- Adsorption Behaviors and Mechanism of Single/Multi-Metals by Ion Exchange Resins

Xinping Qian, Shaohui Lin, Xianshe Feng*, Garry L. Rempel*, Henry Grace*, and Qinmin Pan†

Green Polymer and Catalysis Technology Laboratory, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou 215123, Jiangsu Province, People’s Republic of China

*Department of Chemical Engineering, University of Waterloo, Waterloo, Ontario N2L 3G1, Canada

- 이온 교환 수지에 대한 금속 이온의 흡착 거동 및 메카니즘 연구

Adsorption of Fe(Ш), Co(II),

Cu(II), Zn(II) and K(I) by strong acid resins, Dowex 50WX2 200-400 (H) and

Amberlite IRP-69, was studied to investigate the adsorption behaviors and

mechanism in single-metal and multi-metal systems. The results showed that

99.9% Fe(III) can be removed by Dowex 50WX2 200-400 (H) in 100 min ([Fe(Ш)]

< 40 mg/L, resin amount = 50 mg, pH = 3.0, 60 ºC). Mechanism studies

revealed that Langmuir model and pseudo-second-order kinetic equation

illustrate better fit for the adsorption of Fe(Ш). Furthermore, the

investigations on multi-metal adsorption indicated that resins display a

similar adsorption ratio for the same-valence metal ions (Co(II) = Cu(II) =

Zn(II)), and a more selective adsorption for high-valence metal ions than

low-valence metal ions (Fe(III) > Co(II) > K(I)). The above results can

be used for the treatment of wastewater and the recovery of metals from the

spent catalysts.

The adsorption behaviors and mechanism of metal were

studied in single/multi-metal systems by Dowex 50WX2 200-400 (H) and Amberlite

IRP-69. The results showed that 99.9% Fe(III) can be removed by Dowex 50WX2

200-400 (H) in 100 min ([Fe(III)] < 40 mg/L, resin amount = 50 mg,

pH = 3.0, 60 ¨¬C), and both resins exhibited better selectivity

towards metal ions with high-valence than those with low-valence.

Keywords: adsorption, ion exchange, metal, kinetic, separation

Financial support from the National Natural Science Foundation of China

(No. 21176163; No. 21576174), Suzhou Industrial Park, the Priority Academic

Program Development of Jiangsu Higher Education Institutions and the Program of

Innovative Research Team of Soochow University are gratefully acknowledged.

In recent decades, metals have played an increasingly important role in

chemical production and human life, especially transition metals, which have

been widely used in catalysts,1 electroplating, batteries, etc..

However, the heavy metals2 (Fe, Co, Cu) in industry wastewater are

harmful to ecological environment, and discharging them directly pollutes the

water and soil, further endangers biological life and human health. In

addition, discarding the rare metals and precious metals (Pt, Pd, Rh) in spent

catalysts leads to the waste of resources.3 Therefore, separation

and recovery of transition metals from these wastes is particularly significant

for environmental protection and secondary use concern. At present, various

techniques have been employed to separate metals from solution such as

precipitation, solvent extraction, membrane filtration, and ion exchange.4

In the early research, precipitation was widely applied in separation of metals

from aqueous solution. Meanwhile, it has been found to be in efficient.5

Solvent extraction is another common method used in metals recovery, which can

improve the adsorption selectivity and efficiency. However, the use of organic

solvents has caused secondary pollution to the environment.6

Membrane separation was also discovered as a viable way to separate metals.4

The implementation of this method can reduce the use of organic solvents, but

the filter membrane is easily clogged. With the development of advanced

technology in separation areas, ion exchange was presented with high metal

selectivity and efficiency.7 It is generally employed in water

treatment, metal separation, and catalysis.8,9 These resins used

today are typically made of small beads of highly crosslinked polymers that

contain functional groups which facilitate the ion exchange.10,11

Consequently, metals can be separated from the solution by ion exchange when

their concentration is low. Moreover, ion exchange is environment friendly, and

the resins can be reused for many times after the adsorption-desorption

process.

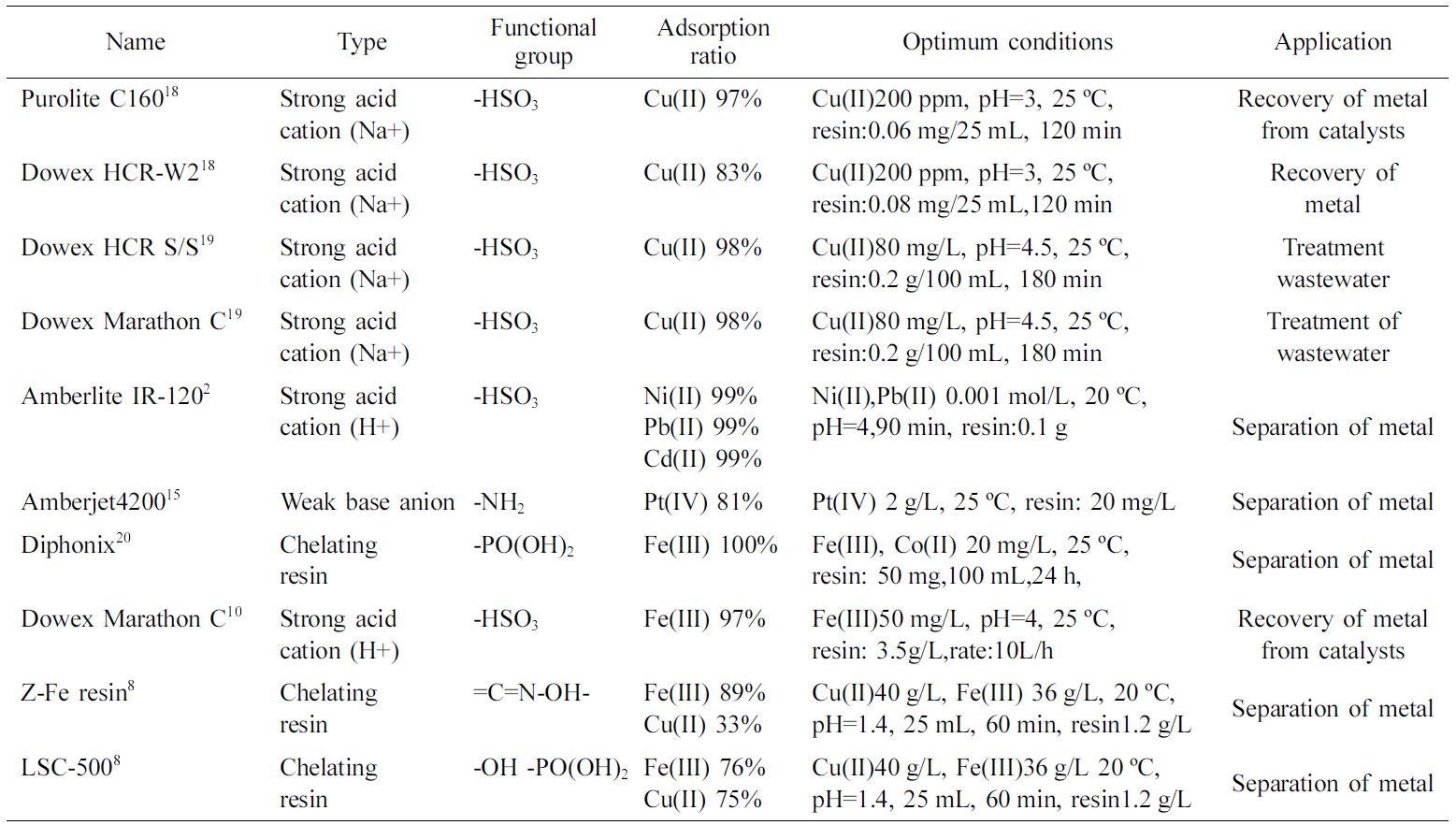

Nowadays, many studies on ion exchanges have been devoted to the

separation of metals. Molybdenum can be separated from chloride leach liquors

in Nguyen’s survey which verified the possibility of Mo separation among Co and

Al with

AG1-x8 resin.12 Aboul-Magd found that Dowex HRWX2-Na exhibits great

adsorption for Fe(III), Cu(II), and Zn(II) in the presence of acid or organic

solute.13 Also, Duclos proposed to recover Pt from fuel cell

catalysts by combining extraction, ion exchange, and precipitation, resulting

in 76% Pt being recovered as solid (NH4)2PtCl6.14

Moreover, Sun published a literature about the recovery of Pt from chloride

leaching solution in which 99.6% Pt was obtained after the elution step.15

In the above work, ion exchange has been shown to be an efficient method for

separating metals, and the choice of resin is especially crucial.

