- GO Enhanced, Irradiation Cross-linked UHMWPE/VE Nanocomposites with Increased Hardness and Scratch Resistance

Binjiang College, Nanjing University of Information Science & Technology, Wuxi 214105, China

*School of Mechanical Engineering, Jiangnan University, Wuxi 214122, China- GO 강화 및 조사 가교된 UHMWPE/VE 나노복합재료의 경도와 스크래치 저항의 증가

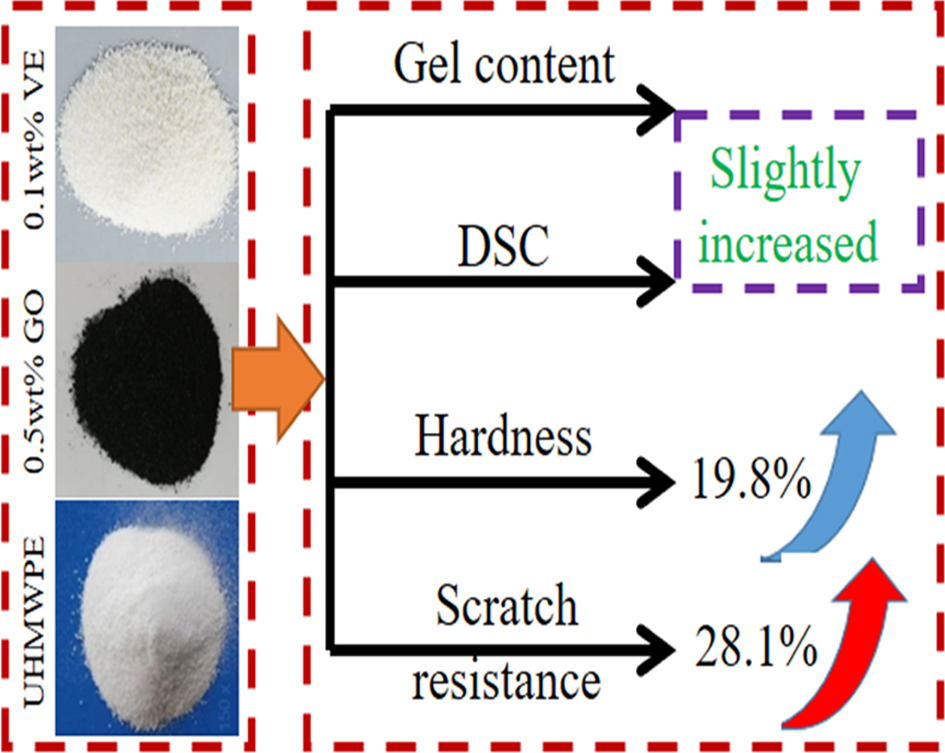

In this study, a way to

reinforce the properties of ultrahigh molecular weight polyethylene

(UHMWPE)/vitamin E (VE) nanocomposites was put to use by adding graphene oxide

(GO) combined with gamma-ray irradiation cross-linking. The influences of

adding GO and irradiation cross-linking treatment on the thermal and mechanical

properties were studied, especially the effect of GO doping on irradiation

cross-linked UHMWPE/VE nanocomposites. The results show that GO filling has no

significant effect on melting temperature and gel content decreased at a small

degree, but the crystallinity has been improved obviously. In addition, the

ball indentation hardness and scratch resistance were enhanced as well. The

comprehensive effects of improved crystallinity and reduced cross-linking

degree as well as the good mechanical properties of GO doping were responsible

for this result.

A way to reinforce the properties of ultrahigh molecular

weight polyethylene (UHMWPE)/Vitamin E (VE) nanocomposites was put to use by

adding graphene oxide (GO) combine with gamma-ray irradiation crosslinking. GO

filling has no significant effect on melting temperature and gel content

decreased at a small degree, but the crystallinity has been improved obviously.

In addition, the ball indentation hardness and scratch resistance were enhanced

as well.

Keywords: graphene oxide, UHMWPE/vitamin E nanocomposites, irradiation cross-linking, hardness, scratch resistance

This study is supported by the Additive Manufacturing

Products Supervision and Inspection Center of Jiangsu Province, Wuxi

Institution of Supervision & Testing on Product Quality, Wuxi, China.

Irradiation cross-linked ultra-high molecular weight polyethylene/vitamin

E (UHMWPE/VE) composite has been widely used in total joint arthroplasty (TJA)

as its excellent thermal stability, anti-oxidation and wear resistance.1

However, the existence of VE would stabilize and absorb free radicals generated

during irradiation process, which results in the decrease of cross-linking

degree of the composite. The decline of cross-linking degree will lead to the

decrease of mechanical properties, such as hardness and scratch resistance, and

bring about adverse effect to the joint prosthesis in the long-term service. In

order to solve those problems, researchers have devoted a lot of efforts, such

as Yang and Lee.2,3 Oral et al. studied the irradiation

cross-linked UHMWPE blends with 0.1 wt% and 0.3 wt% VE respectively,

the result shows that although the oxidation resistance increased,

cross-linking degree of the material decreased with the increase of VE content,

and mechanical properties reduced as well.4,5 Besides the

cross-linking degree, crystallinity is also one of the factors affecting the

properties of materials. Oral et al. showed that the tensile and fatigue

properties of irradiated cross-linked UHMWPE/VE composites are linearly and

positively correlated with the crystallinity.6 Doshi et al. improved

the crystallinity of irradiated cross-linked UHMWPE/VE composites to ameliorate

the fatigue resistance and tribological properties by high pressure

crystallization process.7 Fu et al. researched the influence

of high temperature melting treatment on irradiation cross-linked UHMWPE/VE

composites, the results show that high temperature melting improved the

crystallinity, wear resistance and impact properties also enhanced company with

increased crystallinity.8 Although above methods improved the mechanical

and tribological properties to some extent, the high cost and tedious process

in the preparation process limited large-lot production. Therefore, there are

badly in need of a more advanced technique to modify irradiation cross-linked

UHMWPE/VE composites.

Graphene with good biocompatibility, mechanical properties and large

specific surface area, has been widely applied as a modifier to enforce polymer

matrix.9-12 However, the characteristics of easy clustering and

unfavorable dispersal restrict its application. Graphene oxide (GO), a

functionalized product of graphene, with excellent dispersion, thermal

stability and mechanical properties, has been used as a reinforcing agent for

UHMWPE material in recently years. Pang et al. fabricated 0.5 wt%

UHMWPE/GO composites by hot-pressing, and found that GO is well dispersed in

UHMWPE matrix.13 Moreover, the addition of GO improved not only the

thermal performance and crystallinity, but also the hardness of the composites.

Ni et al. investigated irradiation cross-linked UHMWPE by adding

0.5 wt% GO, showing that the addition of GO slightly increased the melting

temperature, but significantly increased the crystallinity.14 Huang et

al. studied the irradiation cross-linked GO/UHMWPE composites, and drew a

similar conclusion.15,16 Moreover, the results demonstrated that GO

could maintain the efficiency of cross-linking. Furthermore, the mechanical,

wear and anti-scratch properties enhanced as well. Besides, other researchers

also demonstrate that GO could improve the hardness and wear resistance of

UHMWPE.17-19

Based on those results mentioned above, we add 0.5 wt% GO into

0.1 wt% UHMWPE/VE composites before irradiation cross-linking. Looking

forward to maintaining the cross-linking degree of composites, meanwhile, with

excellent thermal stability and higher crystallinity to improve mechanical

properties of materials. In order to confirm whether the mechanical properties

of irradiation cross-linked UHMWPE/VE/GO composite can be strengthened or not,

the ball indentation hardness and scratch test are carried out. Since it is

closely related to the mechanical properties of materials, melting temperature,

crystallinity and cross-linking degree are also investigated in this study.

