s, and the PU mixture was put into an aluminum mold (200×200×50 mm3) for curing at 60 ℃ for 20 min. Finally, the PU foam was removed from the aluminum mold, crushed three times on the front and back of the foam, and stored

at room temperature for three days. All the foam samples were prepared without the skin layer (10 mm outer surface).

Sample Characterization. FTIR Spectroscopy: FTIR spectroscopy (Frontier, PerkinElmer Inc., USA) equipped with an attenuated total-reflectance (ATR)

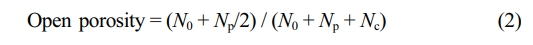

accessory was used to analyze the reaction rates of PU composite foams including cyclopentane and dispersants by comparing the NCO conversion rates. FTIR data were collected in four scans at a resolution of 4 cm-1 and functional group changes were tracked using time-based software. A sample of the reaction mixture was placed on a diamond crystal and scanned at 8-second intervals for 60 min using an ATR accessory. After baseline correction, the NCO conversion was calculated using Eq. (1).

The normalized peak heights of the free NCO stretching band at the start of the reaction and at time t are denoted as I0 and It, respectively. The heights of the free NCO stretching band between 2270 and 2250 cm-1 were normalized using the internal standard peak at 2970 cm-1 (C-H stretching band) during polymerization20,21

Morphology: A scanning electron microscope (SEM, SNE-3000 M, SEC Co. Ltd., at 15 kV, Korea) was used to investigate the microstructure of the foams. A sputter (MCM100, SEC Co. Ltd., Korea) was used to coat a gold film on the sample, and 15 images per sample were obtained and analyzed. The obtained images were analyzed using the Image-Pro Plus software. In each image, we analyzed the number of cavities, open pores, partially open pores, and closed pores and analyzed their average diameters and standard deviations.

Sound Absorption Property: We used two impedance tubes (BSWA SW 470 for the high-frequency, BSWA SW420 for the mid- and low-frequency) installed with two 1/4-inch microphones (MPA416, BSWA) to measure the sound absorption coefficient of the PU composite foams. All samples were cut to 20 mm thickness and diameters of 30 mm and 100 mm for high-frequency (1000-6300 Hz) and mid- and low-frequency (63-1600 Hz) measurements, respectively. To analyze the results from low frequency to high frequency, the VA-Lab software (BSWA) was utilized to combine them and generate a single sound absorption coefficient plot. Also, we analyzed the acoustic activity (AA) and the noise reduction coefficients (NRC). AA was calculated as the average of the absorption coefficients across the entire frequency range, and NRC was obtained by averaging the absorption coefficients at 250, 500, 1000, and 2000 Hz.

Dynamic Mechanical Analysis: The storage modulus (E') and loss modulus (E'') were measured using DMA (Q800, TA Instruments, USA), and the tan d was calculated as E''/E'. Cylindrical samples with a diameter of 40 mm and a thickness of 8 mm were prepared for the measurements, and the measurements were conducted at a heating rate of 5 ℃/min, from -80 ℃ to + 20 ℃, and a frequency of 1 Hz with an amplitude of 40 mm.

|

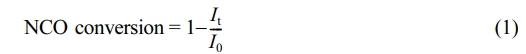

Table 1 Formulation Details for Fabrications of Polyurethane Foams |

*NCO Index: 1.0 |

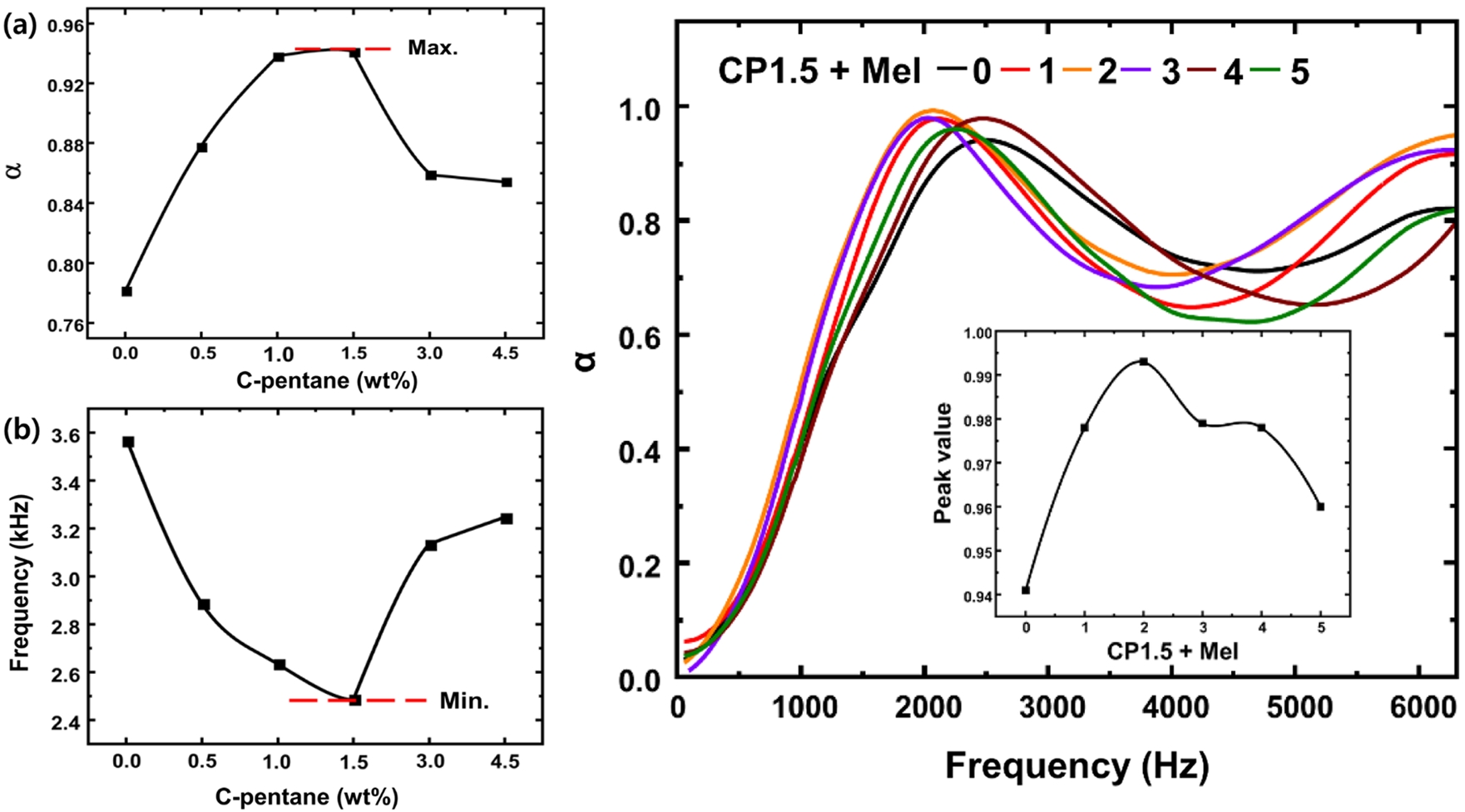

Optimization of the Cyclopentane Content in PU Composite Foams. In the application of cyclopentane as a co-blowing agent, determining the optimal cyclopentane content is important for achieving synergistic performance with a chemical blowing agent (water). Applying cyclopentane and melamine particles in manufacturing the PU composite foams is sequentially investigated for improving the sound absorption coefficient, and firstly the optimal amount of cyclopentane was examined by accessing the sound absorption coefficient.