Many factors affect the adsorption capacity of resins, the most

significant is the functional group of which the resin contains.16,17

A variety of resins were examined for the removal of metals from various

solutions. It was reported to have removed Cu(II) from aqueous solution by

using Dowex HCR S/S and Dowex Marathon C, strong acid cation resins with

functional group -SO3H, which resulted in a more than 98% Cu(II)

removal efficiency under optimum conditions.18 The adsorption of

Cu(II), Zn(II), Ni(II), Pb(II), and Cd(II) was surveyed using Amberlite IR-120

synthetic resin, whose functional group is also -SO3H.19

These bivalent metals could be removed completely from aqueous solution but the

marked selectivity of an individual ion by this resin was not shown. Diphonix,

a chelating resin, was used for Fe(Ш) removal from cobalt sulfate solution. Fe(Ш)

was able to be separated efficiently from the Fe(Ш)-Co(II) acid solution when

the acidity was controlled at pH = 1.20 A number of papers reported

metal recovery from solutions by different types of resins. As shown in Table

1.

Pertinent data was obtained from Table 1, and it revealed that strong acid

cation resins with -SO3H group have a superior affinity for metal

cations, which provides a basis for the choice of resins in our research.

Amberlite IR-120 resin also showed similar adsorption capacity with metals of

the same valence but is not studied further. Also, most of the methods

previously mentioned require several adsorption and multiple cycle steps.

Therefore, the easily operable and efficient resins are needed to investigate

the separation of these metals.

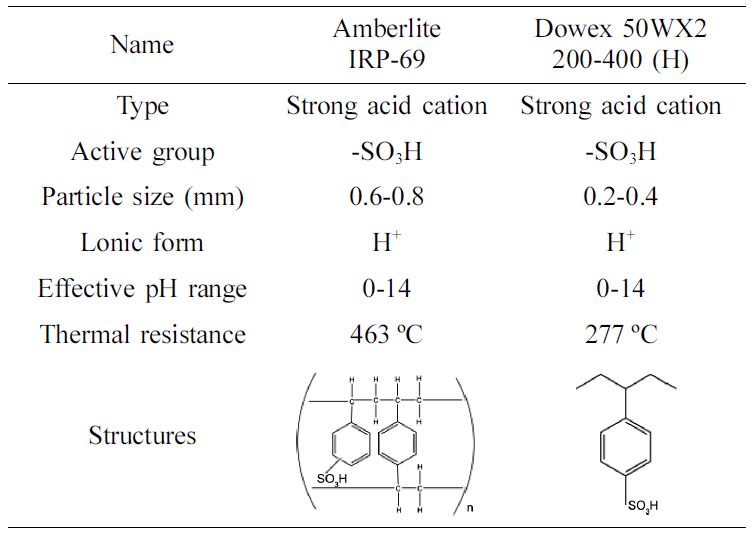

Two strong acid cation resins,

Dowex 50WX2 200-400 (H) and Amberlite IRP-69, were typically chosen as for this

report. These two resins are easily obtained for laboratory and industry use

and are selected because of their low price. This research aims to test an

efficient resin to separate Fe(III) from aqueous solution in sing-metal system

and study the adsorption behaviors and rules of the resins for Co(II), Cu(II)

and Zn(II) ions in multi-metal system. The research investigated the effect of

contact time, pH, temperature, metal concentration, and resin dosage for

effective metal removal, and studied the influencing factors of the selective

adsorption for multiple ions. Furthermore, adsorption isotherm models and

kinetics were investigated.

Materials

and Instruments. All reagents were of analytical grade and all solutions

were prepared in deionized water. The Amberlite IRP-69 and Dowex 50WX2 200-400

(H) resins were purchased from Suzhou Ketong Biological Pharmaceutical

Technology Co. Ltd and Shanghai J&K Chemical Ltd. The properties of

Amberlite IRP-69 and Dowex 50WX2 200-400 (H) are showed in Table 2. Sulfuric

acid and sodium hydroxide were purchased from Chinasun Specialty Products Co.

Other chemicals, Fe2(SO4)3 (M=399.88 g/mol),

CoSO4· 7H2O (M=281.10 g/mol), CuSO4·5H2O

(M=249.69 g/mol), ZnSO4·7H2O (M=287.56 g/mol), and KCl

(M=74.5 g/mol) were purchased from Suzhou Industrial Park Instrument Co.

Ltd.

The pH of the aqueous solution was controlled by sulfuric acid (30 g/L)

and sodium hydroxide (30 g/L) and was tested by pH meter. The metal

concentration was measured by direct coupled plasma atomic emission

spectrometer (ICP-OES, 710-ES, Varian). The resins were dried in a vacuum

drying oven at 30 ℃.

Preparation

of Resins. Firstly, the resins need to be treated before the

adsorption experiments. 2.0 g resin was washed twice with 20 mL sulfuric

acid (30 g/L) to remove the possible metal complex residuals, then washed again

with deionized water to adjust the resins back to be neutral. The resins were

filtered and put in the vacuum drying oven at 30 ℃ until the weight was

constant. The treated resins were then ready for the experiments.

Single-metal

Adsorption. In a single-metal

system, 10 mg/L synthetic solution of Fe(III) was prepared with Fe2(SO4)3.

100 mL above synthetic solution and 20 mg Dowex 50WX2 200-400 (H) or Amberlite

IRP-69 resin were added into a 150 mL conical flask with the magneton. The

mixture was then stirred at 25 ℃ for 100 min in an oil bath (pH = 2). The

20 mL liquid after reaction was taken for concentration test. The resin was

then filtered and dried.21

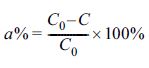

The adsorption ratio a% was calculated by the following equation:

(1)

(1)

where C0 (mg/L) is the initial metal

concentration and C (mg/L) is the final metal concentration after the

reaction.

Multi-metal Adsorption. In multi-metal

systems, The Co(II)- Cu(II)-Zn(II) multi-metal system (2-MMS) was prepared with

CoSO4·7H2O, CuSO4·5H2O, and ZnSO4·7H2O

in aqueous solution. The Fe(III)-Co(II)-Cu(II)-Zn(II) multi-metal system (32-MMS)

was prepared with Fe2(SO4)3, CoSO4·7H2O,

CuSO4·5H2O and ZnSO4·7H2O in

aqueous solution. The Fe(III)-Co(II)-K(I) multi-metal system (321-MMS) was

prepared with Fe2(SO4)3, CoSO4·7H2O

and KCl in aqueous solution. The above adsorption processes in multi-metal

systems proceeded in 100 mL aqueous solution containing metal ions with

Dowex 50WX2 200-400 (H) or Amberlite IRP-69 (contact time = 100 min, pH = 3, T =

25 ℃, ions concentration is 10 mg/L for each metal). The ion

concentrations in the solution were analyzed by ICP-OES, and the adsorption

ratio a% was calculated by eq. (1).

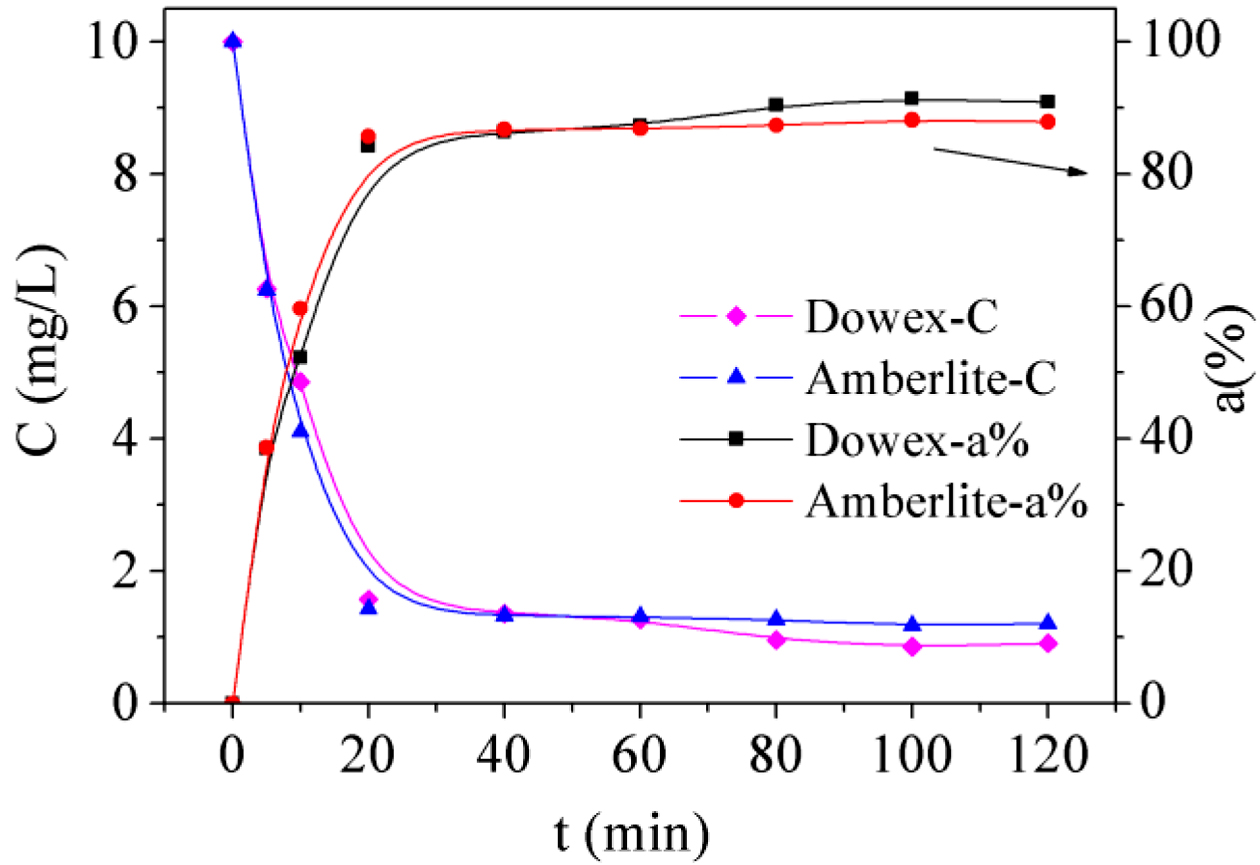

Fe(III) Adsorption in Single-metal System. Effect of Contact Time: The influence of