Materials

and Materials Preparation. Powdered UHMWPE

(GUR1050) has a density of 0.93 g·cm-3 with an average

molecular weight of five million and the mean particle diameter of about

140 μm, and was purchased from American Ticina Company. High-purity

graphite powder (99.9 wt%, 325 mesh) was provided by Qingdao Jinrilai Co.

Ltd. China, and was used to prepare GO. Other chemical reagents were analytical

grade and were supplied by Sinopharm Chemical Reagent Beijing Co., Ltd.

GO was prepared in accordance with the modified Hummers method.20

The irradiation cross-linked UHMWPE/VE/GO composites with the concentration of

0.1 wt% VE and 0.5 wt% GO was fabricated by means of liquid

ultrasonic dispersion, high speed ball milling, hot pressing molding and

irradiation cross-linked by γ-ray, the detailed steps are as follows: First of

all, 0.1 g VE and 0.5 g GO powder were placed in a beaker with

100 mL alcohol solution and ultrasonic treated for 0.5 h, then

99.4 g UHMWPE powder was added into the beaker and continue ultrasonic

treated for 1 h to obtain a homogeneous solution. Secondly, the mixed

solution was treated by high speed ball milling at a speed of 400 rpm for

2 h and then kept in a water bath at 60 oC to remove the

ethanol until the alcohol was completely evaporated. Thirdly, the mixture

powder was pressed in a model at 5 MPa for 0.25 h followed by heating

treatment at 200 oC for 2 h in a hot air oven, and then

pressed at 10 MPa until reached room temperature. Finally, the specimens

were cut into different sizes of samples then vacuum packed and irradiated by γ-ray

at a rate of 0.5 KGy/h at room temperature, the total irradiation dose was

100 KGy.

Gel

Content. According to ASTM D2765-01,21

the gel content after irradaition cross-linking of UHMWPE/VE/GO composites was

calculated in terms of the following formula.

where W0 is the quantity of sample before test, W

is the quantity of sample after test.

Differential

Scanning Calorimeter (DSC). DSC (TA, Q200) was

applied at a scanning rate of 10 oC/min from 20 to 200 oC

in the nitrogen atmosphere. The samples were heated to 200 oC

and held for 5 min to remove thermal history; then they were cooled to 20 oC;

finally they were heated to 200 oC. The crystallinity of

UHMWPE/VE/GO composites was calculated according to the following formula. The

crystallinity of UHMWPE/VE/GO composites before/after irradiation cross-linking

was calculated according to the following formula.

where f is the filler

content, DH is the melting

enthalpy of samples and DH0 is the enthalpy of

melting of a 100% crystalline UHMWPE with the data of 293 J/g.22

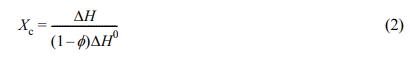

Ball

Indentation Hardness. The ball indentation hardness

of different composites were measured by the MFT-5000 tribometer and calculated

by the following equation according to the standard ISO2 039-73.23

where H is the indentation hardness of samples (N/mm2);

p is the maximum experimental force (N); D is the diameter of the

ball (mm); h is the maximum indentation depth (mm). The diagrammatic

sketch of ball indentation hardness test is shown in Figure 1.

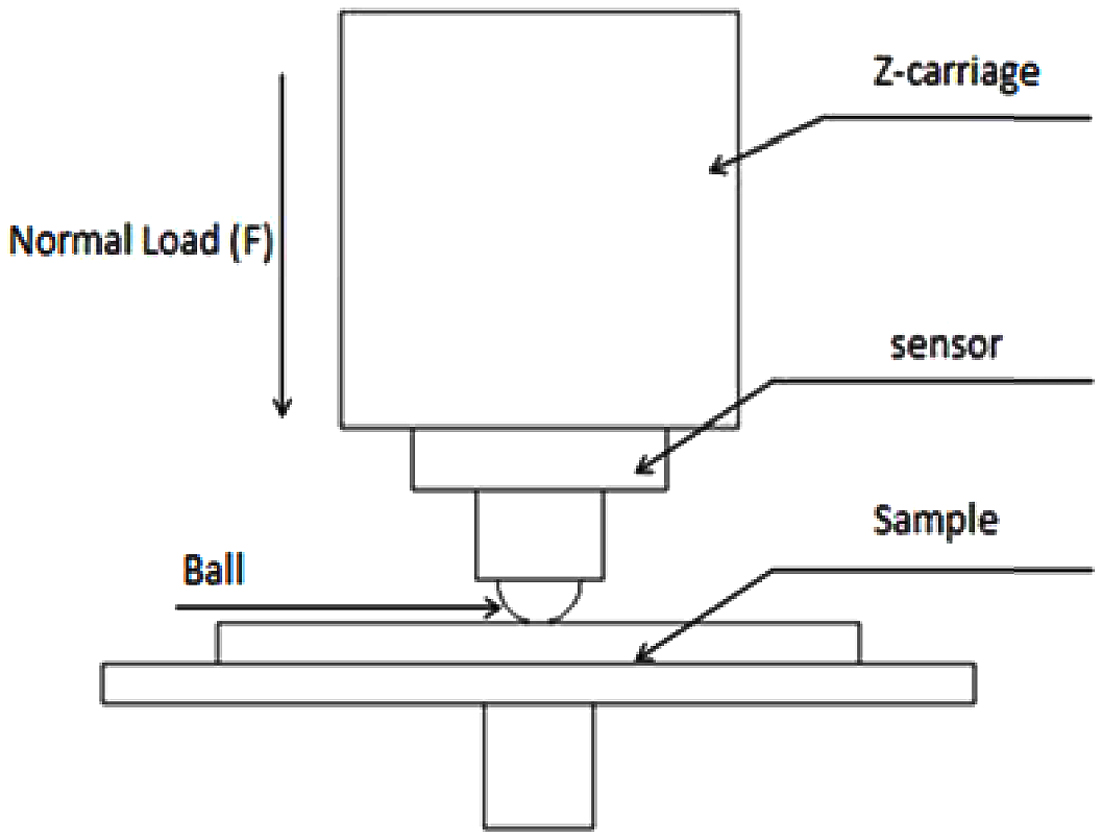

Scratch

Test. Scratch resistance is also a way to evaluate the

mechanical properties of materials. In this paper, the scratch test of

different composites was also measured by the MFT-5000 tribometer, the scratch

coefficient is calculated by the following equation.