Morphology: The porous morphology is closely related to the sound absorption characteristics of PU foams. This is because sound waves are significantly affected by the friction between air molecules and cell walls in the foam. The gas from the physical blowing agent

and the CO2 produced by the chemical blowing agent began forming after the polyol system was mixed with the isocyanate. The generated gases gradually increased in amount, and through the process of merging, the bubbles grew, providing nucleation sites. The internal shape of the foam varies depending on the properties of the material used to fabricate polyurethane foam. The formation of fine-sized cavities and pores is effective in improving the sound absorption coefficient and sound wave dispersion. Therefore, it is important to include gas molecules in forming cavities for an appropriate size.

To analyze the morphology of the PU foams according to the cyclopentane content, 15 images per sample were analyzed using Image Pro Plus software to determine the pore size, cavity size, and open porosity. Open porosity was calculated using the following equation:

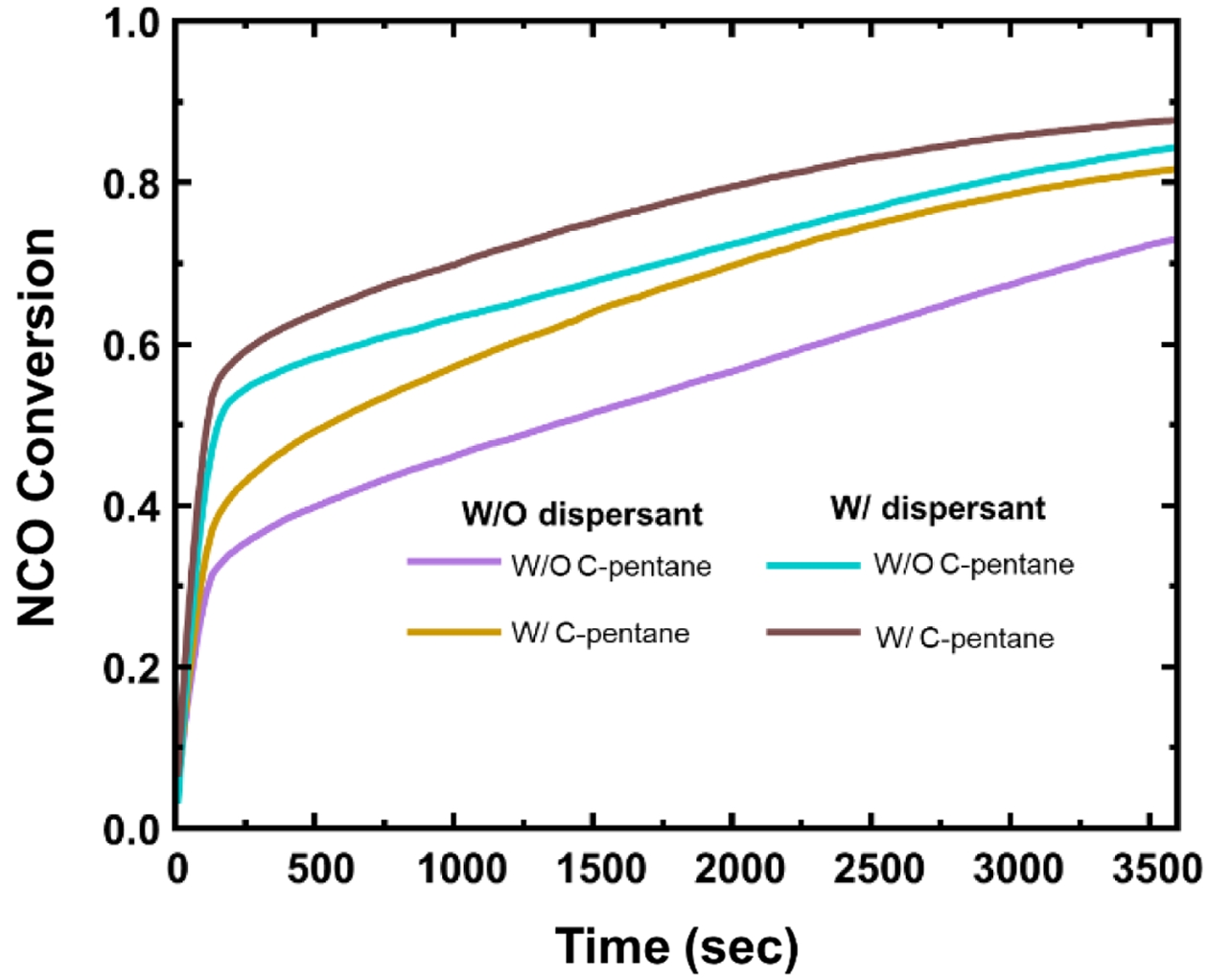

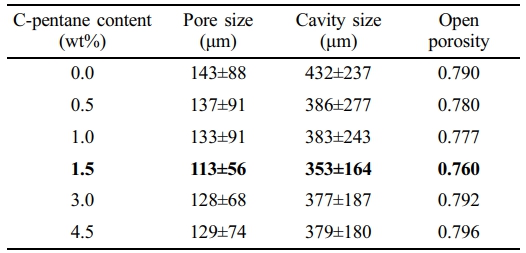

N0, Np, and Nc represent the numbers of open, partially open, and closed pores, respectively.22 Table2 summarizes the cavity and pore sizes and open porosity by varying the cyclopentane contents. As the amount of cyclopentane increased, the cavity and pore sizes gradually decreased. The polymerization and crosslinking reactions of the PU foams generate a significant amount of heat, and the generated heat quickly makes the cyclopentane vaporize, leading to small cavities and pores created.13 However, chemical blowing alone creates CO2 gas molecules gradually, and the formed bubbles have time to merge with other bubbles; thus, the cavity and pore sizes become larger than those from the cyclopentane case. In addition, the use of cyclopentane also reduces viscosity in the polyol system. For example, cyclopentane does not chemically interact with the chains, however when well dispersed in the matrix through high-speed stirring, it spatially inserts itself between the chains, reducing their proximity. This weakens intermolecular interactions, increases chain mobility, lowers viscosity, and ultimately enhances the drainage flow rate. Whether cyclopentane reduces the viscosity of the polyol system can be implied through an NCO conversion rate analysis. Figure 1 shows initial NCO conversion of PU composite foams containing 2 wt% melamine filler, with and without the dispersant and cyclopentane. It demonstrated the highest NCO conversion when both cyclopentane and dispersant were applied in fabrications of the foams. It is possibly because the use of cyclopentane reduces the viscosity of the polyol system, which improves the dispersions of reactive functional groups for increasing the possibility of -OH and -NCO interactions. These phenomena further led to an increase in drainage flow and high NCO conversion.18 On the contrary, the cavity and pore sizes begins to increase after 1.5 wt%, and it is because the viscosity of the polyol system decreased significantly when an excessive amount of cyclopentane was added. Significant viscosity reduction leads to excessive drainage flow, which weakens the cavity walls in the PU foams. This leads to decrease in cavity wall strength, causing the walls to break down during the foaming process. This causes bubble coalescence, leading to an increase cavity and pore sizes.