contact time was investigated regarding the adsorption reaction involving

20 mg Dowex 50WX2 200-400 (H) or Amberlite IRP-69 in 100 mL Fe(III)

solution (10 mg/L). As showed in Figure 1, with the increase of contact time,

the adsorption ratio of Fe(III) increased. The adsorption curve then tends to

level off. This can be described as attainment of adsorption equilibrium. It is

difficult to have more adsorption under these experimental conditions as most

active sites in the resins were already occupied by Fe(III).22 The

adsorption reaction was a fast process of ion exchange, consequently, the

adsorption ratio (a%) was over 80% for Dowex 50WX2 200-400 (H) in the first 20

min, and 91.4% in 100 min at which it achieved an equilibrium state.

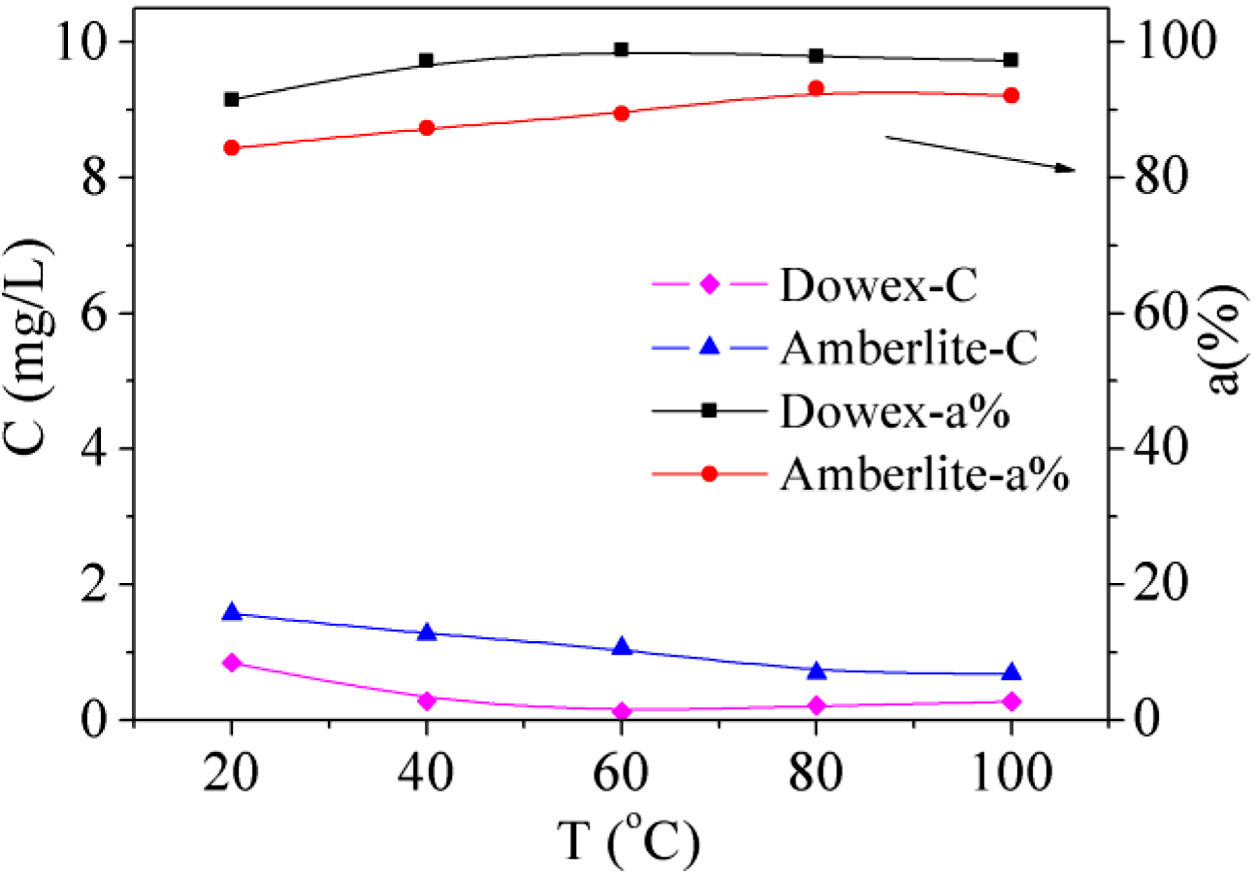

Effect

of Temperature: The effect of temperature on adsorption of Fe(III) by Dowex

50WX2 200-400 (H) and Amberlite IRP-69 was also studied in the experiments. The

temperatures were changed from 20 to 100 ℃ while all other conditions

were invariable. The remnant Fe(III) concentration and adsorption ratio are shown

in Figure 2. When the temperature was under 60 ℃ the adsorption ratio of Dowex

50WX2 200-400 (H) increased, which can be described by the fact that the

adsorption process was more favored than desorption at lower temperature when

the adsorption amount was within the maximum capacity of resin. While the

temperature was above 60 ℃ it decreased slightly because that some Fe(III) was

released from the resin with the increasing temperature. Consequently, the

optimum temperature was found to be 60 ℃ for Dowex 50WX2 200-400 (H) and 80 ℃

for Amberlite IRP-69, and Dowex 50WX2 200-400 (H) shows a better affinity for

Fe(III) with the effect of temperature.

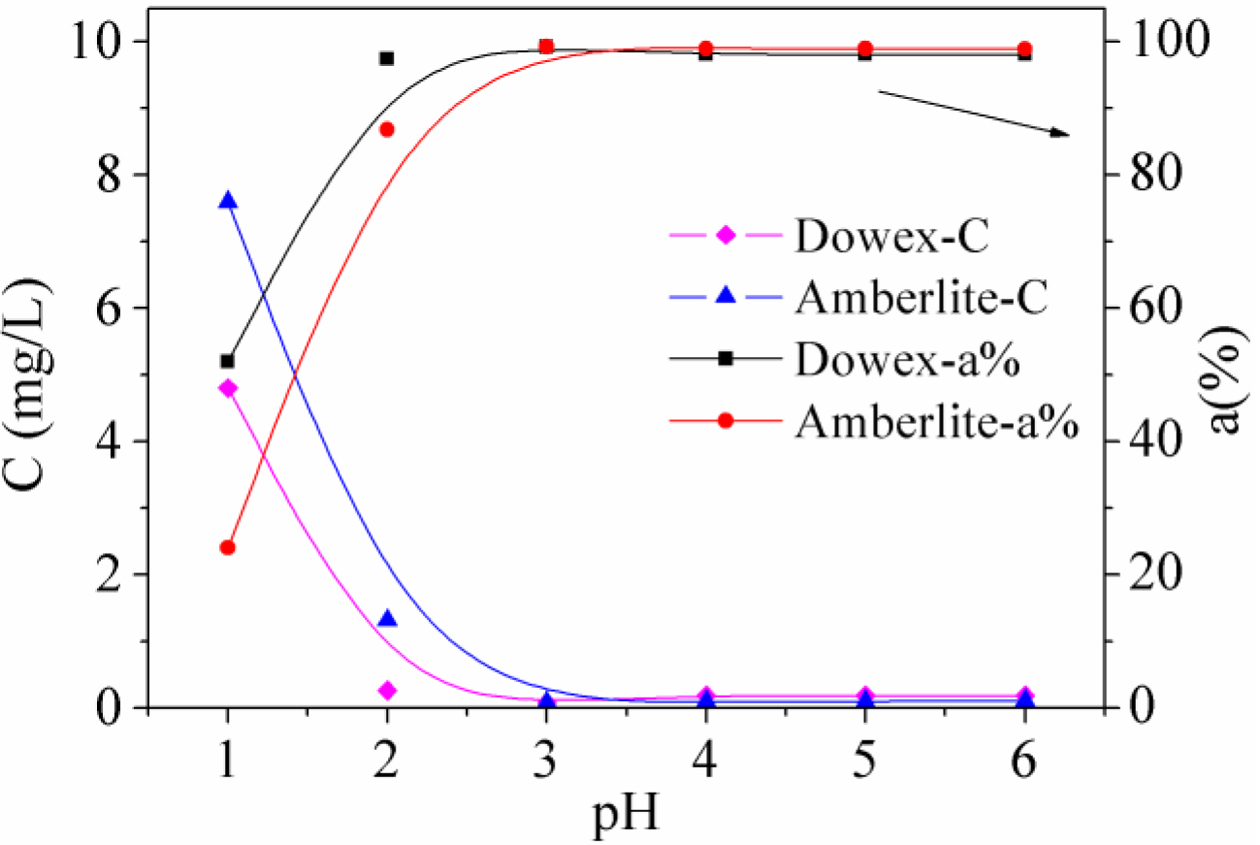

Effect

of pH: A series of experiments were performed using Dowex 50WX2

200-400 (H) and Amberlite IRP-69 to remove Fe(III) under different acidic

conditions. The impact of acidity on the adsorption was examined under the

optimum conditions obtained from the previous experiments. This study varied

the pH values in the range 1 - 6 and the Fe(III) concentration of the solution

were measured by ICP-OES. The results are shown in Figure 3. The investigation

in the effects of pH demonstrated a distinct influence on the adsorption. The

Fe(III) adsorption ratios of two resins were found to be quite low in the very

acidic conditions. Then the ratio increased rapidly until it plateaued with a

maximum recovery of Fe(III) at about 98% with a pH = 3. The resins in solutions

with lower pHs showed poor adsorption capacity because the extremely acidic

conditions inhibit the stripping process of protons from the -SO3H

group, thus reducing the ion exchange efficiency of the resins.