where μ is scratch coefficient; FT is the

scratch resistance; FN is normal pressure. The diagrammatic

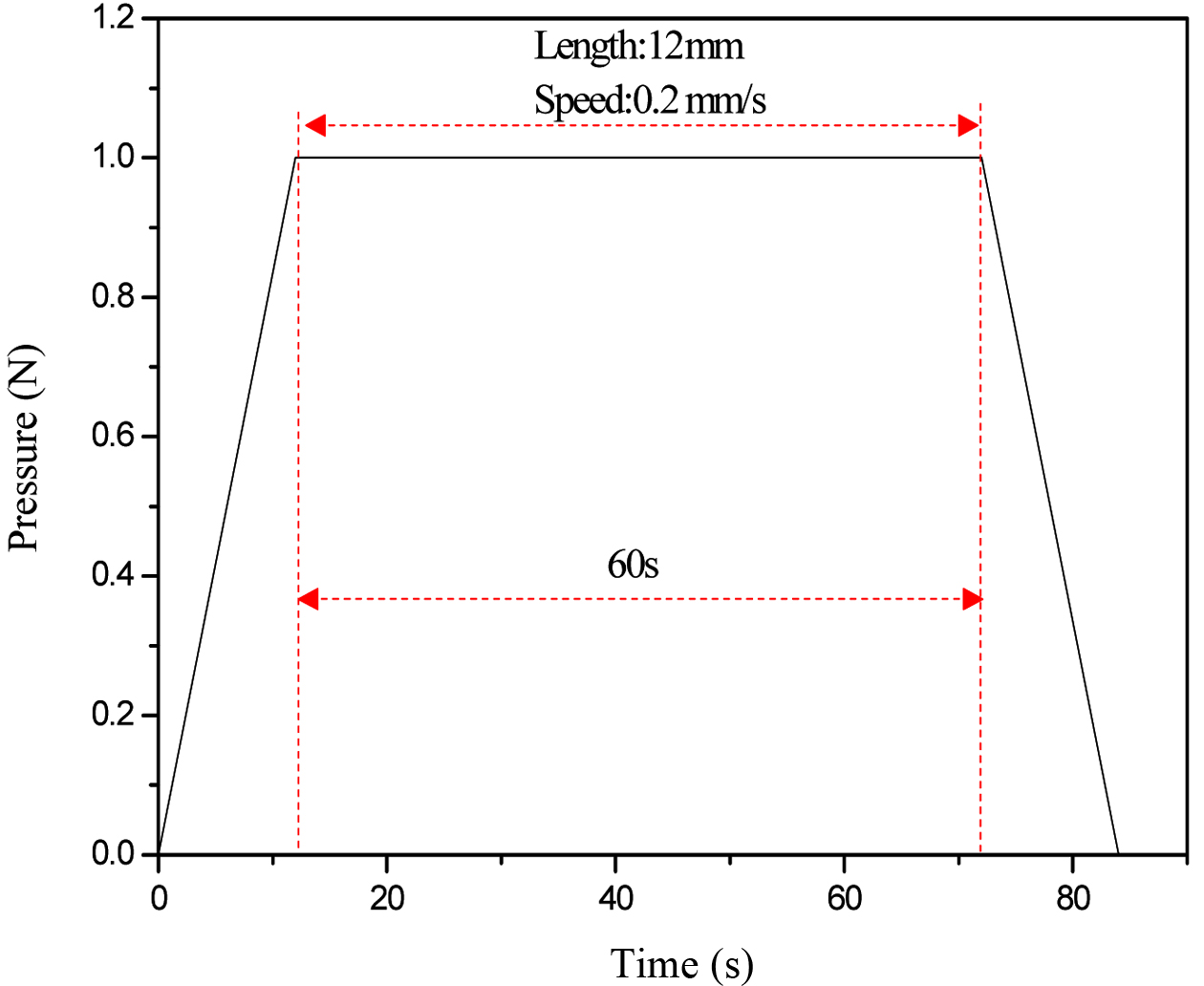

sketch of scratch test is shown in Figure 2.

The experimental load is 1 N with 12 mm scratching length at a

speed of 0.2 mm/s, MFD-D profilometer was used to scan the scratch

morphology after test. Diagrammatic sketch of parameters for scratch test is

shown in Figure 3.