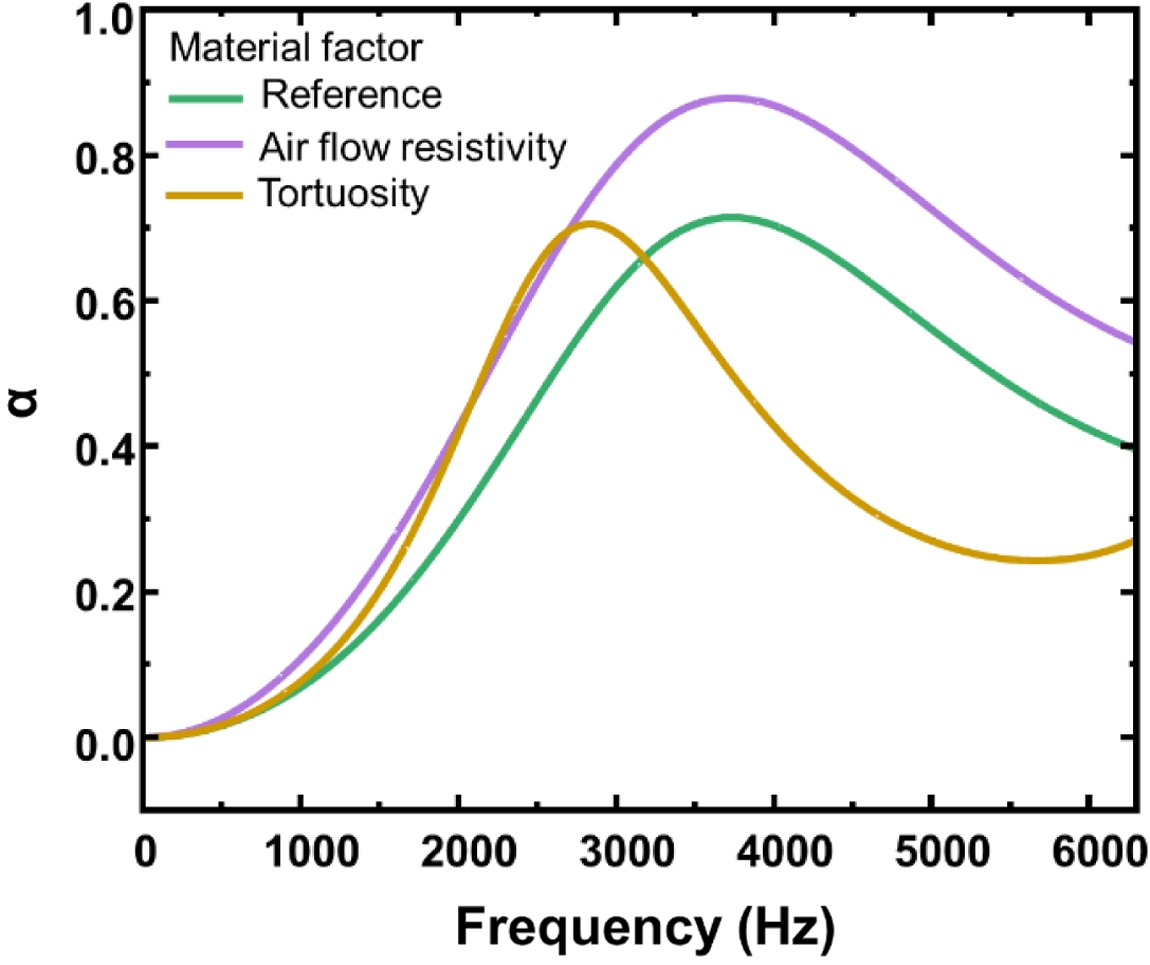

Sound Absorption Coefficient (a): The sound absorption coefficient (a) is expressed as the ratio of the sound waves absorbed to the incident on the PU foams. In general, PU foams absorb sound waves by converting them into heat, which reduces the sound intensity. This property can be interpreted as a major factor in improving the airflow resistance of PU foams, including airflow resistivity and tortuosity. To understand the effect of each parameter on the sound absorption coefficient, model calculations were performed based on previous studies.3,23 Figure 2 shows the sound absorption coefficient (a) according to the effect of air flow resistivity and tortuosity. When the airflow resistivity increased by 60%, the peak value of the sound absorption coefficient increased by approximately 23%. This indicates that the increased airflow resistance led to a decrease in sound energy, and it was found that a decrease in sound energy occurred in the direction where the maximum peak value of the graph shape increased. When the tortuosity increased by 60%, the graph shape shifted