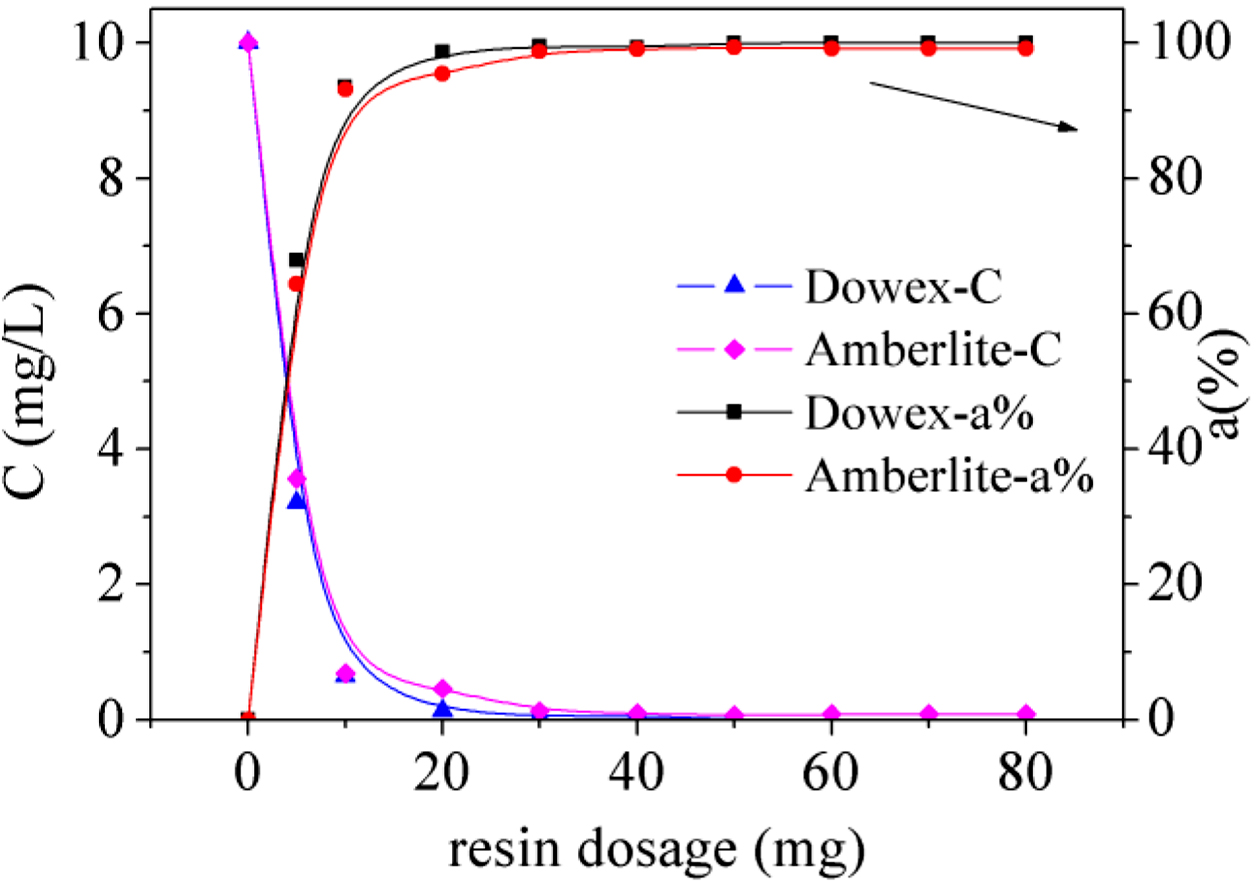

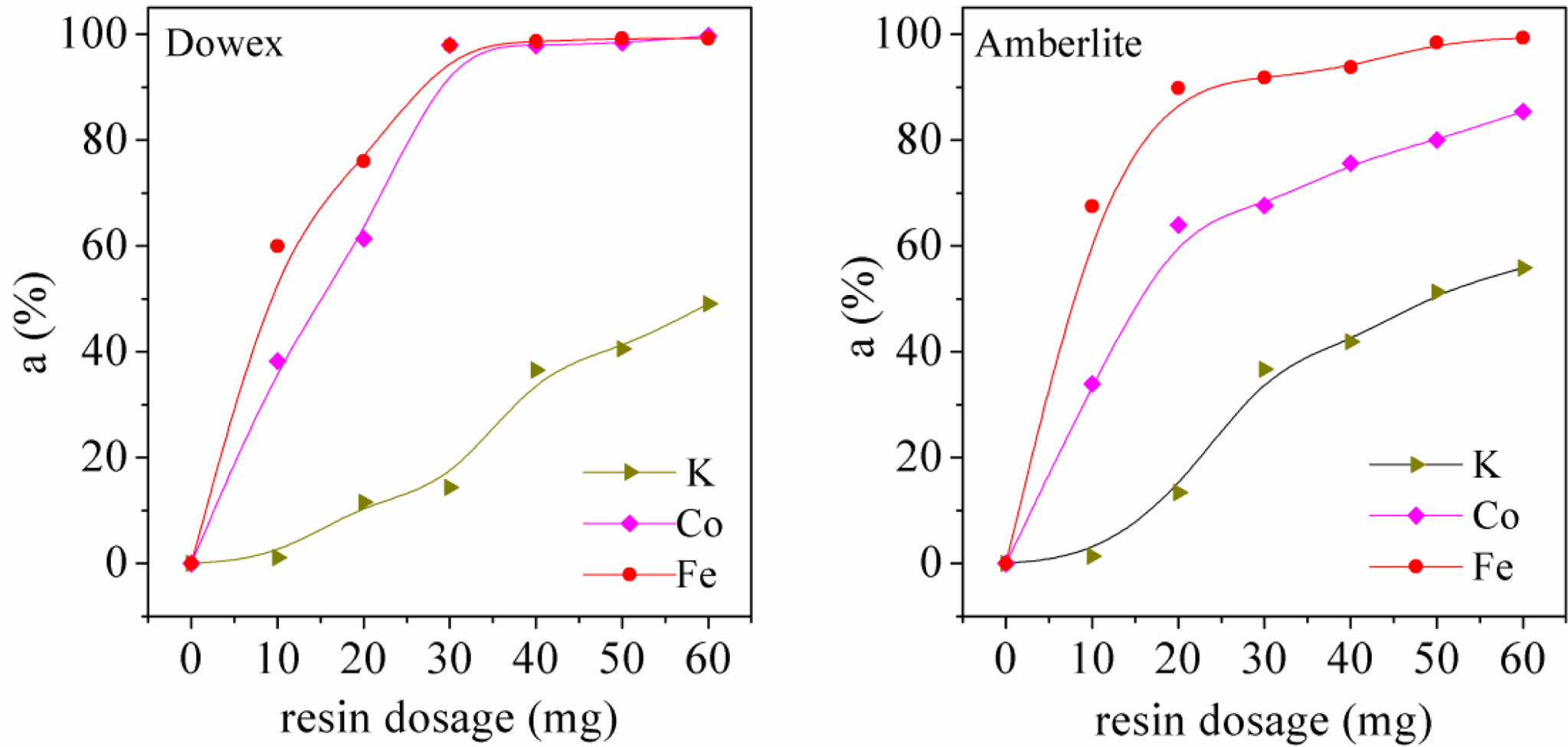

Effect

of Resin Dosage: The effects on the amount of resin have also been studied in this work.

The results are shown in Figure 4. It was apparent that the adsorption of

Fe(III) was affected greatly as the resin dosage increase. The adsorption ratio

increased along with the quantity of resin, which is because the larger surface

area and adsorption sites were provided by more resins, enhancing the removal

of Fe(III). When the resin dosage was 50 mg in the 100 mL aqueous solution, the

maximum adsorption of iron was 99.9% for Dowex 50WX2 200-400 (H) and 99.3% for

Amberlite IRP-69. Meanwhile, the Fe(III) was almost completely adsorbed with 50

mg Dowex 50WX2 200-400 (H).