|

Figure 1 Diagrammatic sketch of ball indentation hardness test. |

|

Figure 2 Diagrammatic sketch of scratch test. |

|

Figure 3 Diagrammatic sketch of parameters for scratch test |

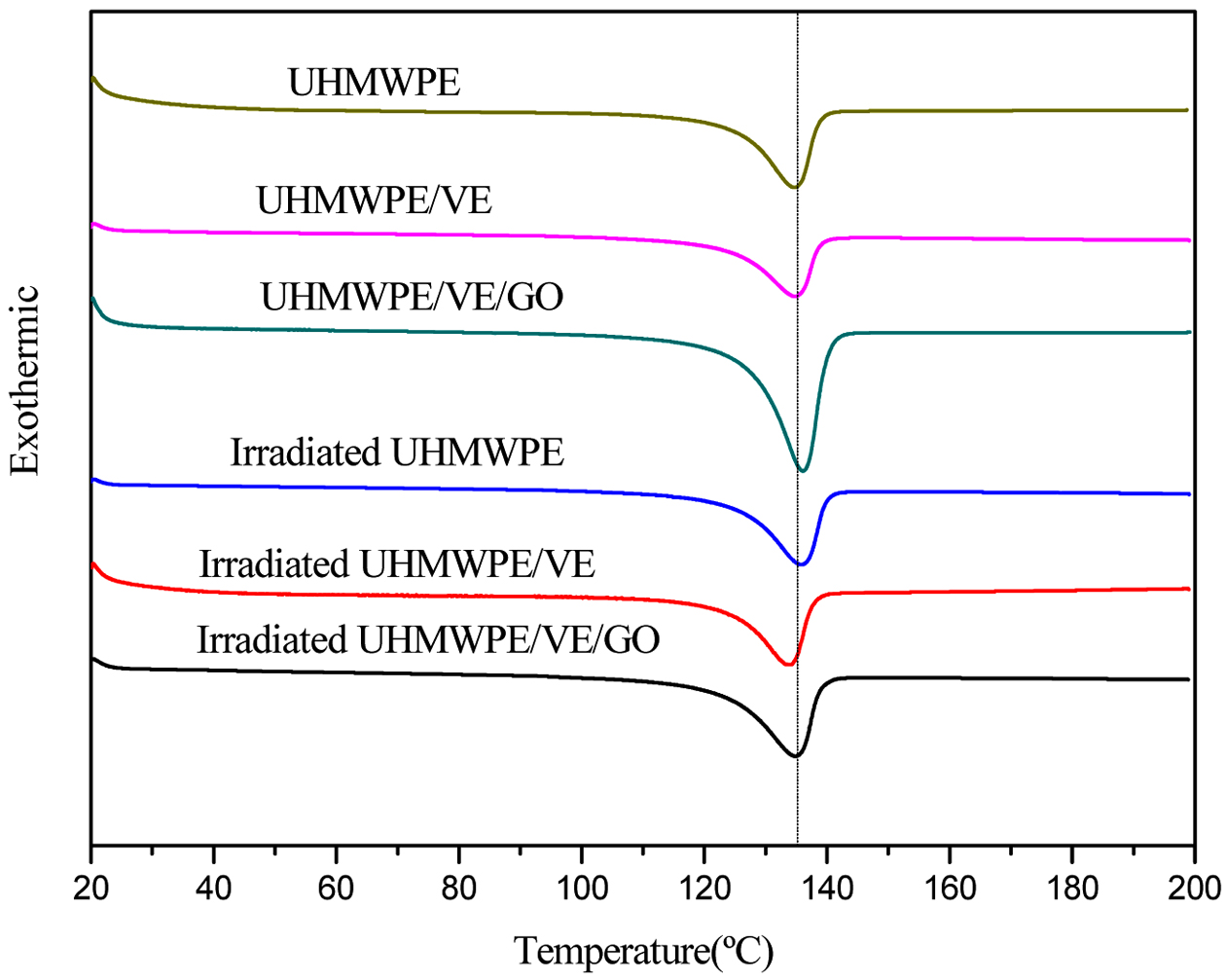

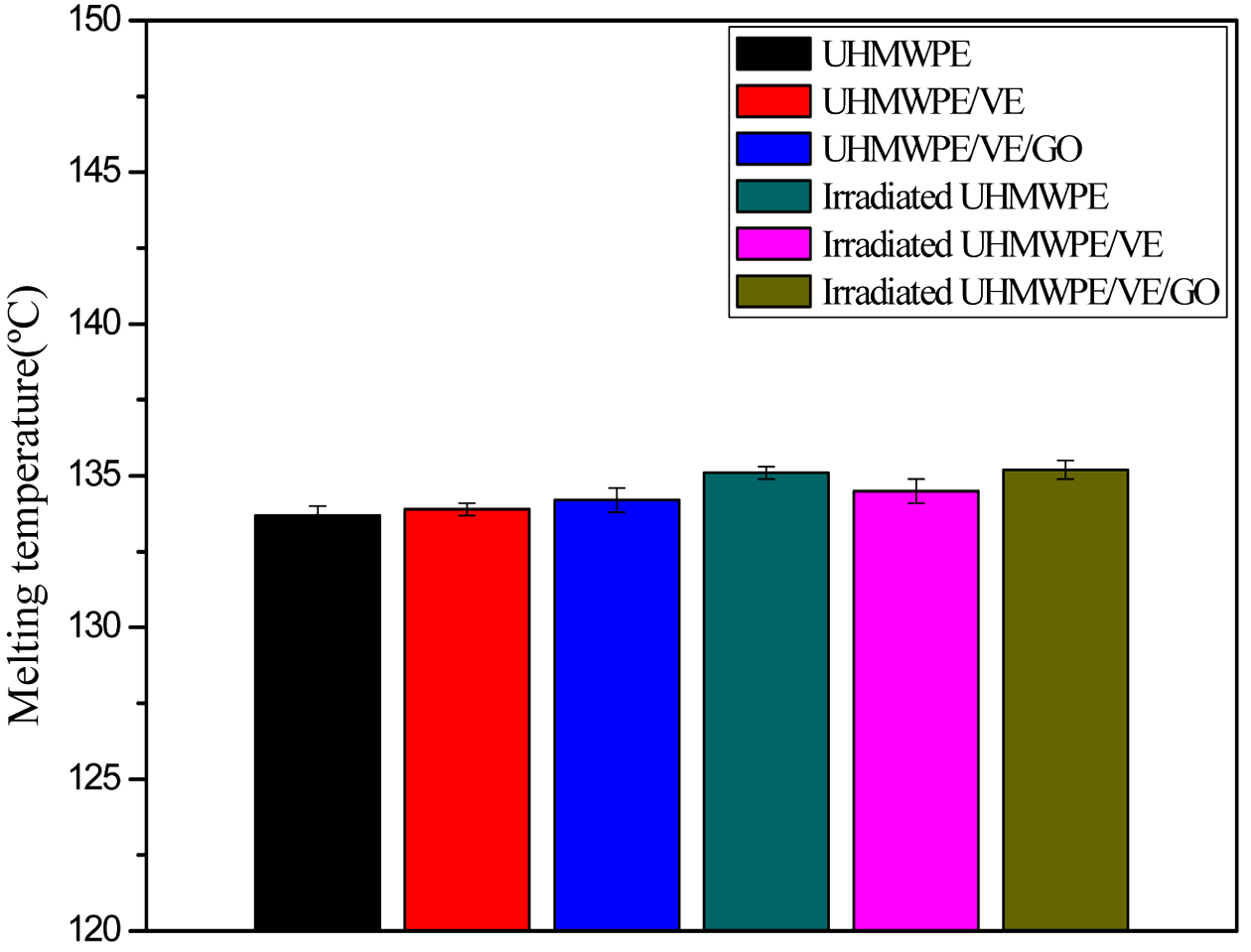

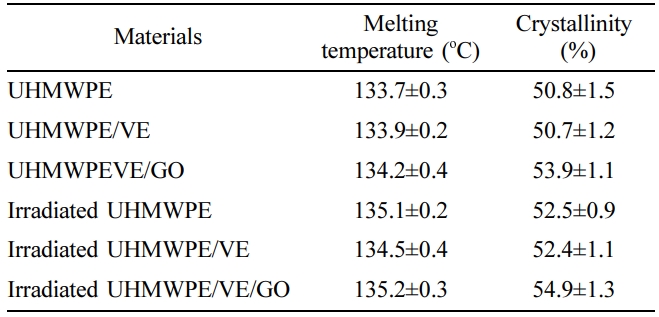

As substrate material for artificial joints, UHMWPE composites will

release heat which could affect the properties of materials due to friction in

long-term applications, in order to characterize the thermal stability of

irradiation cross-linked UHMWPE/VE/GO composites, the melting temperature and

crystallinity of different composites were studied by DSC, as shown in Figure

4-6 Figure 5 and Table 1. It should be noted that our previous research results show

that no degradation of VE occurred at this temperature condition.24,25

It can be seen that the melting temperature of pure UHMWPE was 133.7±0.3 oC,

the filling of VE and GO has unobvious effect on the melting temperature of

UHMWPE. Pang also illustrated the similar results that the filler of both VE

and GO has no significant impact on the melting temperature of UHMWPE.25

After irradiation cross-linking, the trend is almost the same to that of

non-irradiated UHMWPE composites. The melting temperature of both UHMWPE and

its composites were almost constant, this was due to the cross-linking reaction

of the fractured molecular chains in the amorphous region during irradiation,

which delays the melting process and increases the melting temperature.26

GO has capable of grafting to the molecular chain of irradiation cross-linked

UHMWPE/VE composites as its larger specific surface area, which could be able

to enhance interface adhesion of the composites.27 Therefore, the

melting temperature nearly remain unchanged.