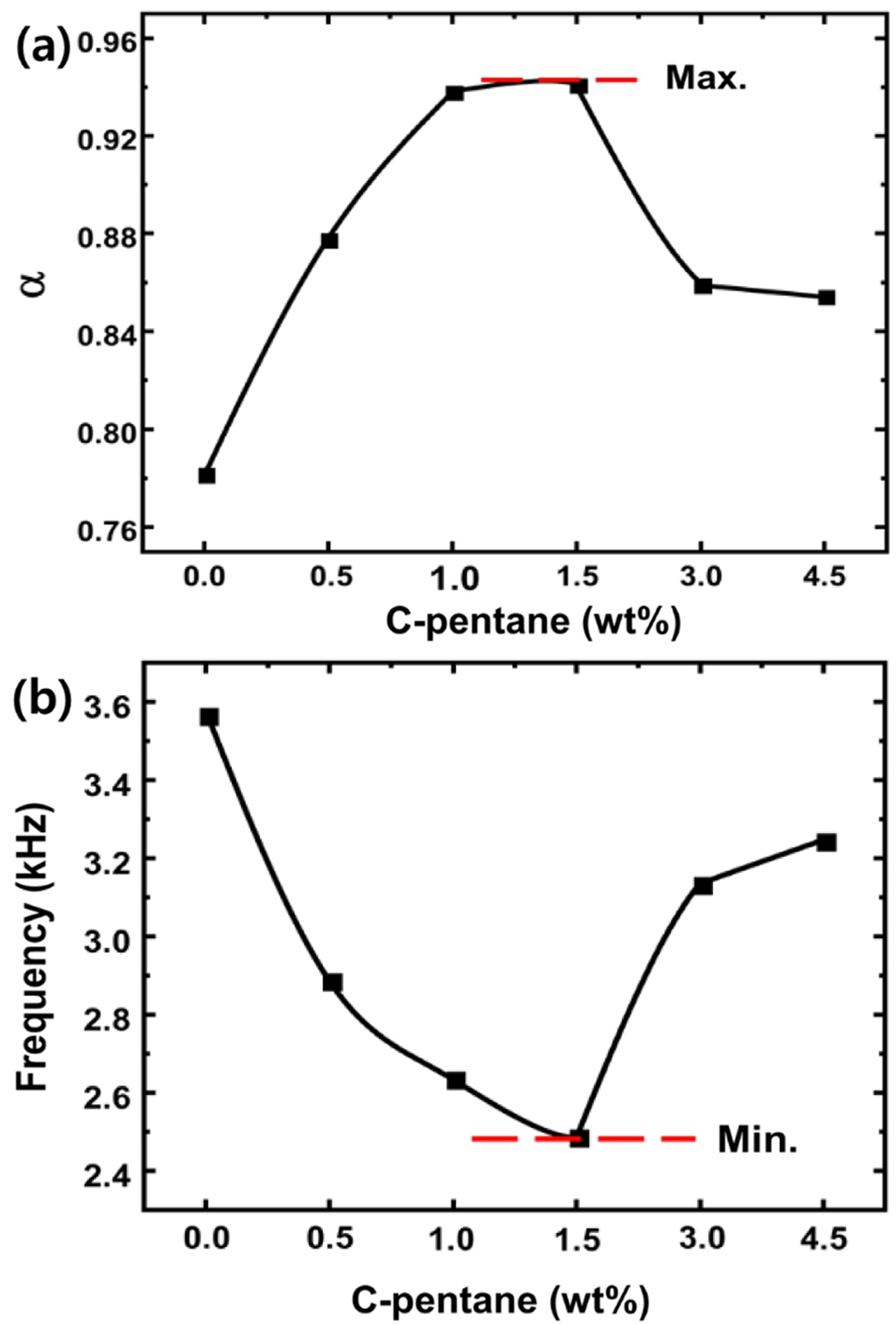

to the low-frequency range. Tortuosity is the actual path lengths (of air molecules through the foam) divided by the material thickness, and so it had the greatest effect at the 1/4 wavelength point. This is the point at which the sound path length through the tortuosity of the PU foam is one-fourth of the wavelength, where the incident and reflected waves meet in opposite phases and cause destructive interference, thereby maximizing the sound absorption performance.24,25 Therefore, the path of the reflected sound increases by half a wavelength due to tortuosity, leading to maximum energy dissipation. Consequently, the increased quarter-wavelength point causes the sound absorption peak to shift toward the low-frequency range. Figure 3 shows the sound absorption coefficients according to cyclopentane contents. As shown in Figure 3(a), the sound absorption coefficient (apeak value) increases up to 1.5 wt% and then decreases. This can be attributed to open porosity (Table 2) and airflow resistivity.16 It promotes reflections and scattering of sound waves in the foams, thereby enhancing sound energy dissipation. Therefore, when the cyclopentane content was 1.5 wt%, it was confirmed that the sample exhibited the smallest open porosity and the largest airflow resistivity. In addition, Figure 3(b) shows the lowest frequency of the maximum peak at 1.5 wt% of cyclopentane. This confirms that the highest tortuosity was achieved when 1.5 wt% of cyclopentane was added. Based on these observations, it can be understood that the best sound absorption characteristics are obtained when 1.5 wt% of the cyclopentane are used. Therefore, in the subsequent experiments for optimizing the contents of additional melamine particles, the cyclopentane was fixed at 1.5 wt%.

Optimization of the Melamine Content in PU Composite Foams. The optimized 1.5 wt% cyclopentane resulted in the best sound absorption properties. In this step, we added melamine particles to PU foams including 1.5 wt% cyclopentane and investigated their effects on the PU foam. Melamine’s -NH2 groups can form hydrogen-bond networks with urethane (-NH-COO-)

groups, potentially enhancing interfacial compatibility with the PU matrix. Therefore, melamine was selected as a filler. In addition, in previous investigations, the use of dispersants played a role in reducing the aggregation phenomenon between fillers, so dispersants were used together with melamine fillers.18