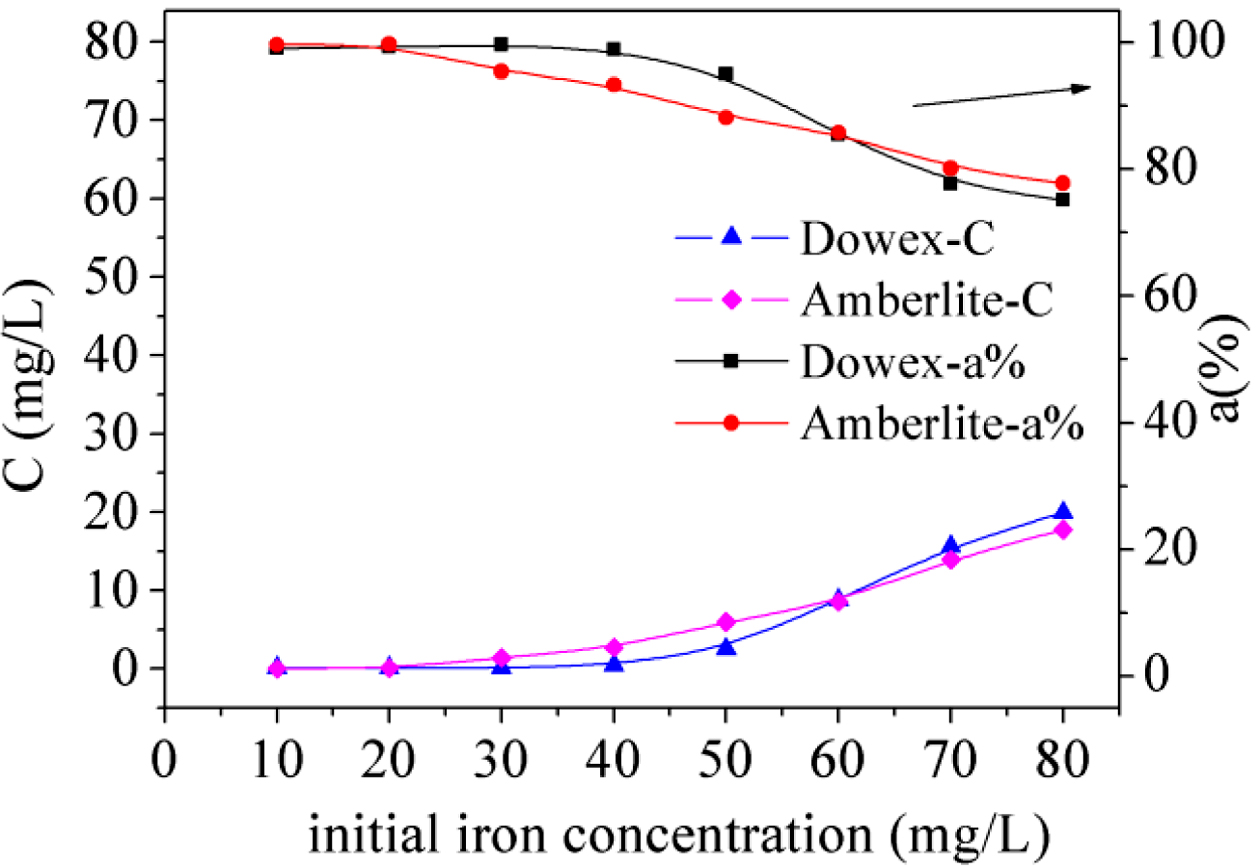

Effect

of Iron Concentration:

Different Fe(III) concentrations usually have different influences on the

adsorption ratio. Figure 5 demonstrates the effects of changing Fe(III)

concentration from 10 to 80 mg/L. The results show that the adsorption ratio

kept close to 99.9% as the Fe(III) concentration was below 40 mg/L for Dowex

50WX2 200-400 (H). A higher concentration is not favorable for Fe(III)

adsorption by the two resins. This is because with more Fe(III), the

availability of sites provided by the limited resins is not sufficient. Fe(III)

ions were residual in the solution, resulting in the lower adsorption ratio. It

can be seen that Fe(III) was easily removed from the aqueous solution by ion

exchange but cannot be separated efficiently by precipitation or membrane

filtration at lower concentrations.

Adsorption

Isotherms. Comparing the absorption ratio of Fe(III) with Dowex

50WX2 200-400 (H) and Amberlite IRP-69 in different conditions, it is found

that Dowex 50WX2 200-400 (H) showed better adsorption capacity for Fe(III) with

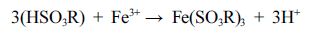

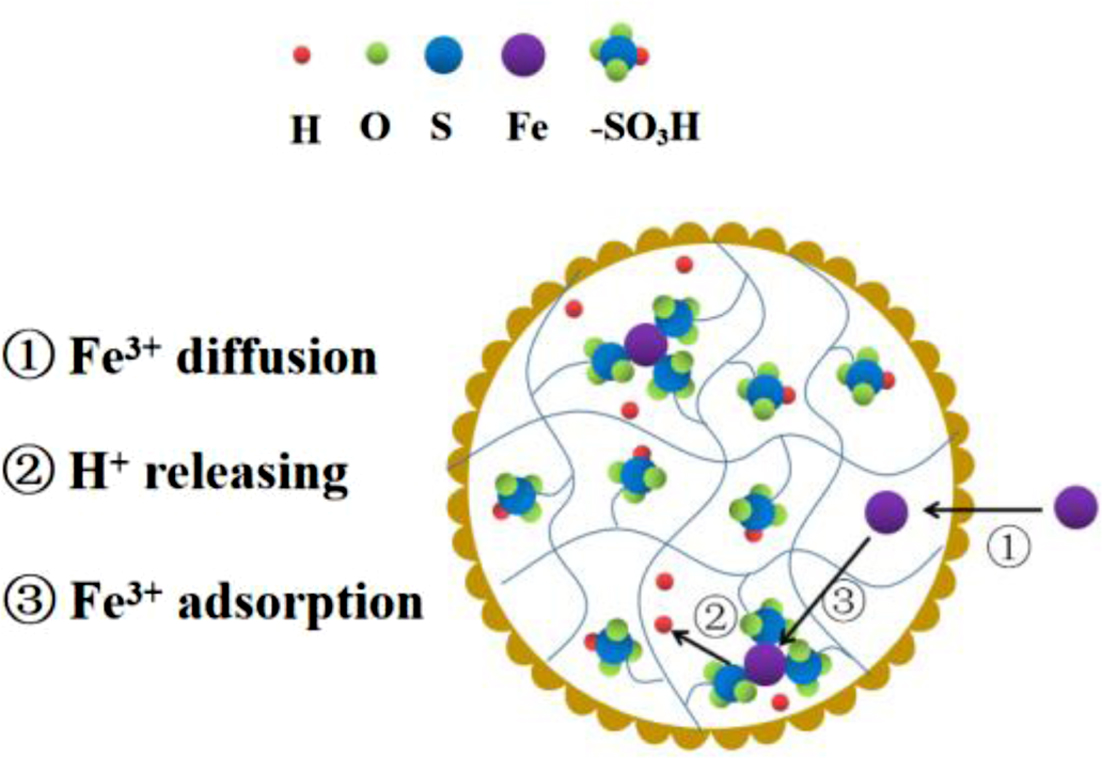

the optimum conditions. The adsorption mechanism of the Fe(III) with strong

acid cation resin can be represented as the formula (2), and a process of

Fe(III) adsorption is displayed in Figure 6. (2)

(2)

As shown in Figure 6, the Fe(III) is adsorbed by the functional group

with H+ being released when going through the resin. The Langmuir

and Freundlich isotherm models were introduced to understand the mechanism of

Fe(III) adsorption by Dowex 50WX2 200-400 (H) and Amberlite IR-120. The

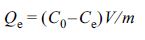

adsorption capacity23 at equilibrium Qe (mg/g) was

calculated as follows:

(3)

(3)

where V (mL) is the volume of the solution, m (mg) is the

weight of the resin dried, and Ce (mg/L) is the equilibrium

concentration.

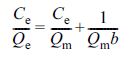

The Langmuir model was described as eq. (4). (4)

(4)

where b (L/mg) is Langmuir constant related to the affinity and Qm

(mg/g) is maximal adsorption capacity.

The Freundlich model was described as eq. (5). (5)

(5)

where n is Freundlich constant and K is Freundlich binding

constant.