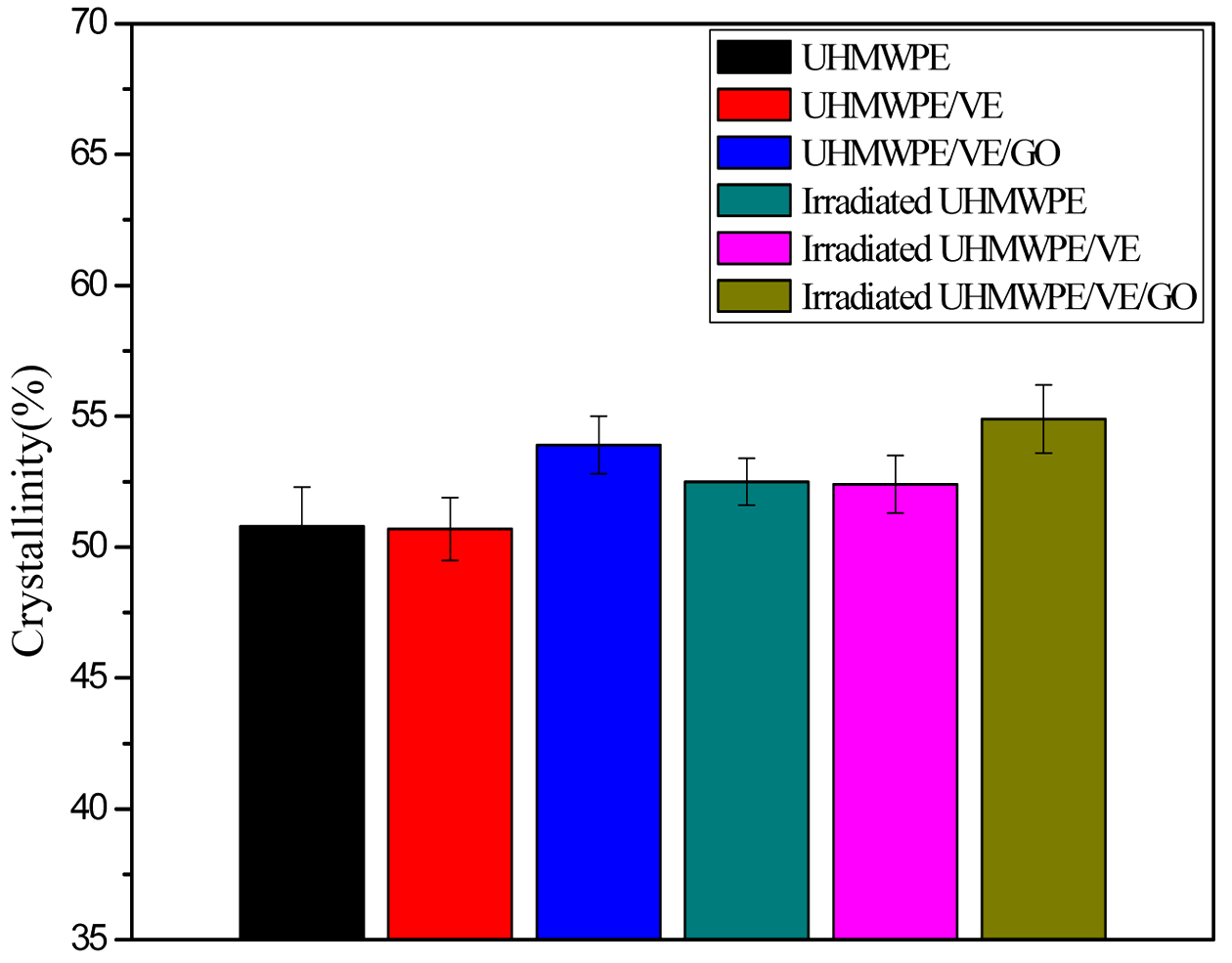

As shown in Table 1, the crystallinity of pure UHMWPE was 50.8±1.5

followed with 50.7±1.2 after adding VE, showing that VE filling has no obvious

effect on the crystallinity of UHMWPE, this result was analogous to the

findings of other researchers.28 A significantly increased

crystallinity emerged in composites after filling GO, compared with that of

unfilled. GO can turn into nucleation sites for crystallization as its large

specific surface area. In the crystallization process, GO gradually transforms

from microcrystalline region to larger crystal region around UHMWPE, which

promotes the increase of crystallinity of UHMWPE matrix. In addition, it can be

found that irradiation cross-linking not only increased melting temperature but

also crystallinity. A large number of fractured molecular chains recrystallized

to form more perfect crystals during irradiation, resulting in increased

crystallinity. Meanwhile, the crystallinity of irradiation cross-linked UHMWPE

was almost the same regardless of whether adding VE or not, showing that VE

hardly affects the change of crystallinity. However, the crystallinity improved

4.8% compared with irradiation cross-linked UHMWPE/VE composite after GO

filling. On the one hand, irradiation cross-linking disrupts the linear

molecular chain of UHMWPE and recrystallizes the broken molecular chain. On the

other hand, two-dimensional wrinkled GO with large specific surface area may

play a role in hindering the mobility of fractured molecular chains, gathering

on the surface of GO and increasing the recrystallization process.26

It is reported that the increase of crystallinity is beneficial to the

improvement of mechanical properties of UHMWPE matrix.6,7,29 Therefore,

the experimental results provide an effective theoretical support for further

study on the mechanical properties of irradiated cross-linked UHMWPE/VE/GO

composites.

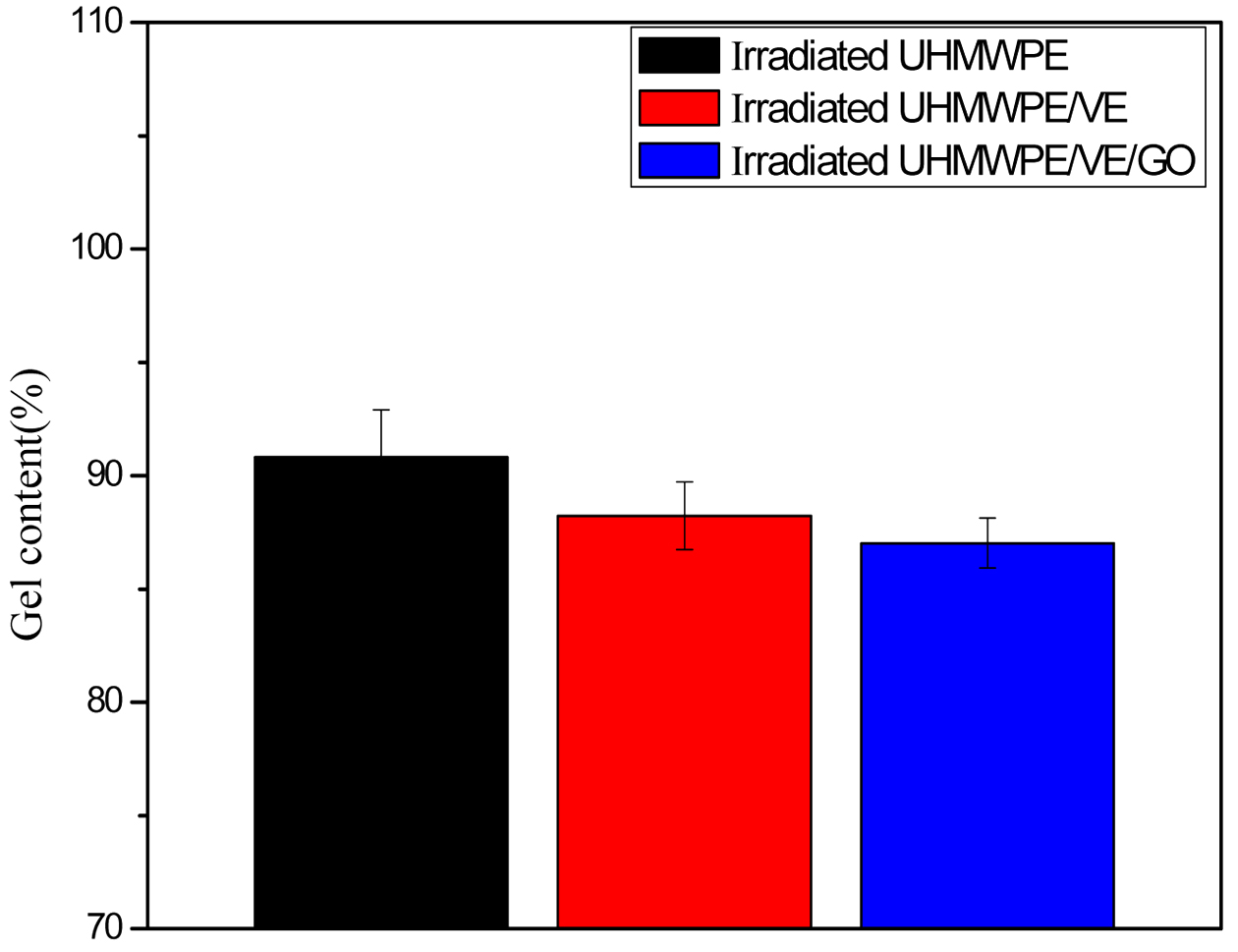

To a certain extent, cross-linking of composites can improve mechanical

properties. Therefore, for the sake of characterizing the cross-linking degree

of irradiated cross-linked UHMWPE/VE/GO composites, the gel content of the

composites was tested, as shown in Figure 7. The gel content of irradiation

cross-linked UHMWPE was 90.25% and with 2.9% decline after adding VE, the

result was similar to Oral.5 This was due to the ability to absorb

and stabilize free radicals of VE, hindering the cross-linking of free

radicals. After adding GO, the gel content of the irradiated cross-linked

UHMWPE/VE/GO composite decreased slightly, but it was not obvious. This may be

that the mobility of fractured molecule chain was hindered by the strong

interface binding force between GO and UHMWPE/VE matrix.14,26 Once

more, to some degree, GO composite has the function of scavenging free

radicals. In addition, Hyun studied the effect of g-rays on the

crystallinity of UHMWPE under different crystallization conditions.30

It was found that the crystallinity of UHMWPE increased whereas the amorphous

region of UHMWPE decreased, limiting the cross-linking of UHMWPE.31

To be specific, GO has moderating effect on gel content influencing the

composites, but the effect is not very significant.