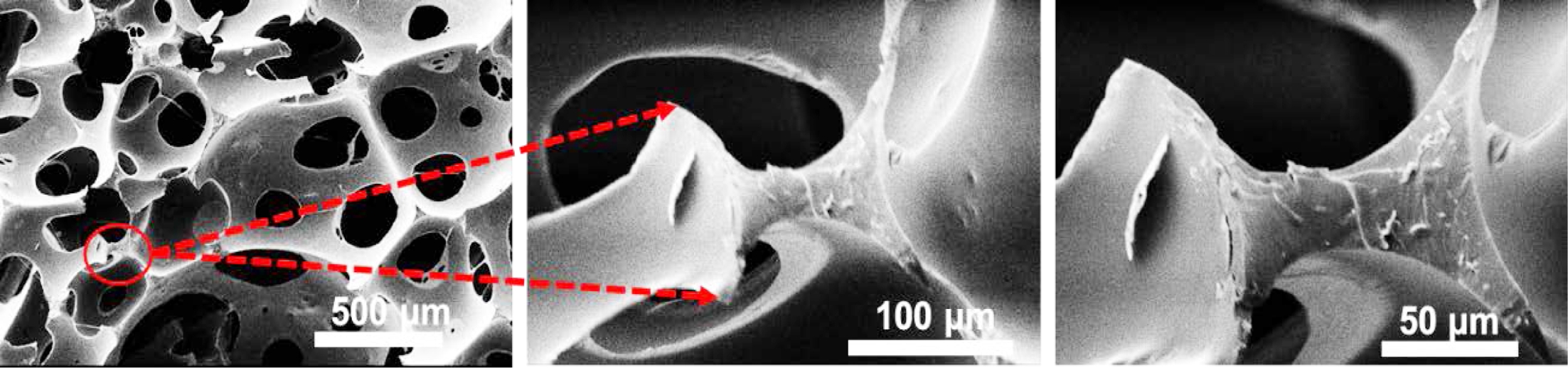

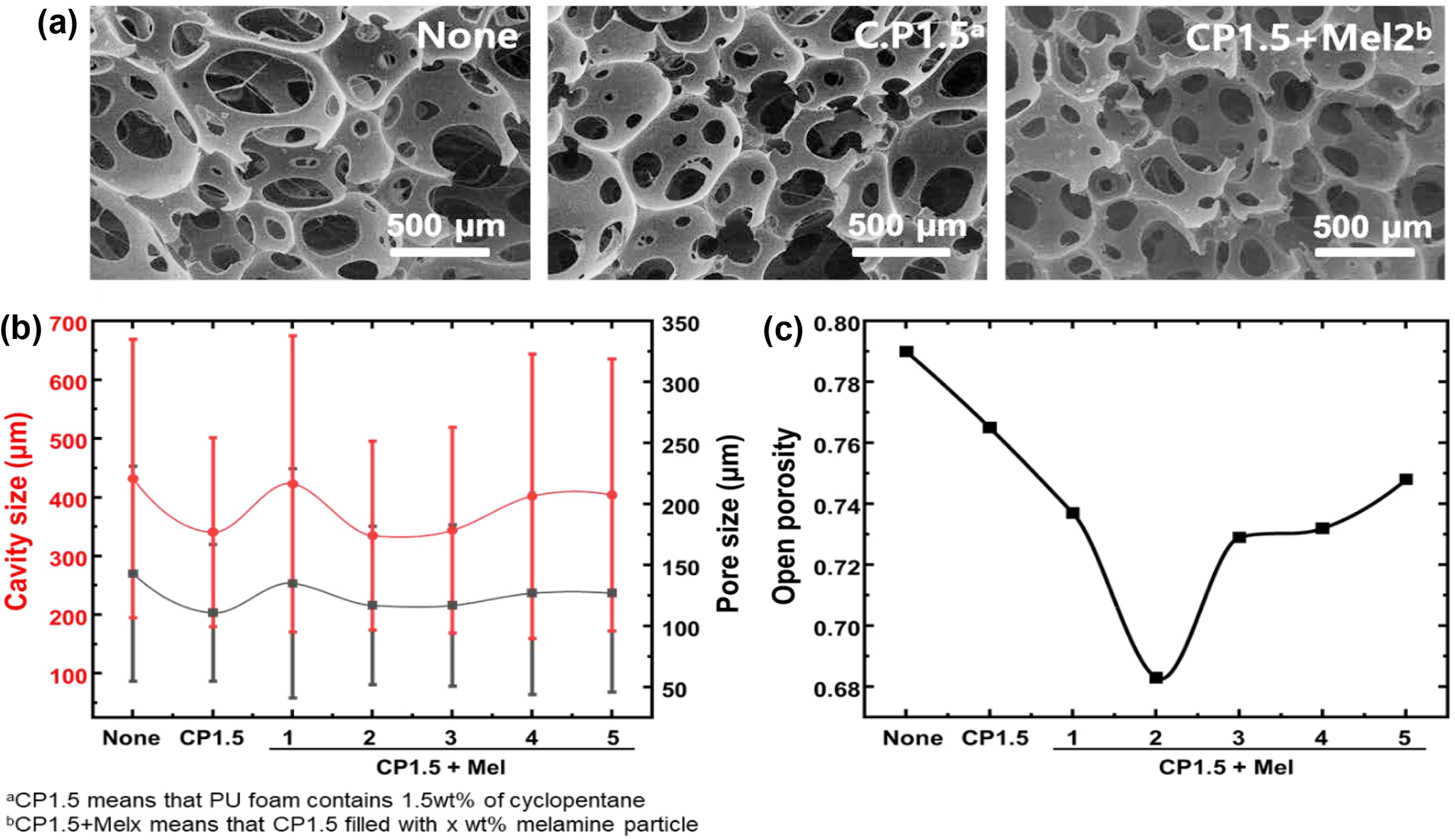

Morphology: The experiment was conducted by adding melamine particles with dispersant. The dispersant interacts with the melamine particles in various ways. It attaches to the surface of the melamine particles and increases the wetting and compatibility with the polyol system. Figure 4 shows that melamine particles with dispersant interact well with PU matrix. In addition, it helps to disperse particles by causing friction on their surface. It also reduces agglomeration by causing static electricity or steric hindrance on the particle surface. The dispersant physically bonds to the melamine surface, causing the nonreactive amine to attach on the surface and generate surface charge that induce electrostatic repulsion between particles. These reduce agglomeration of the melamine particles and viscosity.26,27 Therefore, the increased dispersion stability and decreased viscosity increase the drainage flow, which leads to an increase in the NCO conversion rate. As shown in Figure 1, by comparing the cases with and without cyclopentane, it can be confirmed that the case with the dispersant had a higher NCO conversion rate. Figure 5(a) shows the SEM images after the addition of cyclopentane and melamine particles. This confirmed that the cavity and pore sizes tended to decrease. To analyze the morphology of the melamine particles, 15 images per sample were analyzed to determine the pore size, cavity size, and open porosity. Figure 5(b) shows the cavity size and pore size when melamine particles were added. When 1 wt% melamine particles were added, the pore and cavity sizes increased comparing to the sample with only cyclopentane added. As melamine particles were added, the dispersed particles supported the cavity structure, which was about to shrink, and mechanically reduced the shrink of the foam structure. Thus, the cavity and pore sizes increase temporarily. Also, melamine particles act as nucleation agents that initiate cavity formation.28 This increases the number of nucleation sites, which in turn leads to small cavity and pore sizes. Subsequently, when 2 wt% melamine particles were added, the cavity and pore sizes showed the smallest size. However, it was confirmed that they showed an increasing trend as more particles were added. Excessive amounts of melamine particles can negatively affect the PU foam. This is because the agglomeration of particles can form a larger cavity.29 The agglomeration of the particles can reduce the cavity formation area, which can ultimately increase the cavity size. Therefore, when adding a filler to PU foam, preventing particle agglomeration is the most important factor. In addition to using a dispersant to reduce particle agglomeration, various methods such as surface modification can be used to minimize particle agglomeration.30 Figure 5(c) shows that increasing the amount of melamine particles leads to a decrease in open porosity. This is because the number of open pores is relatively reduced, while the number of partially open pores increases with the addition of melamine particles. Also, the addition of melamine particles increases the viscosity of the polyol system, which in turn reduces the drainage flow rate.18 Thus, the melamine particles support and strengthen the internal cavity structure, resulting in the number of decreasing open pores and increasing partially open pores. This structural change contributes to the scattering and reflection of sound waves in PU foams, thereby affecting its sound absorption performance.