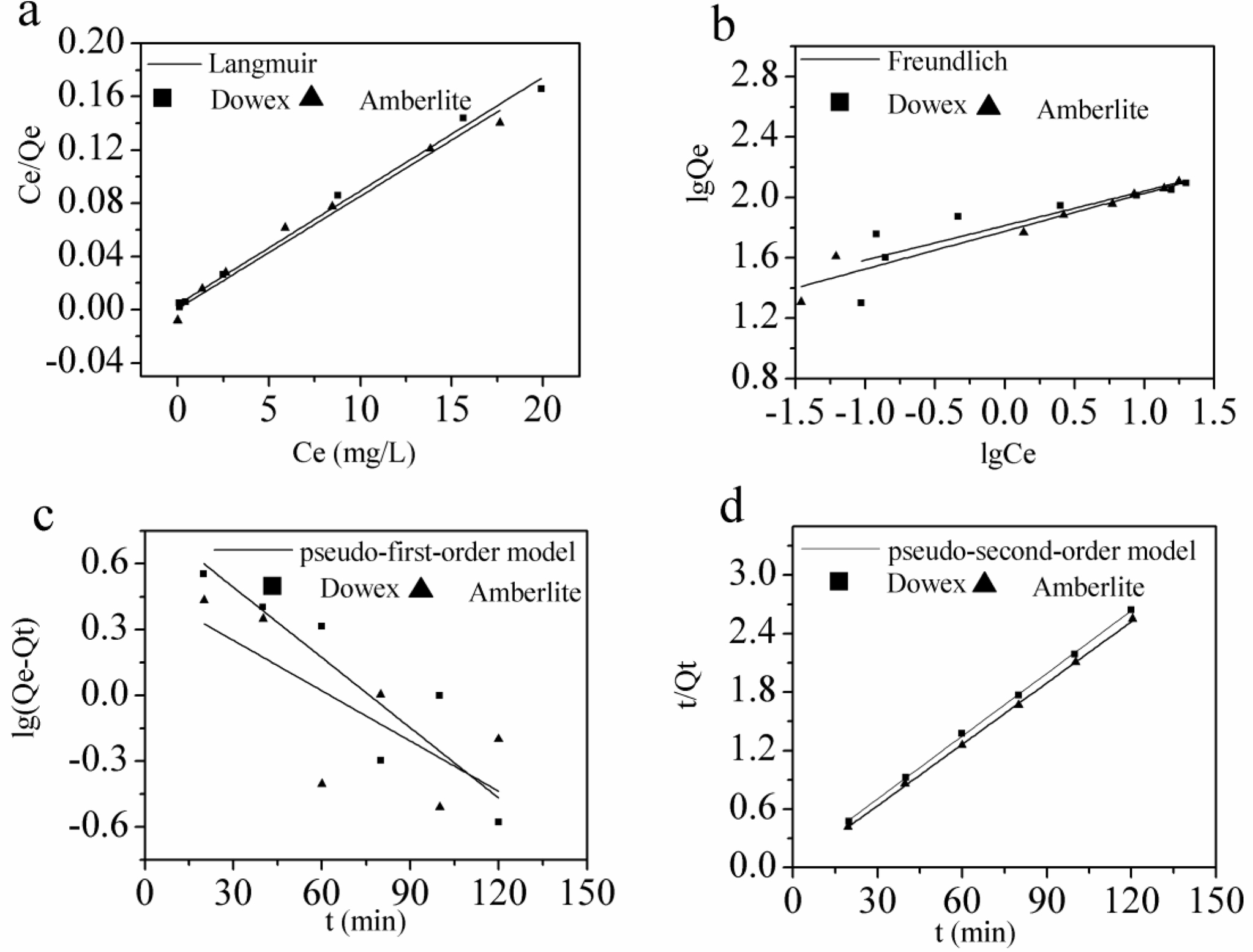

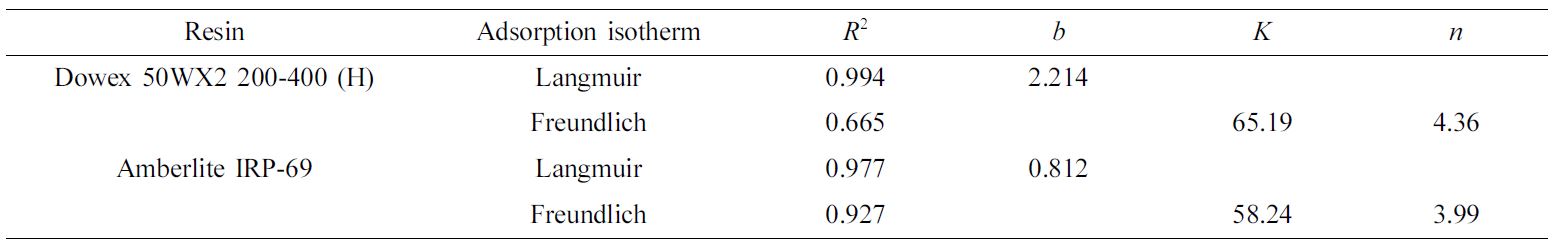

The adsorption data is shown with the model fit using the two isotherms

with resins adsorption of Fe(III) in Figure 7(a , b). The model parameters were

obtained by regression and indicated in Table 3. It was proven that Langmuir

isotherm represents a better fit of Fe(III) adsorption than the Freundlich

isotherm. Therefore, the Langmuir model was sufficient to describe the

adsorption of Fe(III) within the range of the errors permitted.

The Langmuir adsorption isotherm indicates that the adsorption is

monolayer and there is no other molecular coating, which is consistent with the

experimental results of Fe(III) concentration effects on adsorption ratio. More

ions cannot be adsorbed with the increasing of ion concentration because the

active sites are completely occupied. It also demonstrates that the probability

that an ion is absorbed at one site is independent of whether adjacent spaces

have been occupied by other ions. Therefore, the Fe(III) adsorption ratio would

increase with the increasing time until equilibrium state.

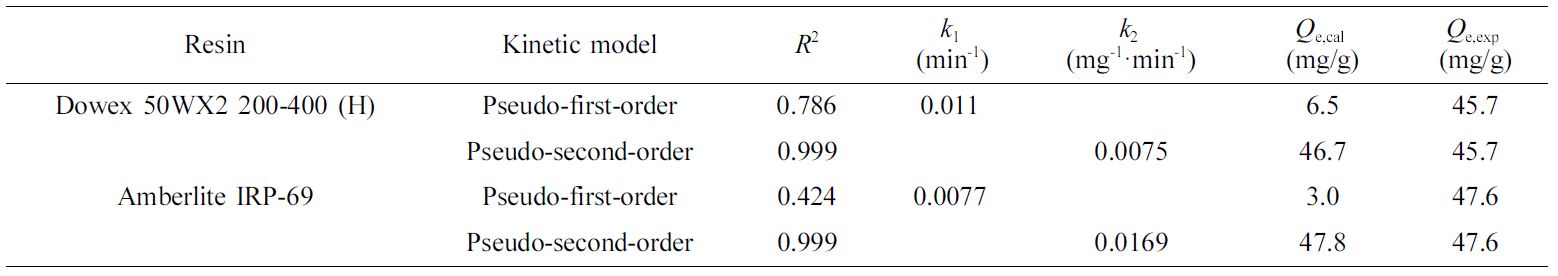

Adsorption

Kinetics. The adsorption

kinetic behavior of Fe(III) by Dowex 50WX2 200-400 (H) and Amberlite IRP-69 was

described with the pseudo-first-order model and the pseudo-second-order model.24,25

The pseudo-first-order model was described as eq. (6): (6)

(6)

The pseudo-second-order model was described as eq. (7): (7)

(7)

where Qe (mg/g) is adsorption capacity at equilibrium, Qt

(mg/g) is adsorption capacity at the time t, k1 (min-1)

is rate constant of the pseudo-first-order model, and k2

(g·mg-1·min-1) is rate constant of the

pseudo-second-order model.

The pseudo-first-order model and the pseudo-second-order model were

fitted in Figure 7(c, d) and the parameters are revealed in Table 4. Depending

on the experimental data, it was found that the correlation coefficient (R2>0.999)

of the pseudo-second-order model is higher than that of pseudo-first-order

model, and the equilibrium adsorption capacity calculated by

pseudo-second-order model (Qe,cal) is closer to the

experimental one (Qe,expl). These two points illustrate that

the pseudo-second-order model fits well the adsorption of Fe(III) by Dowex

50WX2 200-400 (H) and Amberlite IRP-69.