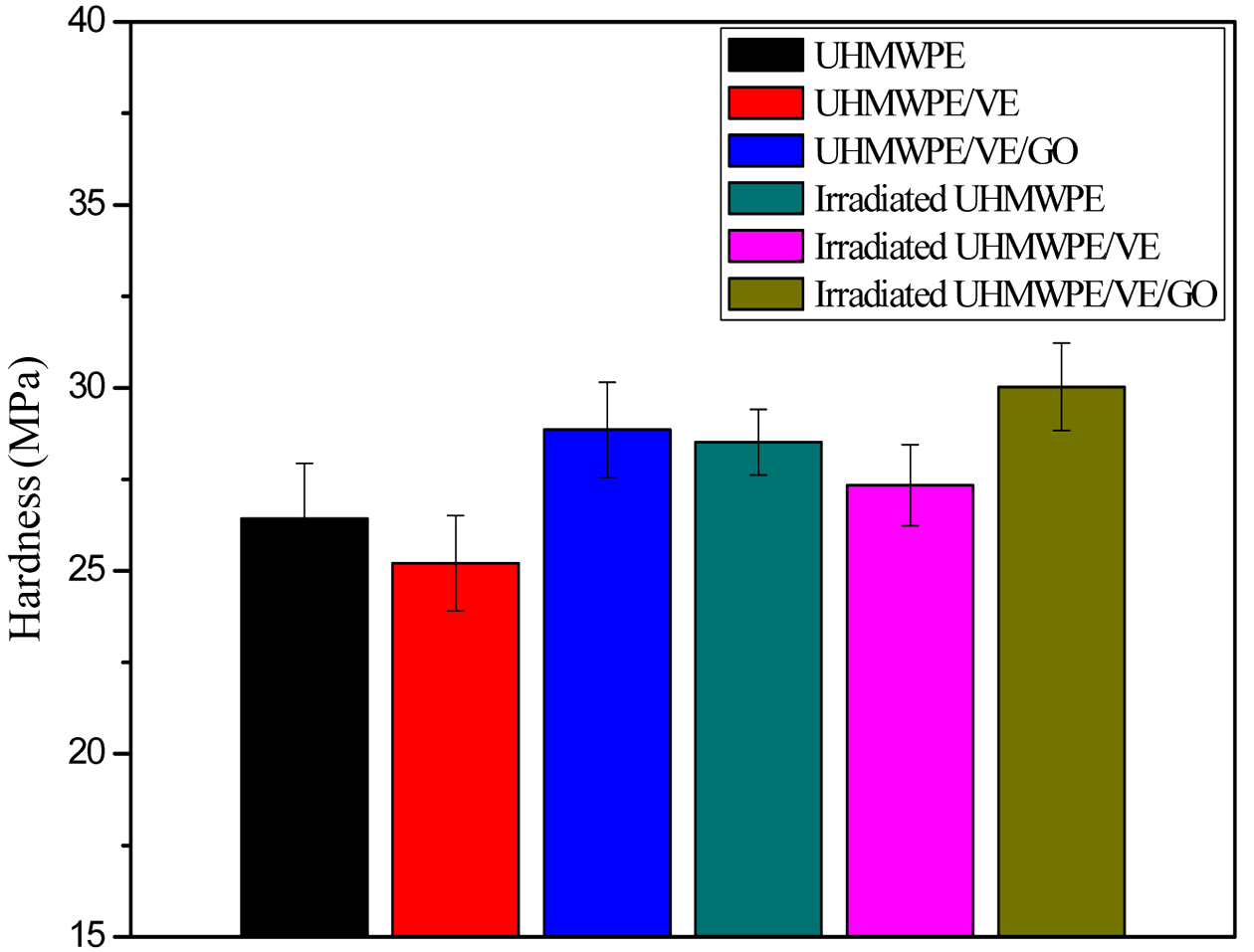

Figure 8 shows the ball indentation hardness of irradiation cross-linked

UHMWPE/VE/GO composites. It can be found that the filler of VE reduced the

hardness of UHMWPE slightly, but the hardness of the composites increased

significantly after GO filling. The hardness of pure UHMWPE is 26.43 MPa,

then decreased to 25.21 MPa after filling VE and increased to

28.86 MPa after filling GO. This was owing to the excellent mechanical

properties of GO, its wrinkled two-dimensional structure can withstand part of

the loads and transfer them to a larger layered structure.13-16,26

Although the hardness of the composites decreased after filling VE, the

addition of GO played a dominant role, and the combined effect of those two

factors resulted in the increase of the hardness. Irradiation cross-linking

increases the hardness of pure UHMWPE by 7.9%, and the hardness of irradiation

cross-linked composites changed from 27.34 MPa to 30.03 MPa after

filling VE and GO, respectively. This is due to the absorption of free radicals

by VE, resulting in the decrease of cross-linking degree.26 Although

the cross-linking degree of irradiated cross-linked UHMWPE is reduced by adding

VE, which is not conducive to the increase of hardness, UHMWPE inevitably

oxidizes and becomes brittle during irradiation process, which also reduces the

hardness of the material. The existence of VE effectively improves the

oxidation resistance of the material, and the two functions make the hardness

decrease in a very small range. As the excellent mechanical properties of GO,

the irradiation cross-linked UHMWPE/VE/GO composite possesses optimal hardness

compared with other materials. Furthermore, Buchanan pointed out that

the hardness of material is closely related to its crystallinity and increases

with the increased crystallinity, which is similar to our research.31

In addition, although GO filling slightly reduces the cross-linking density of

irradiation cross-linked UHMWPE/VE composites, whereas improves the hardness,

indicating that crystallinity plays a leading role in improving hardness of the

materials.