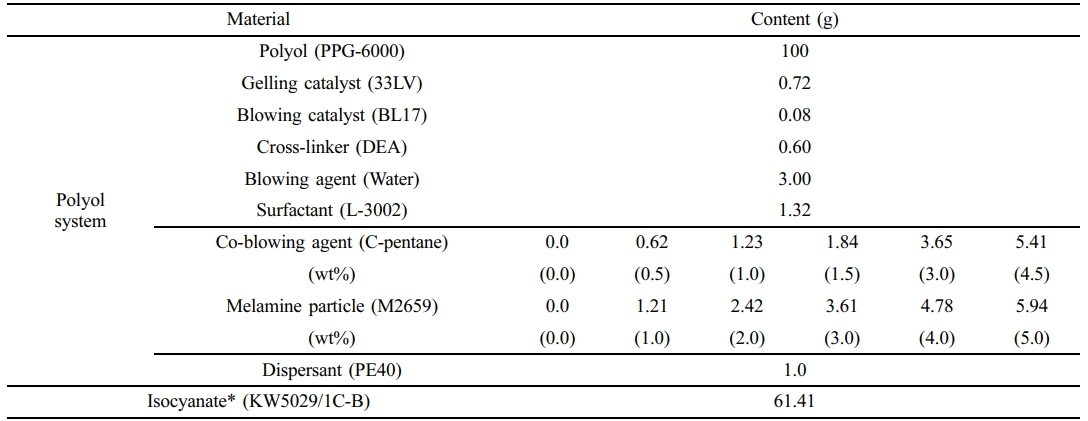

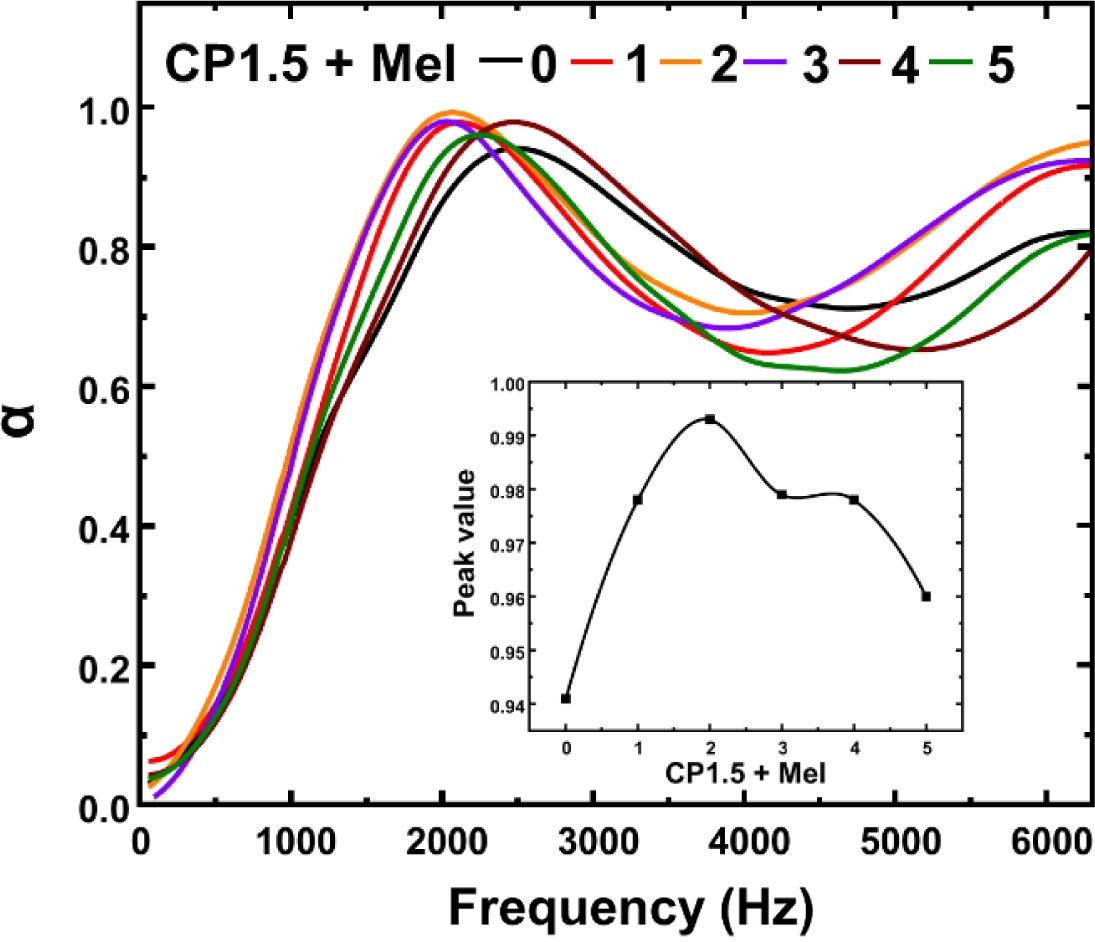

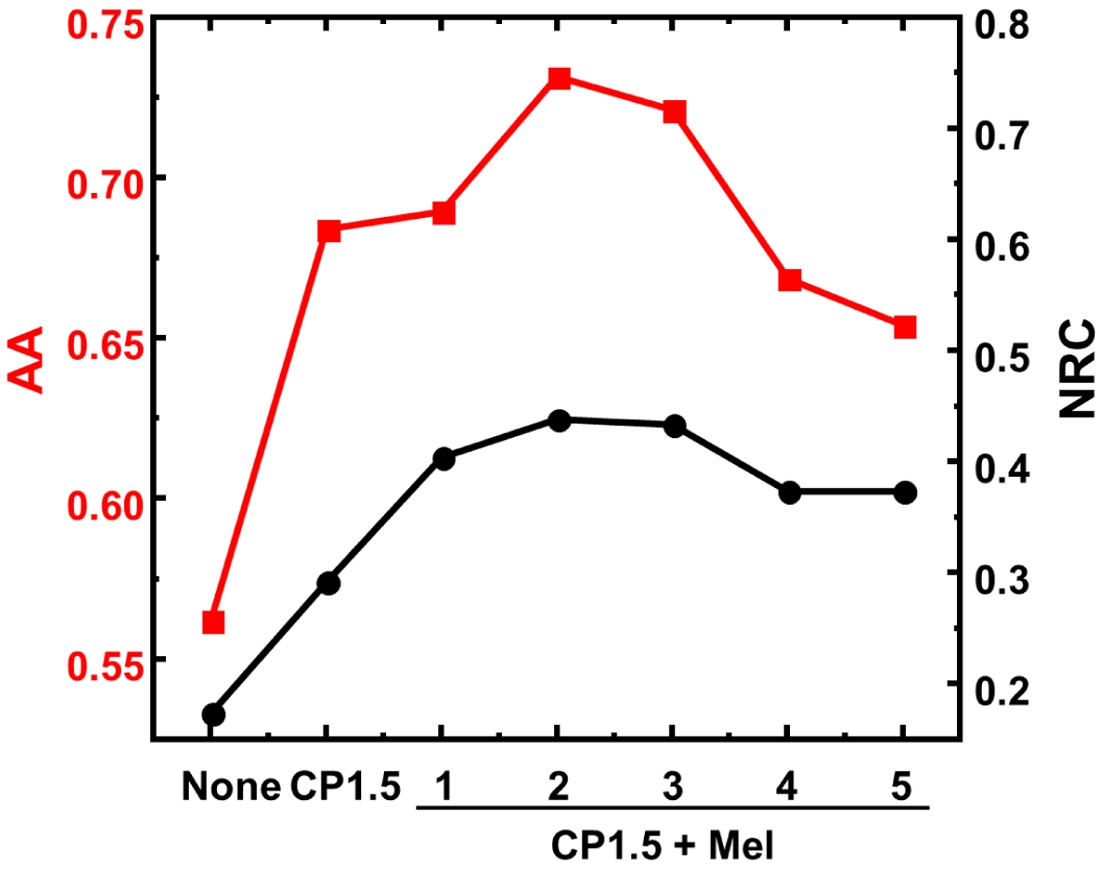

Sound Absorption Coefficient (a): To investigate the effect of melamine particles on the sound absorption coefficient, the sound absorption coefficient according to melamine particle contents was analyzed, as shown in Figure 6. It was confirmed that the sound absorption characteristics improved as the melamine particles increased. This trend showed the best sound absorption characteristics at 2 wt% and then gradually decreased. A similar trend can be observed in the change in open porosity shown in Figure 5(c). This is because the sound absorption characteristics of PU foams are considerably affected by the internal morphology.16 As the open porosity decreases, the possibility of sound waves hitting the cell walls increases, which can induce sound scattering or reflection. When 2 wt% melamine particles were added, it was confirmed that the maximum sound absorption coefficient was 0.993 due to the effects of air flow resistivity and open porosity. For further analysis, various indicators can be used to evaluate the acoustic characteristics. The samples were additionally analyzed by using acoustic activity (AA) and noise reduction coefficient (NRC). The AA was calculated as the average of the sound absorption coefficients in all frequency ranges, and the NRC was calculated as the average of the sound absorption coefficients at 250, 500, 1000, and 2000 Hz.31,32 As shown in Figure 7, it was found that the highest AA and NRC values were shown when 1.5 wt% of cyclopentane and 2 wt% of melamine particles were added together.