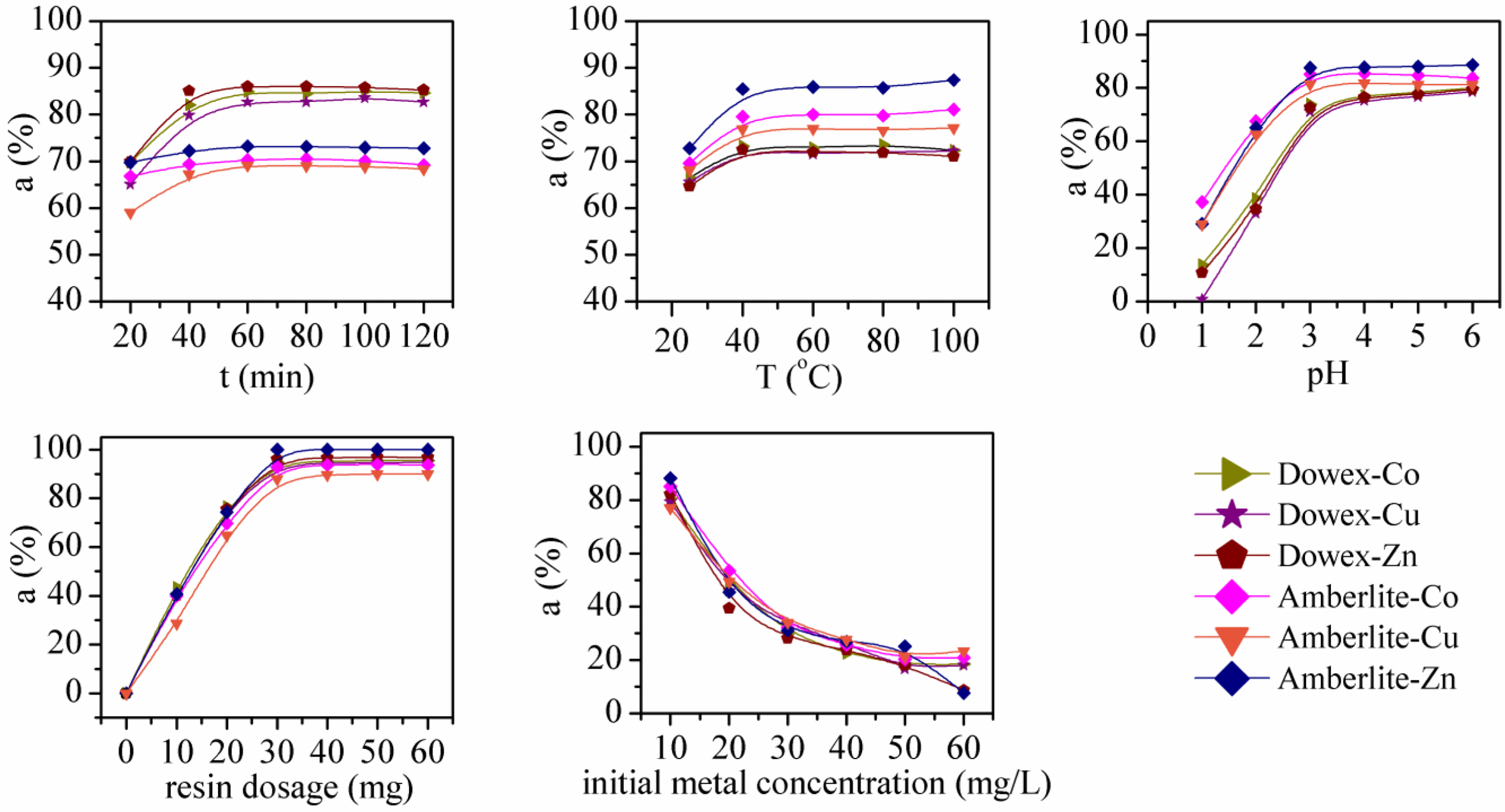

Selective Adsorption in Multi-metal Systems. Co(II), Cu(II), and Zn(II) Adsorption in 2-MMS: The adsorption of

Co(II), Cu(II), Zn(II) by Dowex 50WX2 200-400 (H) and Amberlite IRP-69 resins

from aqueous solution in different conditions was also explored in this study.

The aim was to evaluate the influencing factors and the adsorption behaviors of

resin for multiple metals. The results in 2-MMS are shown in Figure 8. It is

found that pH, resin dosage and initial concentration of metal ions have

greater effects on the adsorption ratios of the three ions. The adsorption

ratios of each metal increased with increase of pH and resin dosage but

decreased with increased initial metal concentration. This is coincident with

the conclusion obtained from Fe(III) adsorption in single-metal system. It is

also found that for each experimental factor changed, Dowex 50WX2 200-400 (H)

and Amberlite IRP-69 have similar adsorption ratios for each metal, and both

resins did not exhibit obvious selectivity for individual metal ions in 2-MMS.

This may be due to the same valence state of the three ions, which affects the

selectivity of the resins.

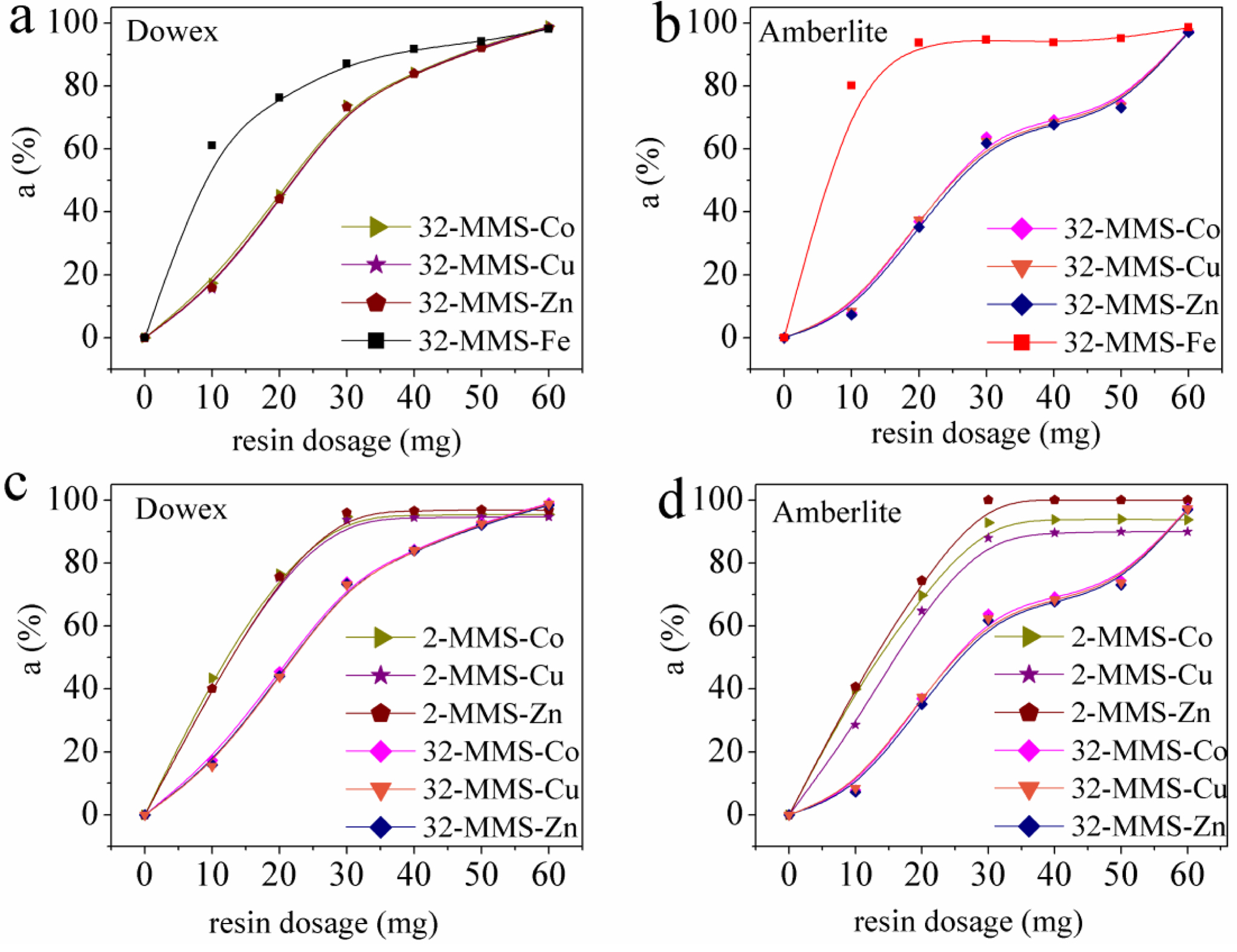

Fe(III),

Co(II), Cu(II), and Zn(II) Adsorption in 32-MMS. In order to

explore the adsorption behaviors for metals with different valence in multi-metal

systems, and to further verify that the selectivity of the resin is related to

the valence state, Fe(III), Co(II), Cu(II), and Zn(II) adsorption in 32-MMS was

carried out, and the respective adsorption ratio of four ions is shown in

Figure 9(a, b). The adsorption results described as: Fe(III) > Co(II) =

Cu(II) = Zn(II). Both resins exhibit the same adsorption selectivity for

Co(II), Cu(II), and Zn(II) in 32-MMS, which is consistent with the results of

previous studies. The resins showed a much better selectivity for Fe(III) in

the same conditions. It confirmed that the valence state of metals really

affects the selectivity of the resin. Metal ions of the same valence state lead

to the similar adsorption ratio, and metal ions of higher valence state are

more selectively adsorbed by resins. Therefore, the Fe(III) reached adsorption

equilibrium first with increasing of the resin dosages, after which Co(II),

Cu(II), and Zn(II) followed.