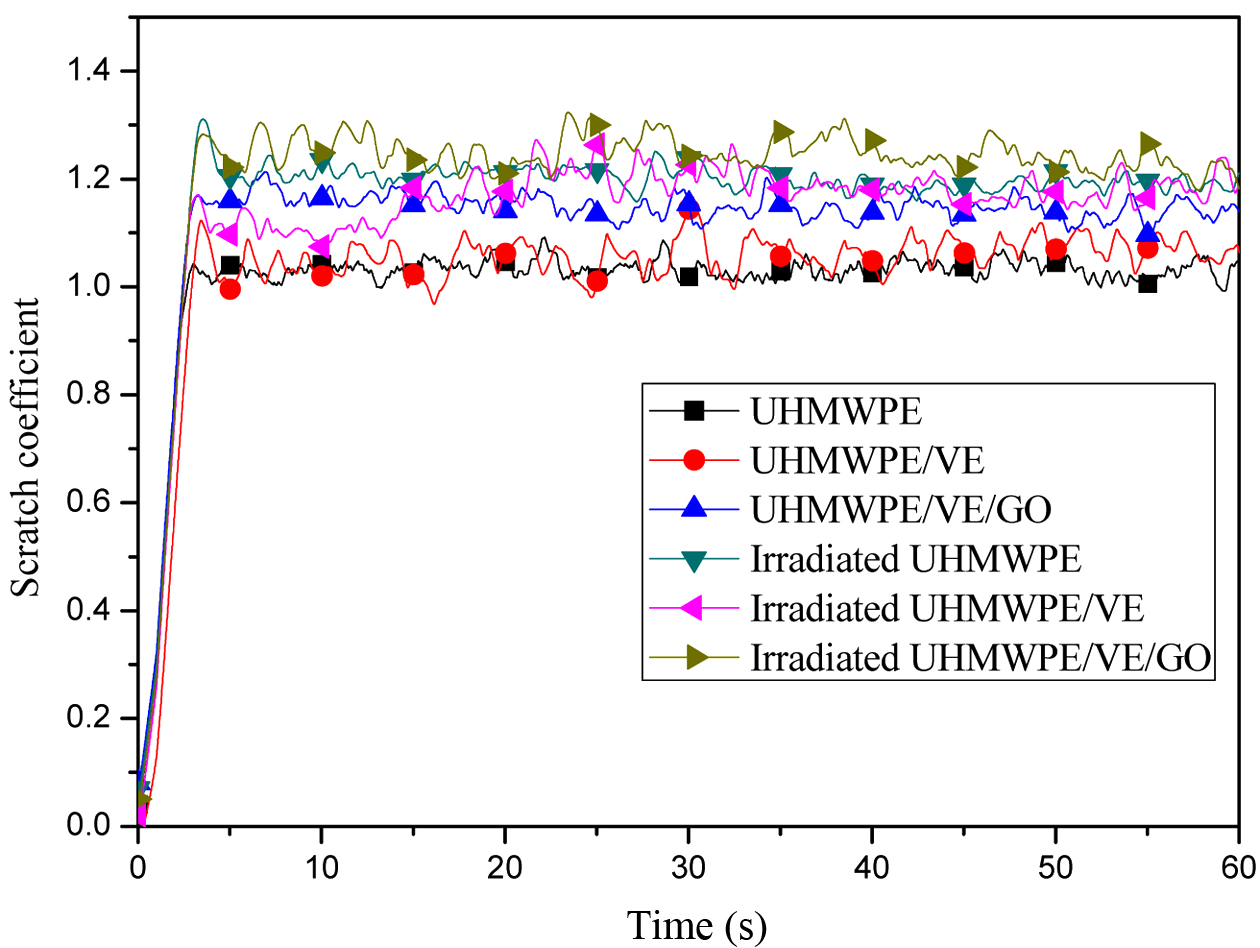

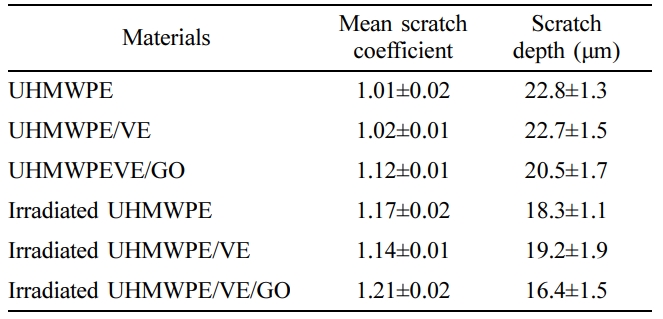

Figure 9 and Figure 10 show the scratch coefficient and morphology of

irradiation cross-linked UHMWPE/VE/GO composites, the specific data are shown

in Table 2. The result shows that the mean scratch coefficient vary from 1.01

to 1.21, and hardly changed after adding VE. It can be found that the addition

of VE has no effect on the scratch coefficient of pure UHMWPE, which is mainly

due to the unchanged crystallinity. However, the addition of GO led to an

increase of scratch coefficient of 11%. The wrinkled two-dimensional structure

of GO and the increased hardness of composite increase the sliding resistance

of probe in the matrix, the tiny van der Waals force between GO slice and

UHMWPE matrix is also one of the reasons for the increase of scratch coefficient.13

After irradiation cross-linking, the mean scratch coefficient increased to

1.17, it can be attributed to the cross-linking degree. The molecular chains

interrupted by γ-rays are recombined and cross-linked, which increases the

crystallinity and cross-linking degree of the matrix, the increase of hardness

resulted in the increase of scratch coefficient.15,16 Compared with

irradiation cross-linked UHMWPE, the scratch coefficient is reduced by 3% after

filling VE, this is mainly due to the decrease of cross-linking degree. The

irradiation cross-linked UHMWPE/VE/GO composite possesses maximum scratch

coefficient. On the one hand, the increased cross-linking degree and the

addition of GO increase the sliding force of probe, respectively. On the other

hand, while the UHMWPE molecular chains are interrupted during irradiation

process, the GO molecular chains are also interrupted generating GO free

radicals simultaneously, partial GO free radicals react with UHMWPE radicals to

form C-C bonds.14 The bond energy of the generated C-C bond is much

stronger than that of the van der Waals force, resulting in increased interface

bonding force, which further increased the scratch coefficient. Consequently,

those above factors result in the biggest scratch coefficient of the

irradiation cross-linked UHMWPE/VE/GO composite.

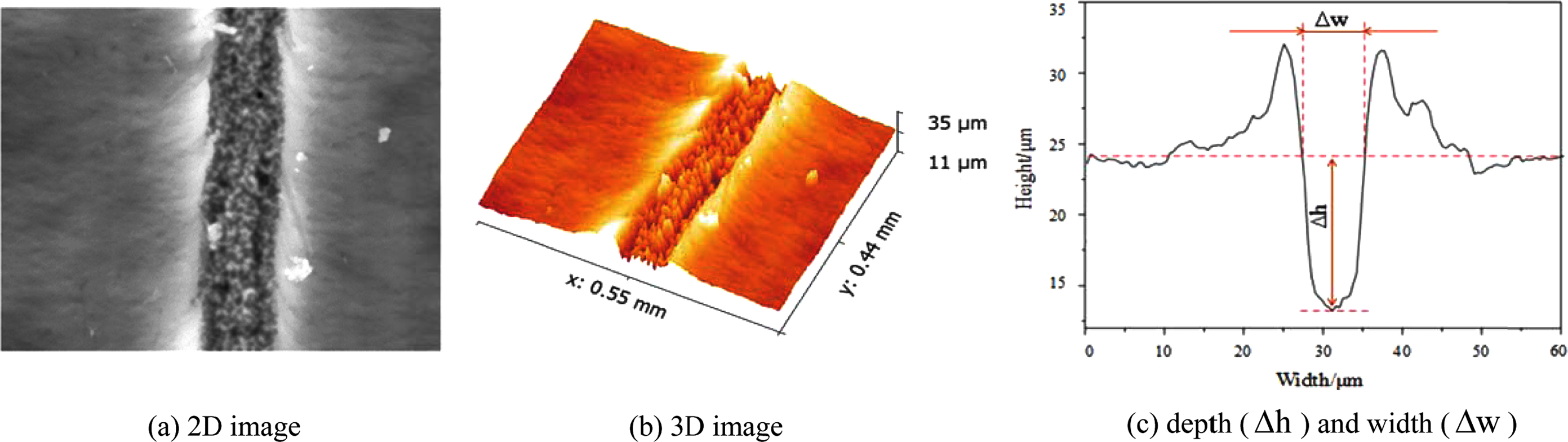

Compared with scratch coefficient, scratch depth presents the opposite

results, the scratch depth decreased from 22.8 to 16.4 μm, as shown in

Table 2. UHMWPE possesses the biggest depth, the addition of VE had no obvious

effect on the scratch depth of pure UHMWPE, however, irradiation cross-linking

and GO filling reduce the scratch depth obviously. The reason for this

phenomenon is similar to that of scratch coefficient.