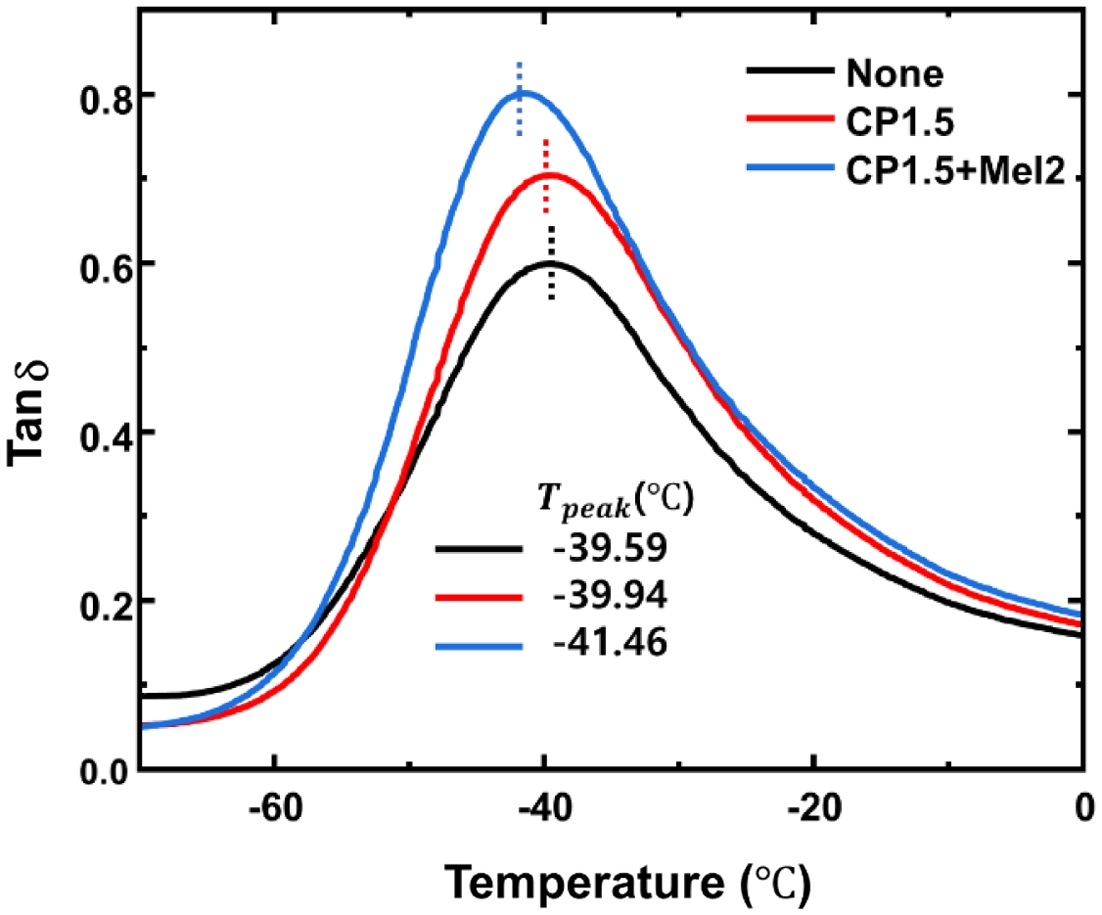

Thermomechanical Properties: Sound waves moving through a porous medium collide with air molecules and cell walls, resulting in sound wave scattering or reflection and causing dissipation of sound energy as heat energy through the vibration-damping motion of the cell walls. This means that the incident sound waves can be converted into heat energy through the vibration-damping of the material itself, ultimately reducing the intensity of the sound waves and enhancing sound absorption. Tan δ is defined as the ratio of the loss modulus to the storage modulus, which is an indicator of how much of the external energy is lost as heat energy in the material. A higher tan δ value means better damping properties.33 In terms of acoustic performance, PU foam is advantageous incident sound waves are dissipated as heat. Figure 8shows the analysis of the thermomechanical properties using representative samples at each step. The highest tan δ peak value was observed in CP1.5+Mel2 sample and the lowest tan δ peak value was observed in the reference sample with no additives. This indicates that the CP1.5+Mel2 sample exhibited the greatest internal heat energy dissipation, resulting in significant damping. Due to the high ability to dissipate energy as heat, excellent sound absorption performance was confirmed in Figure 6 and Figure 7. The glass transition temperature is also expressed as the temperature at the peak value of tan δ (Tpeak). It was confirmed that the lowest Tpeak value was observed in CP1.5+Mel2. This result proves that the CP1.5 + Mel2 sample has good chain mobility in a wide temperature range. These results confirm that superior damping property leads to improved sound absorption performance.

|

Figure 1 Initial NCO conversion of PU composite foams containing 2 wt% melamine filler, with and without the addition of dispersant and cyclopentane. |

|

Figure 2 Model calculation for sound absorption coefficient considering air flow resistivity and tortuosity. It shows the changing graph shape when the airflow resistivity and tortuosity are increased by 60 %. For reference, r = 1.2×104 , s = 1.6, ø = 0.8; 60% increment of airflow resistivity, r = 1.92×104 ; 60% increment of tortuosity, s = 2.56.23 |

|

Figure 3 Sound absorption coefficient according to cyclopentane content in the PU composite foams for (a) the peak values; (b) the peak frequencies. |

|

Figure 4 Typical SEM images of the PU composite foams including 2 wt% melamine particles and cyclopentane 1.5 wt% |

|

Figure 5 (a) Typical SEM images of the PU composite foams including melamine particles and cyclopentane with dispersant; (b) their pore size, cavity size; (c) open porosity. |

|

Figure 6 Sound absorption coefficient according to melamine particle contents with dispersant. |

|

Figure 7 Acoustic activity and noise reduction coefficient according to melamine particle contents with dispersant. |

|

Figure 8 Thermomechanical analysis of tan δ with cyclopentane and melamine particles. |

|

Table 2 Pore Size, Cavity Size, and Open Porosity According to Cyclopentane Content |

In this study, we investigated the effects of cyclopentane and melamine particles on sound-absorbing characteristics. Through morphological analysis, we confirmed the influence of each material and enabled us to determine the optimal content. FTIR analysis confirmed that cyclopentane and dispersant caused a decrease in viscosity within the polyol. Based on model calculations, we identified the shape of the sound absorption coefficient curve that shows superior acoustic performance. The analysis of the sound absorption coefficient identified the sample with optimal acoustic characteristics and determined that the CP1.5+Mel2 sample exhibited the best performance. Thermomechanical analysis revealed that the CP1.5+Mel2 sample showed high tan δ and low Tpeak, which indicates excellent damping performance.

- 1. Oborne, D. J. The Ergonomics of Passenger Comfort Passenger Comfort. Appl. Ergonomics. 1978, 9, 131-136.

-

- 2. Park, N.; Kim, Y.; Park, C. The Effect of Additives on Sound Absorption Coefficient of Polyurethane Foam. J. Kor. Ind. Eng. Chem. 1997, 8, 197-203.

- 3. Fahy, F.; Thompson, D. Fundamentals of Sound and Vibration, 2nd ed.; CRC Press: Boca Raton, 2016; pp 269-278.

- 4. Arjunan, A.; Baroutaji, A.; Robinson, J.; Vance, A.; Arafat, A. Acoustic Metamaterials for Sound Absorption and Insulation in Buildings. Bulid. Environ. 2024, 251, 111250.

-

- 5. Sung, G.; Kim, J. S.; Kim, J. H. Sound Absorption Behavior of Flexible Polyurethane Foams Including High Molecular-weight Copolymer Polyol. Polym. Adv. Technol. 2018, 29, 852-859.

-

- 6. Lee, J.; Kim, J. H. Performance Evaluations of Flexible Polyurethane Foams Manufactured with Castor Oil-based Bio-polyol. Polym. Test. 2023, 124, 108069l.

-

- 7. Gwon, J. G.; Sung, G.; Kim, J. H. Modulation of Cavities and Interconnecting Pores in Manufacturing Water Blown Flexible Poly (urethane urea) Foams. Int. J. Precis. Eng. Manuf. 2015, 16, 2299-2307.

-

- 8. Gwon, J. G.; Kim, S. K.; Kim, J. H. Sound Absorption Behavior of Flexible Polyurethane Foams with Distinct Cellular Structures. Mater. Des. 2016, 89, 448-454.

-

- 9. Choe, H.; Kim, J. H. Reactivity of Isophorone Diisocyanate in Fabrications of Polyurethane Foams for Improved Acoustic and Mechanical Properties. J. Ind. Eng. Chem. 2019, 69, 153-160.

-

- 10. Sung, G.; Kim, S. K.; Kim, J. W.; Kim, J. H. Effect of Isocyanate Molecular Structures in Fabricating Flexible Polyurethane Foams on Sound Absorption Behavior. Polym. Test. 2016, 53, 156-164.