Comparing the results of Co(II), Cu(II), and Zn(II) adsorption in 2-MMS

and in 32-MMS by Dowex 50WX2 200-400 (H) and Amberlite IRP-69 in Figure 9(c, d). The results showed that the ratios of Co(II), Cu(II), and Zn(II) adsorption

in 2-MMS were higher than those in 32-MMS, and the adsorption ratio of each

metal in 32-MMS was reduced by about 20% than those in 2-MMS. The above results

can be explained as “competitive adsorption” when multiple metal ions coexist

in the solution, which is expressed that a negative effect on the adsorption

ratio of the metal in the original system happened when one or more metal ions

were added to the solution. This is because when two or more metal ions are

mixed in the solution, each metal ion competes for the functional groups on

resins at the same time, creating “competitive adsorption”. Therefore, the

adsorption ratio of each metal decreased with the limited amount of functional

group.

Fe(III),

Co(II), and K(I) Adsorption in 321-MMS. The adsorption of

Fe(III), Co(II), and K(I) in 321-MMS by Dowex 50WX2 200-400 (H) and

Amberlite IRP-69 in 100 mL aqueous solution was further studied. The three metals

are in different valence states. The aim is to verify that the higher valence

state of metals, the higher adsorption ratio, and the better selectivity of

resins. The results are shown in Figure 10. The adsorption ratio of each metal

with the same amount of resins in the aqueous solution is: Fe(III) > Co(II)

> K(I). The selectivity of resin for ferric iron is greater than that of

divalent cobalt, and the adsorption of divalent cobalt is greater than that of

monovalent potassium, which is due to the different adsorption force by

functional groups. Three equivalents of H+ from -SO3H

group were consumed for exchange when one equivalents of Fe(III) was adsorbed,

and it is easy to form a stable structure of three chemical bonds. However, a

monovalent or divalent ion requires fewer functional groups when adsorbed, and

with a weak adsorption force, it is difficult to bond or easily to fall off

after being adsorbed. Combining the results from 32-MMS, it is confirmed that

ions with different valence states result in different adsorption ratios, and

the high-valence metal ions are selected preferentially than low-valence metal

ions.

|

Figure 1 Effect of contact time on adsorption of Fe(III) (iron concentration = 10 mg/L, 25 ℃, 20 mg/100 mL, pH = 2). |

|

Figure 2 Effect of temperature on adsorption of Fe(III) (iron concentration = 10 mg/L, 20 mg/100 mL, pH = 2, 100 min). |

|

Figure 3 Effect of pH on adsorption of Fe(III) (iron concentration = 10 mg/L, 20 mg/100 mL, 100 min, 60 ℃ for Dowex resin, 80 ºC for Amberlite resin). |

|

Figure 4 Effect of resin dosage on adsorption of Fe(III) (iron concentration = 10 mg/L, 100 min, pH = 3, 60 ℃ for Dowex resin, 80 ℃ for Amberlite resin). |

|

Figure 5 Effect of iron concentration on adsorption of Fe(III) (50 mg/100 mL, 100 min, pH = 3, 60 ℃ for Dowex resin, 80 ℃ for Amberlite resin). |

|

Figure 6 Process of Fe(III) adsorption with strong acid cation resin. |

|

Figure 7 Adsorption model (Langmuir-a, Freundlich-b); The kinetics (pseudo-first-order model-c, pseudo-second-order model-d) for Fe(III) adsorption. |

|

Figure 8 Adsorption ratio of Co(II), Cu(II), Zn(II) with different contact time, temperature, pH, resin dosage and initial concentration in 2-MMS. |

|

Figure 9 Comparison of adsorption ratios of Fe(III), Co(II), Cu(II), Zn(II) in multi-metal systems. |

|

Figure 10 Selective adsorption ratio of Fe(III), Co(II), K(I) in 321-MMS. |

|

Table 4 Parameters of Pseudo-first-order and

Pseudo-second-order Models for Fe(III) Adsorption |

Adsorption of Fe(III), Co(II), Cu(II), Zn(II), and K(I) was studied to

investigate the adsorption behaviors and mechanism in single-metal and

multi-metal systems. The influencing factors of contact time, temperature, pH,

resin dosage, and metals concentration were investigated to enhance the

adsorption ratio of resins. The results showed that Dowex 50WX2 200-400 (H) had

a stronger affinity and higher selectivity for Fe(III). This occurred when the

contact time was 100 min ([Fe(III)] < 40 mg/L, resin amount = 50 mg, pH

= 3.0, 60 ℃), with the maximum adsorption ratio for Fe(III) being over 99.9%.

Mechanism studies showed that Langmuir isotherms model and

pseudo-second-order-kinetic equation fit well in the Fe(III) adsorption of

single-metal system. Due to the simple operation, mild reaction conditions, and

high selectivity of Dowex 50WX2 200-400 (H) and Amberlite IRP-69, the

adsorption can be applied to the separation of Fe(III) from aqueous solution.

The results in multi-metal systems showed that Dowex 50WX2 200-400 (H)

and the Amberlite IRP-69 resins reveal a weak affinity for the three metals and

the similar adsorption ratios for the metal ions of the same valence state. It

is proved that the resins demonstrate higher selectivity for metal ions of

higher valence. The new findings and adsorption rules will benefit the treatment

of industrial wastewater and recovery of metals from spent catalysts.

- 1. K. Petya and R. Djingova, Anal. Chim. Acta, 464,7 (2002).

-

- 2. J. Yu, J. D. Zheng, Q. F. Lu, X. Wang, X. M. Zhang, Q.Z. Wang, and W. Yang, Polym. Korea, 41, 480 (2017).

-

- 3. A. N. Nikoloski, K. L. Ang, and D. Li, Hydrometallurgy,152, 20 (2015).

-

- 4. L.L. Tavlarides, J. H. Bae, and C. K. Lee, Sep. Sci. Technol., 22,581 (1987).

-

- 5. M.Amara and H. Kerdjoudj, Desalination, 168, 195 (2004).

-

- 6. K. Sarangi, P. K. Parhi, E. Padhan, A. K. Palai, K. C.Nathsarma, and K. H. Park, Sep. Purif. Technol., 55, 44 (2007).

-

- 7. Y. Zhang, Q. Liu, and L. Li, Hydrometallurgy, 164,154 (2016).

-

- 8. P. P. Sun, T. Y. Kim, B. J. Min, H. I. Song, and S. Y. Cho, Mater. Transact., 56, 1863 (2015).

-

- 9. M. D. Víctor-Ortega, J. M. Ochando-Pulido, and A.Martínez-Ferez, J. Ind. Eng. Chem., 36, 298 (2016).

-

- 10. R. Chiariza, E. P. Horwitz, S. D. Alexandrators, andM. J. Gula, Sep. Sci. Technol., 22, 581 (1997).

-

- 11. C. Lasanta, I. Caro, and L. Pérez, Chem. Eng. Sci.,60, 3477 (2005).

-

- 12. T. H. Nguyen, S. H. Sohn, and M. S. Lee, Mater. Transact., 54, 1750 (2013).

-

- 13. A.-A. S. Aboul-Magd, S. A.-R. Al-Husain, and S. A.Al-Zahrani, Arab. J. Chem., 9, S1 (2016).

-

- 14. L. Duclos, L. Svecova, V. Laforest, G. Mandil, and P.X. Thivel, Hydrometallurgy, 160, 79 (2016).

-

- 15. P. P. Sun, T. Y. Kim, B. J. Min, and S. Y. Cho, Mater.Transact., 56, 738 (2015).

-

- 16. A. Dabrowski, Z. Hubicki, P. Podkoscielny, and E.Robens, Chemosphere, 56, 91 (2004).

-

- 17. S. Edebali and E. Pehlivan, Powder Technol., 301,520 (2016).

-

- 18. S. Veli and B. Pekey, Fresenius Environ. Bull.,13, 244 (2004).

- 19. A. Demirbas, E. Pehlivan, F. Gode, T. Altun, and G.Arslan, J. Colloid Interface Sci., 282, 20 (2005).

-

- 20. M. S. Lee and M. J. Nicol, Hydrometallurgy, 86,6 (2007).

- 21. Y. Fan, X. Wang, and M. Wang, Hydrometallurgy,136, 31 (2013).

-

- 22. G. Karthikeyan, N. M. Andal, and K. Anbalagan, J.Chem. Sci., 117, 663 (2005).

-

- 23. M. Parijaee, M. Noaparast, K. Saberyan, and S. Z.Shafaie-Tonkaboni, Korean J. Chem. Eng., 31, 2237 (2014).

-

- 24. Q.T. Bui, Y. S. Jeon, D. Kim, and J. H. Kim, Polym.Korea, 40, 275 (2016).

-

- 25. H.-Y. Li, C. Li, M. Zhang, K. Wang, and B. Xie, Hydrometallurgy, 165, 381 (2016).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2023 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2019; 43(6): 862-871

Published online Nov 25, 2019

- 10.7317/pk.2019.43.6.862

- Received on Jun 19, 2019

- Revised on Sep 2, 2019

- Accepted on Sep 9, 2019

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Qinmin Pan

-

Green Polymer and Catalysis Technology Laboratory, College of Chemistry, Chemical Engineering and Materials Science, Soochow University, Suzhou 215123, Jiangsu Province, People’s Republic of China

- E-mail: qpan@suda.edu.cn

- ORCID:

0000-0001-5410-6845

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.