Besides, another reason for the improvement of mechanical properties may

be nanoinclusion and nanoconfinement effects caused by the addition of GO, as

reported by Kim and Choe.32,33 After adding 0.5 wt% GO, composites

reveal improved mechanical properties owing to strong polymer–filler

interactions by virtue of large contact area caused by GO nanosheets. Since

nanoinclusion and nanoconfinement effects of interface boundary, UHMWPE polymer

and GO nanosheet composites have a very broad application prospects in

strengthening mechanical properties by increasing the interfacial area.

|

Figure 4 DSC curves of different materials. |

|

Figure 6 Crystallinity of different materials. |

|

Figure 5 Melting temperature of different materials. |

|

Figure 7 Gel content of different materials. |

|

Figure 8 Ball indentation hardness of different materials. |

|

Figure 9 Scratch coefficient of different materials. |

|

Figure 10 Scratch morphology of different materials. |

The emphasis of this work is the study of GO improving the mechanical

properties of irradiation cross-linked UHMWPE/VE composites. Adding GO into

UHMWPE/VE composites before irradiation cross-linking provided a practicable

approach to improve mechanical properties of irradiated UHMWPE/VE composites

while obtaining high hardness and scratch resistance. In this study,

irradiation cross-linked UHMWPE/VE composite was enhanced by filling GO. VE

filling decreased the gel content, resulting in a slight decrease of hardness

and scratching performance. The addition of GO slightly affected the melting

point and gel content of the composite, but to a small extent. However,

crystallinity shows distinct improvement. Due to the great mechanical

properties of GO, the hardness and scratch resistance improved 19.8% and 28.1%,

respectively. Meanwhile, irradiation cross-linking and GO filling can synergistically

enhance the thermal stability and mechanical properties of UHMWPE/VE

composites.

- 1. P. Bracco and E. Oral, Clin. Orthop. Relat. Res., 469, 2286 (2011).

-

- 2. D. H. Yang, G. H. Yoon, G. J. Shin, S. H. Kim, J. M. Rhee, G. Khang, and H. B. Lee, Macromol. Res., 13, 120 (2005).

-

- 3. H. S. Lee, J. H. Park, J. H. Yim, H. J. Seo, and T. W. Son, Polym. Korea, 39, 23 (2015).

-

- 4. E. Oral, B. W. Ghali, S. L. Rowell, B. R. Micheli, A. J. Lozynsky, and O. K. Muratoglu, Biomaterials, 31, 7051 (2010).

-

- 5. E. Oral, E. S. Greenbaum, A. S. Malhi, W. H. Harris, and O. K. Muratoglu, Biomaterials, 26, 6657 (2005).

-

- 6. E. Oral, C. A. G. Godleski, A. J. Lozynsky, A. S. Malhi, and O. K. Muratoglu, Biomaterials, 30, 1870 (2009).

-

- 7. B. N. Doshi, B. Ghali, B. C. Godleski, A. J. Lozynsky, E. Oral, and O. K. Muratoglu, Macromol. Mater. Eng., 300, 458 (2015).

-

- 8. J. Fu, B. N. Doshi, E. Oral, and O. K. Muratoglu, Polymer, 54, 199 (2013).

-

- 9. C. Lee, X. Wei, J. W. Kysar, and J. Hone, Science, 321, 385 (2008).

-

- 10. A. K. Geim, Science, 324, 1530 (2009).

-

- 11. C. N. Rao, A. K. Sood, K. Subrahmanyam, and A. Govindaraj, Angew. Chem. Int. Ed., 48, 7752 (2009).

-

- 12. X. Zhou and F. Liang, Curr. Med. Chem., 21, 855 (2014).

-

- 13. W. C. Pang, Z. F. Ni, G. M. Chen, G. D. Huang, H. D. Huang, and Y. W. Zhao, RSC Adv., 5, 63063 (2015).

-

- 14. Z. F. Ni, W. C. Pang, G. M. Chen, P. P. Lu, and S. H. Qian, Russ. J. Appl. Chem., 90, 1876 (2017).

-

- 15. G. D. Huang, Z. F. Ni, G. M. Chen, W. C. Pang, and Y. W. Zhao, Int. J. Polym. Anal. Charact., 21, 417 (2016).

-

- 16. G. Huang, Z. Ni, G. Chen, and Y. Zhao, Int. J. Polym. Sci., 2016, 2618560 (2016).

-

- 17. Y. F. Chen, Y. Y. Qi, Z. X. Tai, X. B. Yan, F. L. Zhu, and Q. J. Xue, Eur. Polym. J., 48, 1026 (2012).

-

- 18. Z. X. Tai, Y. F. Chen, Y. F. An, X. B. Yan, and Q. J. Xue. Tribol. Lett., 46, 55 (2012).

-

- 19. S. Su, R. Joffe, J. L. Tipper, and N. Emami, Composites B, 78, 18 5 (2015).

-

- 20. W. S. Hummers and R. E. Hummers, J. Am. Chem. Soc., 80, 1339 (1958).

-

- 21. Annual Book of ASTM Standards, ASTM D2765-01 (2001).

- 22. B. Wunderlich, Macromol. Phys., New York, Academic Press, Vol 3 (1980).

- 23. J. W. Gooch, ISO 2039-B, 61, 399 (2011).

-

- 24. G. M. Chen, Z. F. Ni, and S. H. Qian, Ind. Lubr. Tribol., 5, 68 (2016).

-

- 25. W. C. Pang, J. L. Wu, Q. F. Zhang, and G. F. Li, RSC Adv., 7, 55536 (2017).

-

- 26. V. Premnath, W. H. Harris, M. Jasty, and E. W. Merrill, Biomaterials, 17, 1741 (1996).

-

- 27. C. Turner, Alexander, and Tomohiro, J. Biomech. Sci. Eng., 10, 1 (2015).

- 28. A. George, H. D. Ngo, and A. Bellare, J. Mech. Behav. Biomed. Mater., 40, 406 (2014).

-

- 29. E. Kolanthai, S. Bose, K. S. Bhagyashree, S. V. Bhat, K. Asokan, D. Kanjilal, and K. Chatterjee, Phys. Chem. Chem. Phys., 17, 22900 (2015).

-

- 30. K. P. Hyun and Y. C. Nho, Radiat. Phys. Chem., 60, 79 (2001).

-

- 31. F. J. Buchanan, J. R. White, B. Sim, and S. Downes, J. Mater. Sci.-Mater. Med., 12, 29 (2001).

-

- 32. J. H. Choe, J. Jeon, M. E. Lee, J. J. Wie, H. J. Jin, and Y. S. Yun, Nanoscale, 10, 2025 (2018).

-

- 33. S. K. Kim, J. J. Wie, Q. Mahmood, and H. S. Park, Nanoscale, 6, 7430 (2014).

-

- Polymer(Korea) 폴리머

- Frequency : Bimonthly(odd)

ISSN 0379-153X(Print)

ISSN 2234-8077(Online)

Abbr. Polym. Korea - 2022 Impact Factor : 0.4

- Indexed in SCIE

This Article

This Article

-

2020; 44(5): 589-595

Published online Sep 25, 2020

- 10.7317/pk.2020.44.4.589

- Received on Oct 15, 2019

- Revised on Dec 29, 2019

- Accepted on Jun 1, 2020

Services

Services

- Full Text PDF

- Abstract

- ToC

- Acknowledgements

Introduction

Experimental

Results and Discussion

Conclusions

- References

Shared

Correspondence to

Correspondence to

- Jitai Han

-

Binjiang College, Nanjing University of Information Science & Technology, Wuxi 214105, China

- E-mail: hanjitai@hotmail.com

- ORCID:

0000-0003-3081-5764

Copyright(c) The Polymer Society of Korea. All right reserved.

Copyright(c) The Polymer Society of Korea. All right reserved.