-

- 11. Kim, S. K.; Sung, G.; Gwon, J. G.; Kim, J. H. Controlled Phase Separation in Flexible Polyurethane Foams with Diethanolamine Cross-linker for Improved Sound Absorption Efficiency. Int. J. Precis. Eng. Man-GT. 2016,3, 367-373.

-

- 12. Brondi, C.; Maio, E. D.; Bertucelli, L.; Parenti, V.; Mosciatti, T. Competing Bubble Formation Mechanisms in Rigid Polyurethane Foaming. Polymer. 2021, 228, 123877.

-

- 13. Choe, K. H.; Soo, D. L.; Seo, W. J.; Kim, W. N. Properties of Rigid Polyurethane Foams with Blowing Agents and Catalysts. Polym. J. 2004,36, 368-373.

-

- 14. Sung, G.; Kim, J. H. Influence of Filler Surface Characteristics on Morphological, Physical, Acoustic Properties of Polyurethane Composite Foams Filled with Inorganic Fillers. Compos. Sci. Technol. 2017, 146, 147-154.

-

- 15. Sung, G.; Kim, J. W.; Kim, J. H. Fabrication of Polyurethane Composite Foams with Magnesium Hydroxide Filler for Improved Sound Absorption. J. Ind. Eng. Chem. 2016, 44, 99-104.

-

- 16. Yun, D.; Kim, J. H. Performance Enhancements of PU Composite Foams Reinforced with Starfish Particles Chemically Treated by Silane Derivatives. Adv. Powder Technol. 2024, 35, 104349.

-

- 17. Choe, H.; Lee, J. H.; Kim, J. H. Polyurethane Composite Foams Including CaCO3 Fillers for Enhanced Sound Absorption and Compression Properties. Compos. Sci. Technol, 2020, 194, 108153.

-

- 18. Yun, D.; Kim, J. H. Acoustic Performance of Flexible Polyurethane Composite Foams Filled with Melamine Particles. Korean J. Chem. Eng. 2023, 40, 3052-3058.

-

- 19. Kim, J. Y.; Kim, J. D.; Kim, J. H.; Kim, S. K.; Lee, J. M. Effects of Ultrasonic Dispersion on Nanoparticle Based Polyurethane Foam Reinforcement. Polym. Test. 2021, 99, 107210.

-

- 20. Kasprzyk, P.; Głowińska, E.; Datta, J. Structure and Properties Comparison of Poly(ether-urethane)s Based on Nonpetrochemical and Petrochemical Polyols Obtained by Solvent Free Two-step Method. Eur. Polym. J. 2021,157, 110673.

-

- 21. Cao, N. J.; Huang, C. F.; Li, Y.; Zhao, L.; Zhang, G. D.; Gao, J. F.; Guan, L. Z.; Jiang, J. X.; Tang, L. C.Silane Grafted Graphene Oxide Papers for Improved Flame Resistance and Fast Fire Alarm Response. Compos. Pt. B: Eng. 2019,168, 413-420.

-

- 22. Zhang, C.; Li, J.; Hu, Z.; Zhu, F.; Huang, Y. Correlation Between the Acoustic and Porous Cell Morphology of Polyurethane Foam: Effect of Interconnected Porosity. Mater. Des. 2012, 41, 319-325.

-

- 23. Choe, H.; Sung, G.; Kim, J. H. Chemical Treatment of Wood Fibers to Enhance the Sound Absorption Coefficient of Flexible Polyurethane Composite Foams. Compos. Sci. Technol. 2018, 156, 19-27.

-

- 24. Arjunan, A. Acoustic Absorption of Passive Destructive Interference Cavities. Mater. Today Commun. 2019, 19, 68-75.

-

- 25. Trinh, V. H.; Langlois, V.; Guilleminot, J.; Perrot, C.; Khidas, Y.; Pitois, O. Tuning Membrane Content of Sound Absorbing Cellular Foams: Fabrication, Experimental Evidence and Multiscale Numerical Simulations. Mater. Des. 2019, 162, 345-361.

-

- 26. Nadiv, R.; Vasilyev, G.; Shtein, M.; Peled, A.; Zussman, E. Regev, O. The Multiple Roles of a Dispersant in Nanocomposite Systems. Compos. Sci. Technol. 2016,133, 192-199.

-

- 27. Das, D.; Das, S. K.; Parhi, P. K.; Dan, A. K.; Mishra, S.; Misra, P. K. Green Strategies in Formulating, Stabilizing and Pipeline Transportation of Coal Water Slurry in the Framework of WATER-ENERGY NEXUS: A State of the Art Review. Sci. Technol. 2021, 4, 100025.

-

- 28. Stanzione, M.; Oliviero, M.; Cocca, M.; Errico, M. E.; Gentile, G.; Avella, M.; Lavorgna, M.; Buonocore, G. G.; Verdolotti, L. Tuning of Polyurethane Foam Mechanical and Thermal Properties Using Ball-milled Cellulose. Carbohydr. Polym. 2020,231, 115772.

-

- 29. El-Metwaly, E. A.; Mohamed, H. E.; El-Basheer, T. M.; Moselhy, M. T. H.; Zulfiqar, S.; Cochran, E. W.; Maamoun, A. A. Eco-conscious Upcycling of Sugarcane Bagasse Into Flexible Polyurethane Foam for Mechanical & Acoustic Relevance. RSC Adv. 2024,14, 23683-23692.

-

- 30. Hwang, U.; Lee, B.; Oh, B.; Shin, H. S.; Lee, S. S.; Kang, S. G.; Kim, D.; Park, J.; Shin, S.; Suhr, J.; Kim, S. H.; do Nam, J. Hydrophobic Lignin/polyurethane Composite Foam: An Eco-friendly and Easily Reusable Oil Sorbent. Eur. Polym. J. 2022,165, 110971.

-

- 31. Tiuc, A. E.; Vermeşan, H.; Gabor, T.; Vasile, O. Improved Sound Absorption Properties of Polyurethane Foam Mixed with Textile Waste. Energy Procedia. 2016, 85, 559-565.

-

- 32. Verdejo, R.; Stämpfli, R.; Alvarez-Lainez, M.; Mourad, S.; Rodriguez-Perez, M. A.; Brühwiler, P. A.; Shaffer, M. Enhanced Acoustic Damping in Flexible Polyurethane Foams Filled with Carbon Nanotubes. Compos Sci. Technol. 2009,69, 1564-1569.

-

- 33. Najib, N. N.; Ariff, Z. M.; Bakar, A. A.; Sipaut, C. S. Correlation Between the Acoustic and Dynamic Mechanical Properties of Natural Rubber Foam: Effect of Foaming Temperature. Mater. Des. 2011, 32, 505-511.

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2024 Impact Factor : 0.6

- Indexed in SCIE

This Article

This Article

-

2026; 50(1): 84-92

Published online Jan 25, 2026

- 10.7317/pk.2026.50.1.84

- Received on Jun 27, 2025

- Revised on Sep 3, 2025

- Accepted on Sep 10, 2025

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

- Conflict of Interest

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jung Hyeun Kim

-

Department of Chemical Engineering & Center for Innovative Chemical Processes (Institute of Engineering), University of Seoul, 163 Seoulsiripdae-ro, Dongdaemun-gu, Seoul 02504, Korea

- E-mail: jhkimad@uos.ac.kr

- ORCID:

0000-0003-4550-5507

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.